Preparation method of film coating fresh-keeping agent for cold storage freshwater fish slices, product made by preparation method and application of preparation method

A technology of coating preservatives and freshwater fish fillets, which is applied in the direction of preserving meat/fish with a coating protective layer, can solve the problems of high price of natural preservatives, influence on the sensory quality of fish fillets, and increased production costs for enterprises, and achieves maintenance Texture properties of fish fillets, reduction of volatile base nitrogen accumulation, and effect of improving shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

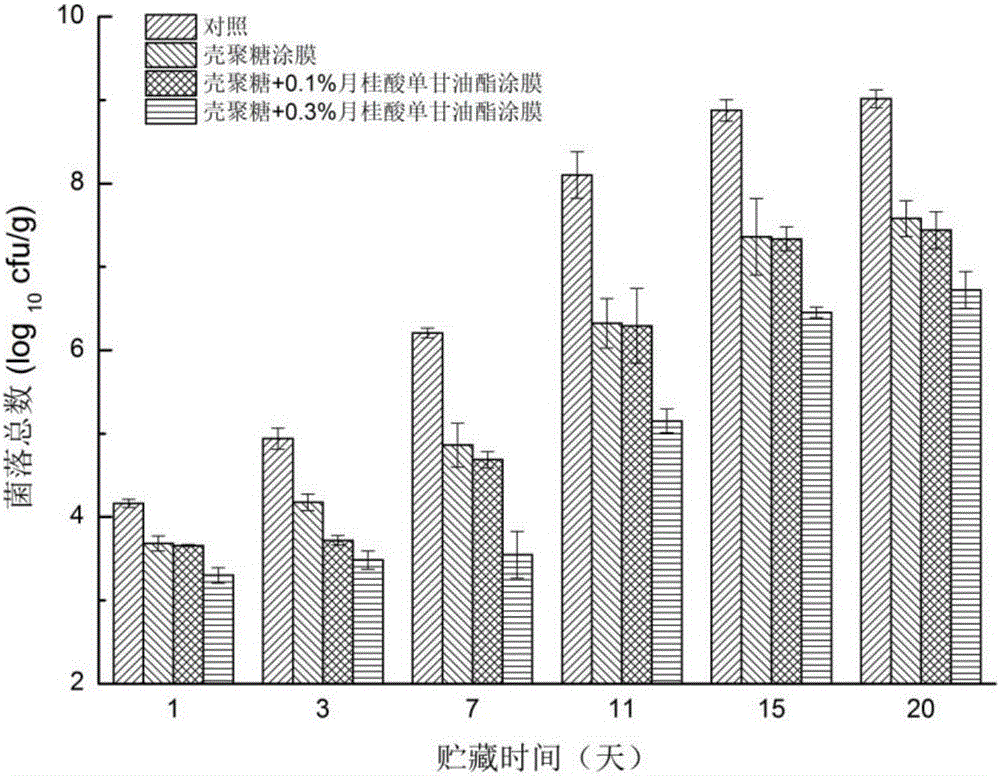

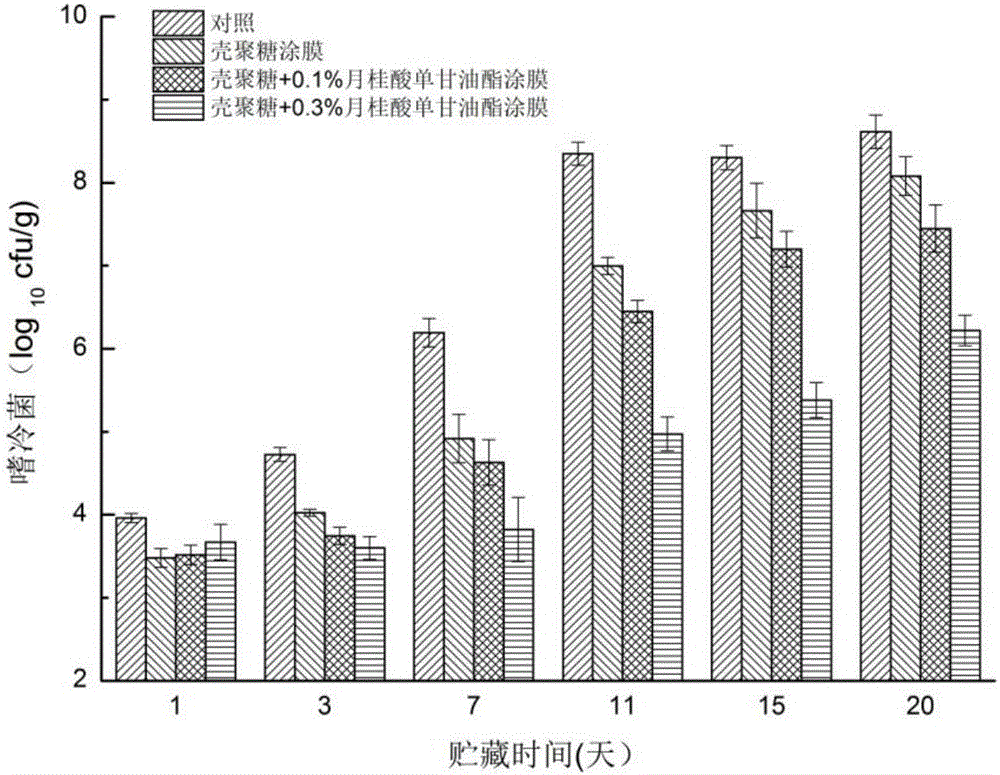

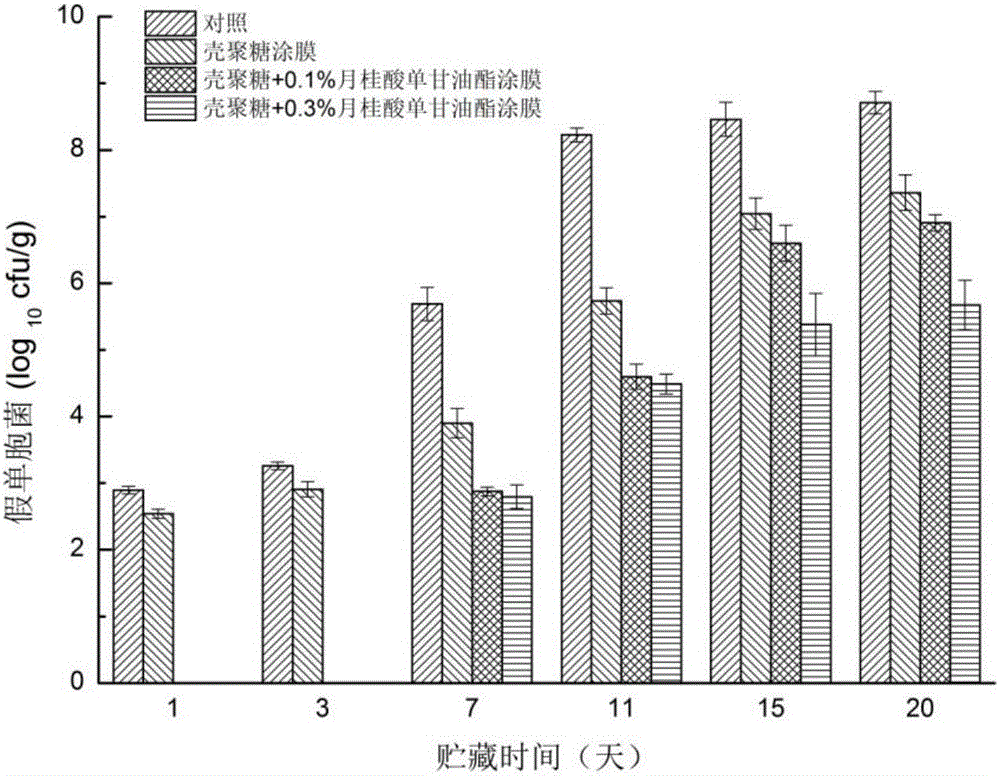

Examples

Embodiment 1

[0037] (1) Preparation of film preservative: take 10g chitosan (molecular weight: 400,000, degree of deacetylation: 75%), dissolve with 400mL of 1.25% acetic acid solution, stir for 4 hours at 25°C, and sonicate at 40KHz Degas for 30 minutes; add 2.5g of glycerin, continue to stir at 25°C for half an hour; then centrifuge at 10,000rpm at 4°C to remove insoluble matter to obtain a uniform chitosan solution, and finally adjust it to 500mL with deionized water to obtain a chitosan solution containing 2% chitosan Sugar coating solution.

[0038] (2) Slaughtering and slicing: kill fresh grass carp in ice water, kill and wash, cut the fish meat into fish fillets with a thickness of about 1.5cm; rinse the fish fillets in sterile water at 4°C for 15 seconds, take them out and drain them at 4°C .

[0039] (3) Coating treatment: immerse the drained fish fillets (about 400 g) in the coating preservative at 4°C for 5 minutes.

[0040] (4) Film-forming packaging: take out the fish fillet...

Embodiment 2

[0043] (1) Preparation of coating preservative: Weigh 10g chitosan (400,000 molecular weight, 85% degree of deacetylation), dissolve it with 400mL1.25% acetic acid solution, stir for 4 hours at 25°C, and ultrasonically remove it at 40KHz. Gas for 30min; add 2.5g of glycerin, and continue to stir for half an hour at 25°C; then centrifuge at 10,000rpm at 4°C to remove insoluble matter to obtain a uniform chitosan solution; : The ratio of 1:6:8 was stirred, and the microemulsion of monoglyceride laurate was obtained by ultrasonication at 40KHz for 1 hour; the microemulsion of monoglyceride laurate was added to the chitosan solution, and adjusted to 500mL with deionized water to obtain Contains 0.1% monoglyceride laurate ~ 2% chitosan coating liquid.

[0044] (2) Slaughtering and slicing: Fresh grass carp was killed in ice water, slaughtered and washed, and cut into fish fillets with a thickness of about 2 cm; the fish fillets were rinsed in sterile water at 4°C for 15 seconds, ta...

Embodiment 3

[0049] (1) Preparation of coating preservative: Weigh 10g chitosan (400,000 molecular weight, 85% degree of deacetylation), dissolve it with 400mL1.25% acetic acid solution, stir for 4 hours at 25°C, and ultrasonically remove it at 40KHz. Gas for 30min; add 2.5g of glycerin, and continue to stir for half an hour at 25°C; then centrifuge at 10,000rpm at 4°C to remove insoluble matter to obtain a uniform chitosan solution; : Stirring at a ratio of 1:6:8, ultrasonication at 40KHz for 1 hour to obtain monolaurin monoglyceride microemulsion; add monolaurate monoglyceride microemulsion to chitosan solution, adjust to 500mL with deionized water, antibacterial In the film preservative, the content of chitosan is 15g / L, and the content of lauric monoglyceride is 2g / L.

[0050] (2) Slaughtering and slicing: Fresh grass carp was killed in ice water, slaughtered and washed, and cut into fish fillets with a thickness of about 2 cm; the fish fillets were rinsed in sterile water at 4°C for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Shear force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com