A kind of preparation method and product and application of refrigerated freshwater fish fillet coating preservative

A technology of coating preservatives and freshwater fish fillets, which is applied in the direction of preserving meat/fish with coating protection layers, etc., which can solve the problems of high price of natural preservatives, impact on sensory quality of fish fillets, and increased production costs of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

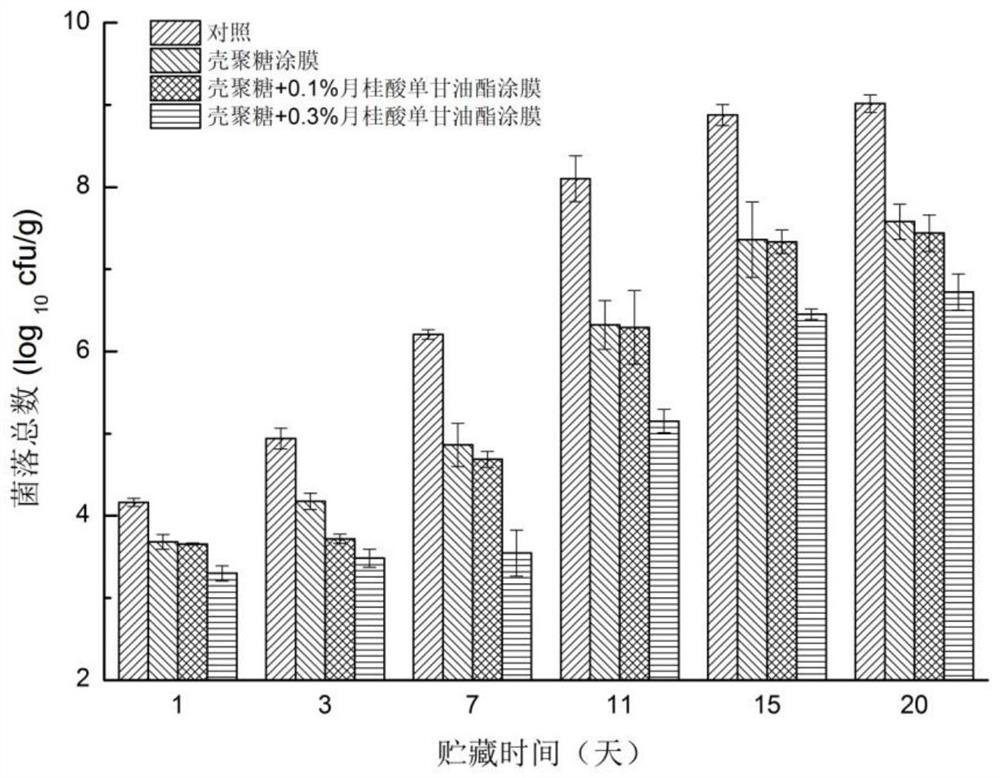

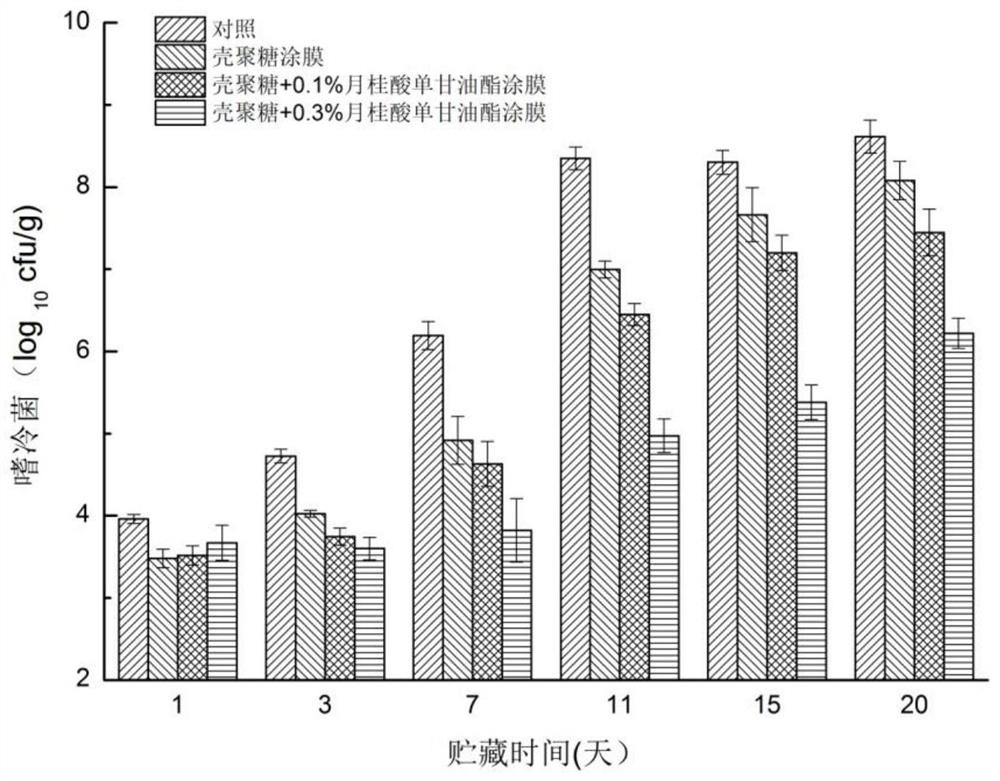

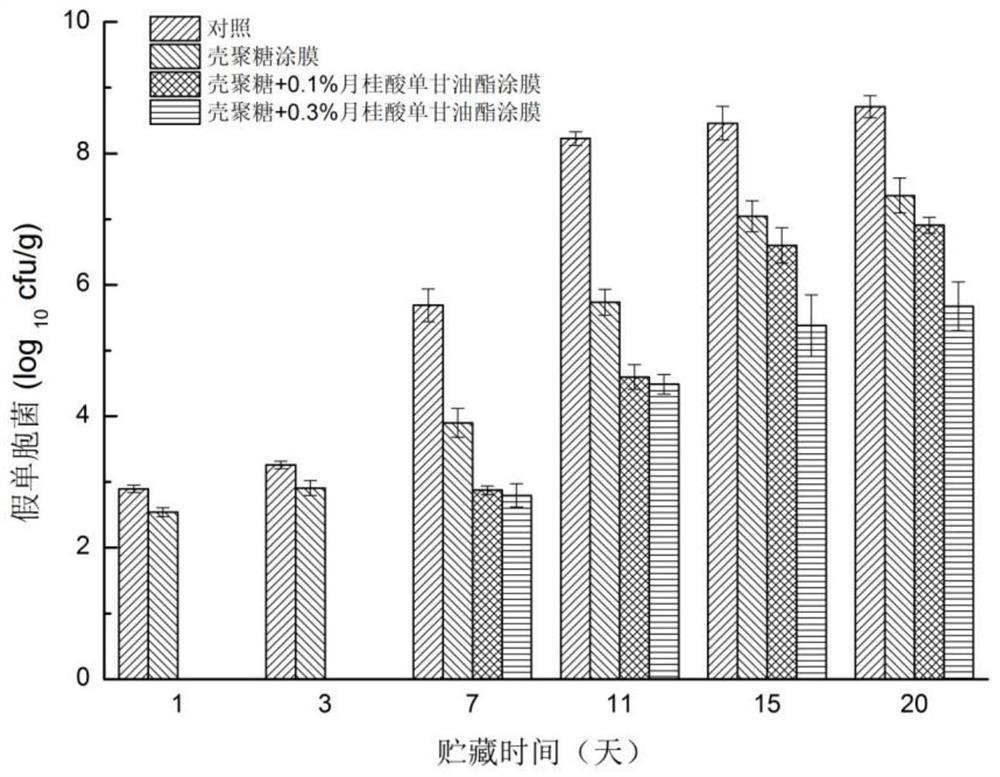

Embodiment 1

[0037] (1) Preparation of coating preservative: take 10g chitosan (molecular weight: 400,000, degree of deacetylation: 75%), dissolve with 400mL1.25% acetic acid solution, stir for 4 hours at 25°C, and ultrasonically at 40KHz Degas for 30 minutes; add 2.5g of glycerin, continue to stir at 25°C for half an hour; then centrifuge at 10,000rpm at 4°C to remove insoluble matter to obtain a uniform chitosan solution, and finally adjust it to 500mL with deionized water to obtain a chitosan solution containing 2% chitosan Sugar coating solution.

[0038] (2) Slaughtering and slicing: kill fresh grass carp in ice water, kill and wash, cut the fish meat into fish fillets with a thickness of about 1.5cm; rinse the fish fillets in sterile water at 4°C for 15 seconds, take them out and drain them at 4°C .

[0039] (3) Coating treatment: immerse the drained fish fillets (about 400 g) in the coating preservative at 4°C for 5 minutes.

[0040] (4) Film-forming packaging: take out the fish f...

Embodiment 2

[0043] (1) Preparation of coating preservative: Weigh 10g chitosan (400,000 molecular weight, 85% degree of deacetylation), dissolve it with 400mL1.25% acetic acid solution, stir for 4 hours at 25°C, and ultrasonically remove it at 40KHz. Gas for 30min; add 2.5g of glycerin, and continue to stir for half an hour at 25°C; then centrifuge at 10,000rpm at 4°C to remove insoluble matter to obtain a uniform chitosan solution; : The ratio of 1:6:8 was stirred, and the microemulsion of monoglyceride laurate was obtained by ultrasonication at 40KHz for 1 hour; the microemulsion of monoglyceride laurate was added to the chitosan solution, and adjusted to 500mL with deionized water to obtain Contains 0.1% monoglyceride laurate ~ 2% chitosan coating liquid.

[0044] (2) Slaughtering and slicing: Fresh grass carp was killed in ice water, slaughtered and washed, and cut into fish fillets with a thickness of about 2 cm; the fish fillets were rinsed in sterile water at 4°C for 15 seconds, ta...

Embodiment 3

[0049] (1) Preparation of coating preservative: Weigh 10g chitosan (400,000 molecular weight, 85% degree of deacetylation), dissolve it with 400mL1.25% acetic acid solution, stir for 4 hours at 25°C, and ultrasonically remove it at 40KHz. Gas for 30min; add 2.5g of glycerin, and continue to stir for half an hour at 25°C; then centrifuge at 10,000rpm at 4°C to remove insoluble matter to obtain a uniform chitosan solution; : Stirring at a ratio of 1:6:8, ultrasonication at 40KHz for 1 hour to obtain monolaurin monoglyceride microemulsion; add monolaurate monoglyceride microemulsion to chitosan solution, adjust to 500mL with deionized water, antibacterial In the film preservative, the content of chitosan is 15g / L, and the content of lauric monoglyceride is 2g / L.

[0050] (2) Slaughtering and slicing: Fresh grass carp was killed in ice water, slaughtered and washed, and cut into fish fillets with a thickness of about 2 cm; the fish fillets were rinsed in sterile water at 4°C for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com