Cocoa butter substitute prepared by camellia oil glycerolysis and preparation method thereof

A technology of cocoa butter and substitutes, which is applied in the field of cocoa butter substitutes and its preparation, can solve problems such as application limitations, and achieve the effects of inhibiting fat accumulation, high oleic acid content, and inhibiting the rise of cholesterol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

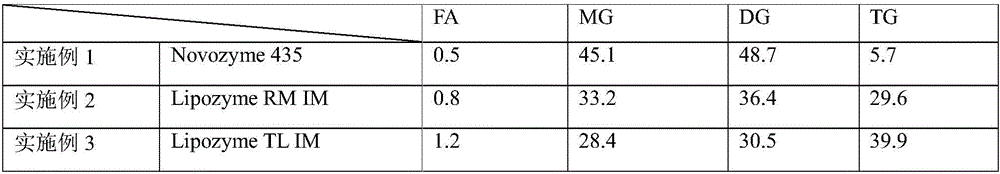

[0056] Embodiment 1-3 select enzyme

[0057] In this embodiment 1-3, Novozyme 435, Lipozyme RM IM, Lipozyme TL IM three kinds of enzymes catalyzed the properties of tea oil glycerol hydrolysis prepared by Danish company Novozymes were compared, and the molar ratio of triglyceride and glycerol in tea oil was taken = 1:1 amount mixed, adding the above-mentioned enzymes accounting for 5% of camellia oil mass ratio, and carrying out glycerolysis reaction at 60° C. for 36 hours. The composition of the initial product after glycerol hydrolysis was analyzed by TLC-FID. The results are shown in Table 1.

[0058] Table 1 (area ratio: %)

[0059]

[0060] FA: free fatty acid, MG: monoglyceride, DG: diglyceride, TG: triglyceride

[0061] The result of the reaction was that the activity of Novozyme 435 was higher than that of Lipozyme RM IM and Lipozyme TL IM. After 36 hours of reaction, the content of diglyceride in Novozyme 435 can reach 48.7%, while the residual amount of trigly...

Embodiment 4-7

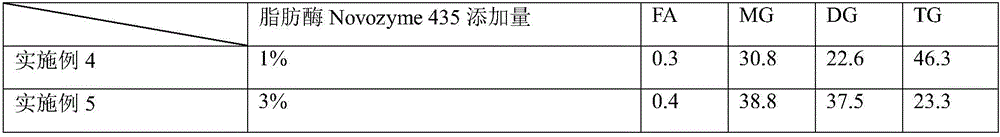

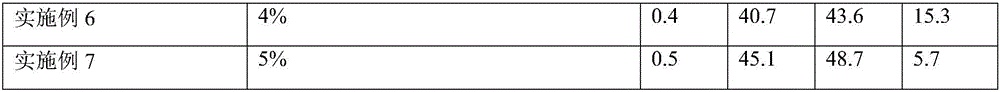

[0062] Example 4-7 Research on the reaction conditions of the glycerolysis of camellia oil catalyzed by Novozyme 435

[0063] In the present embodiment 4-7, the addition amount of lipase Novozyme 435 was investigated, and the amount of triglyceride and glycerin molar ratio = 1:1 in the camellia oil was mixed, and the addition accounted for 1-5% of the camellia oil mass ratio Glycolysis reaction was carried out at 60°C for 36 hours. The composition of the initial product after glycerol hydrolysis was analyzed by TLC-FID. The results are shown in Table 2.

[0064] Table 2

[0065]

[0066]

[0067] FA: free fatty acid, MG: monoglyceride, DG: diglyceride, TG: triglyceride

[0068] The above results found that the effect of glycerolysis was better when the amount of enzyme was 4-5%, and when the amount of enzyme in Example 7 was 5%, the composition in the crude product A of tea oil glycerolysis obtained by it was the best. More enzymes can also achieve the purpose of gly...

Embodiment 8

[0069] Example 8 Removal of Fatty Acids, Glycerol, Monoglycerides by Distillation

[0070] In Example 8, a molecular distillation device was used to remove unreacted glycerol and monoglycerides and fatty acids produced after the reaction from the reaction oil prepared by the enzymatic glycerolysis reaction. Distillation condition is vacuum degree 1×10 -3 mbar, 200°C, the mass content of diglyceride in the heavy phase after distillation is greater than 85%, the mass content of triglyceride is less than 10%, and the mass content of monoglyceride is less than 5%, which is recorded as product B after molecular distillation. And the mass ratio of monoglyceride to diglyceride in the distilled light phase is greater than 10:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com