A kind of Suaeda salsa seed carotenoid extraction process

An extraction process, the technology of Suaeda salsa, applied in the field of plant extraction, achieves the effect of fast and effective extraction method, strong operability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A process for extracting carotenoids from Suaeda salsa seeds, comprising the following steps:

[0027] 1) Weigh 0.1 g of Suaeda salsa seeds respectively, and grind them fully in a mortar under liquid nitrogen.

[0028] 2) Determine the ratio of the extractant as petroleum ether: acetone = 1:1.

[0029] 3) Add 5 mL of extraction agent (petroleum ether: acetone volume ratio = 2:1), so that the solid-liquid ratio is 1:50.

[0030] 4) Ultrasonic extraction is performed for 10 minutes each time, the ultrasonic frequency is 600 W, and the ultrasonic temperature is 30 °C.

[0031] 5) Ultrasonic extraction is performed twice, and the ratio of material to liquid is controlled to be 1:50 for each ultrasonic extraction (after the first ultrasonic extraction, filter, and the obtained residue is subjected to the second ultrasonic extraction).

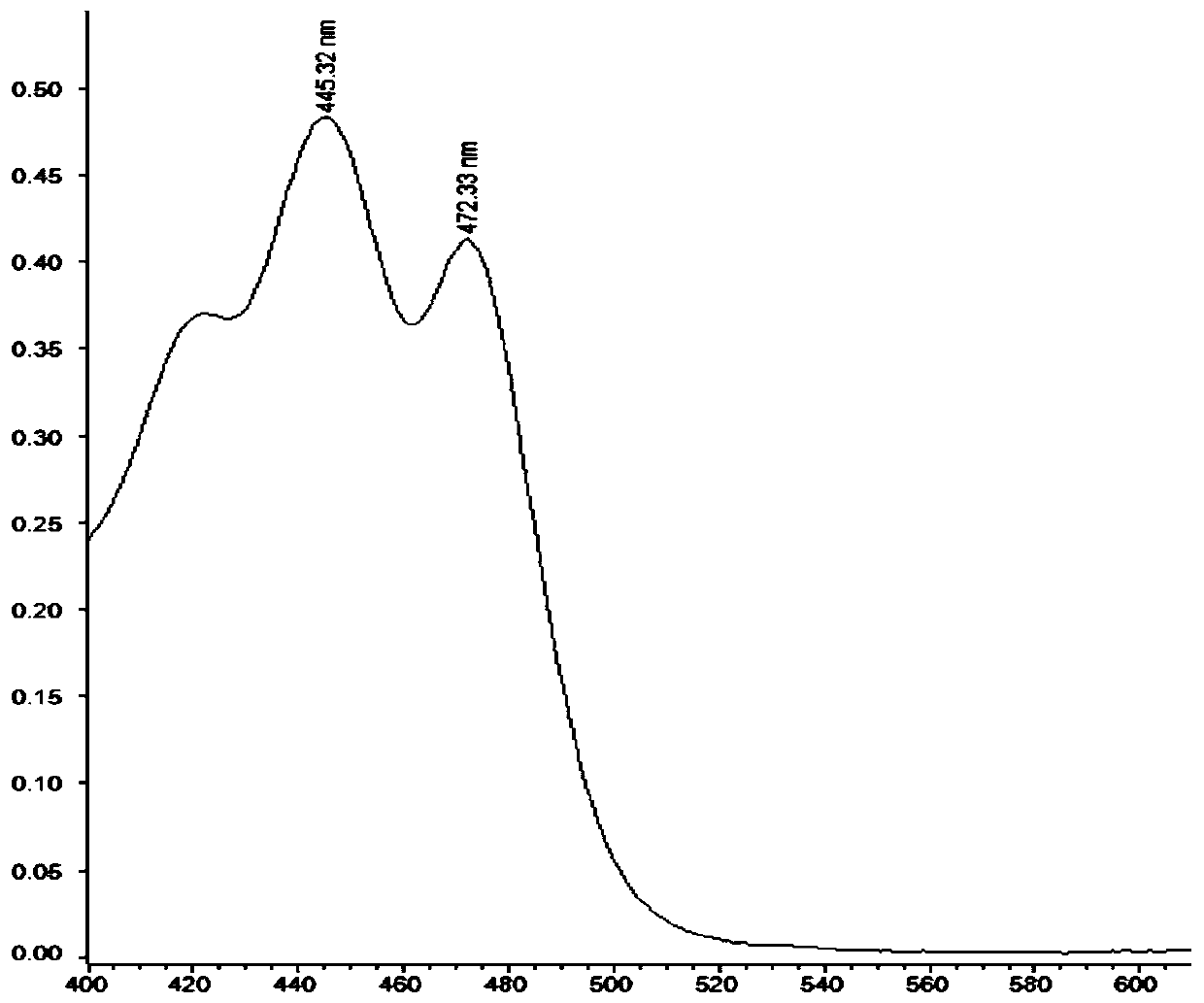

[0032] 6) Combine the extracts, centrifuge at 5000 rpm for 5 min, take the supernatant and dry it with nitrogen to obtain the Suaeda salsa...

Embodiment 2

[0034] A process for extracting carotenoids from Suaeda salsa seeds, comprising the following steps:

[0035] 1) Weigh 0.1 g of Suaeda salsa seeds respectively, and grind them fully in a mortar under liquid nitrogen.

[0036] 2) Determine the ratio of the extractant as petroleum ether: acetone = 1:1.

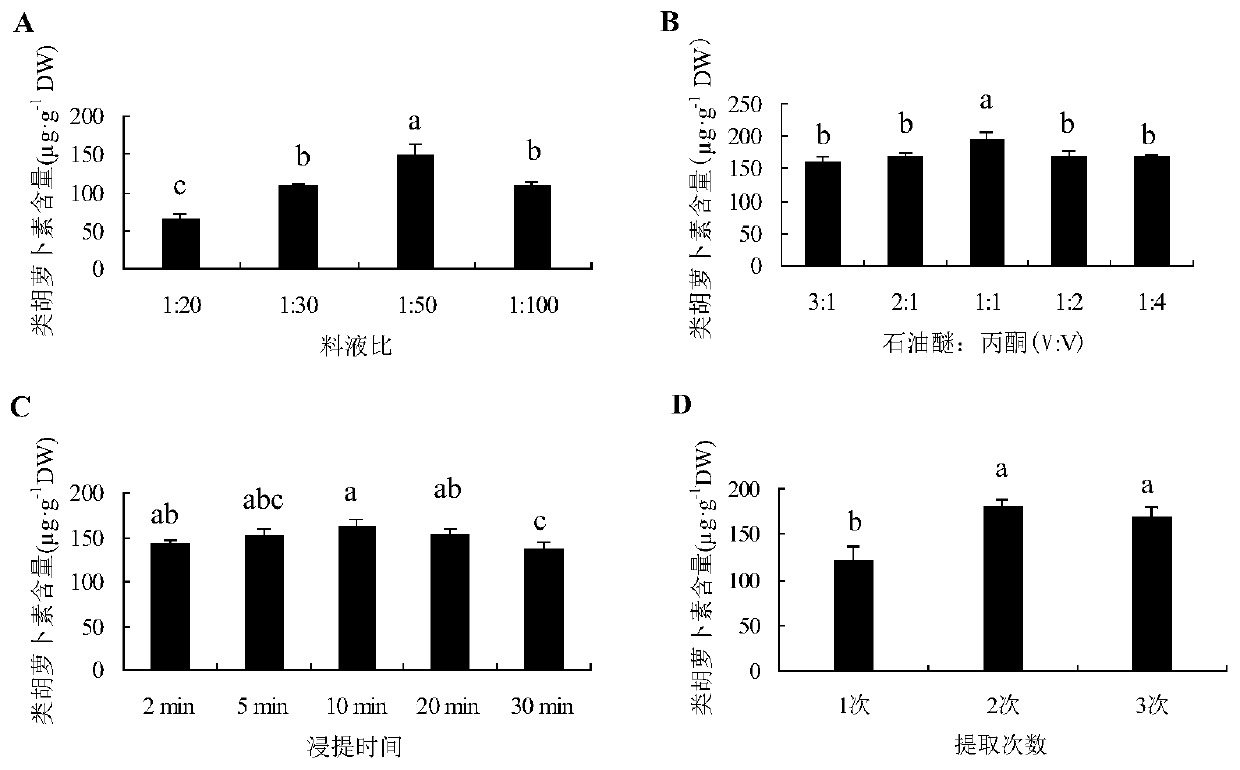

[0037] 3) Add 2, 3, 5 and 10 mL of extraction agent (petroleum ether: acetone volume ratio = 1:1) respectively, so that the solid-liquid ratio is 1:20, 1:30, 1:50, 1:100.

[0038]4) Ultrasonic extraction was performed for 8 minutes each time, the ultrasonic frequency was 580 W, and the ultrasonic temperature was 35 °C.

[0039] 5) Ultrasonic extraction is performed twice, and the ratio of solid to liquid is controlled to be 1:50 for each ultrasonic extraction.

[0040] 6) Combine the extracts, centrifuge at 5000 rpm for 5 min, take the supernatant and dry it with nitrogen to obtain the Suaeda salsa seed carotenoids. Then the volume was adjusted to 3 mL with acetone, and the l...

Embodiment 3

[0043] A process for extracting carotenoids from Suaeda salsa seeds, comprising the following steps:

[0044] 1) Weigh 0.1 g of Suaeda salsa seeds respectively, and grind them fully in a mortar under liquid nitrogen.

[0045] 2) Determine the ratio of the extraction agent as petroleum ether: acetone = 3:1, 2:1, 1:1, 1:2 and 1:4.

[0046] 3) Add 5 mL of extraction agent (petroleum ether: acetone volume ratios are 3:1, 2:1, 1:1, 1:2 and 1:4 respectively) to make the solid-liquid ratio 1:50.

[0047] 4) Ultrasonic extraction is performed for 8 minutes each time, the ultrasonic frequency is 580 W, and the ultrasonic temperature is 30 °C.

[0048] 5) Ultrasonic extraction is performed twice, and the ratio of solid to liquid is controlled to be 1:50 for each ultrasonic extraction.

[0049] 6) Combine the extracts, centrifuge at 5000 rpm for 5 min, take the supernatant and dry it with nitrogen to obtain the Suaeda salsa seed carotenoids. Then the volume was adjusted to 3 mL with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com