Water-extraction preparation method and application of antibacterial active component in bamboo willow

An antibacterial activity and water extraction technology is applied in the field of water extraction and preparation of antibacterial active components of bamboo and willow. , the effect of increasing the added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of bamboo willow antibacterial active component comprises the following steps:

[0031] A) Extraction: Precisely weigh 100g of bamboo willow bark powder that has been crushed and passed through a 24-mesh sieve, add ten times the amount of distilled water, and perform ultrasonic extraction for 3 times, each time for 90 minutes, with an ultrasonic frequency of 18KHz and an ultrasonic temperature of 50°C, suction filtration, and extraction Liquid merge;

[0032] B) Alcohol precipitation: the extract is concentrated under reduced pressure to 50 mL, slowly add 140 mL of 95% ethanol to make the alcohol content of the extract reach 70%, store at 4°C for 18 hours, centrifuge, take the supernatant, and concentrate under reduced pressure to no alcohol taste;

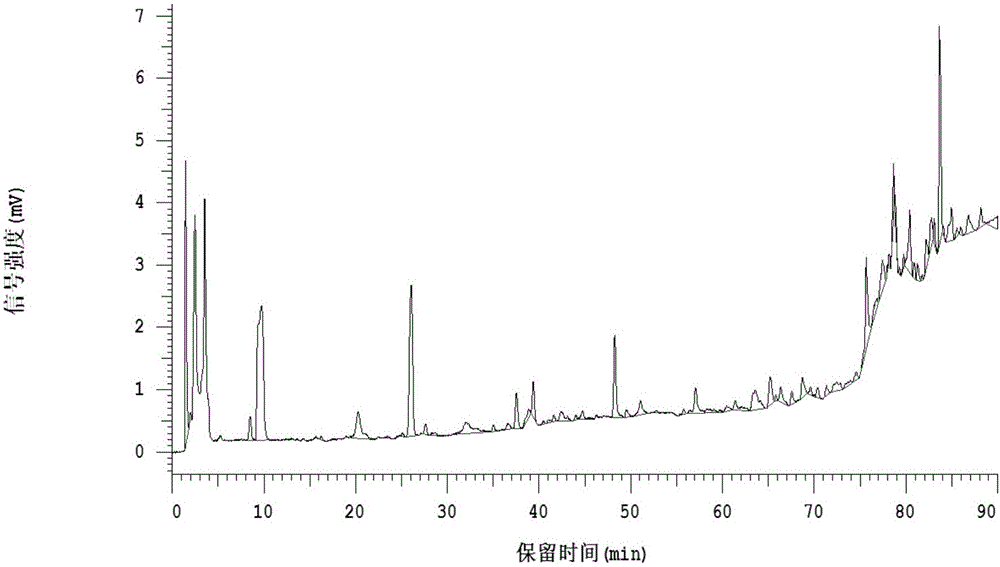

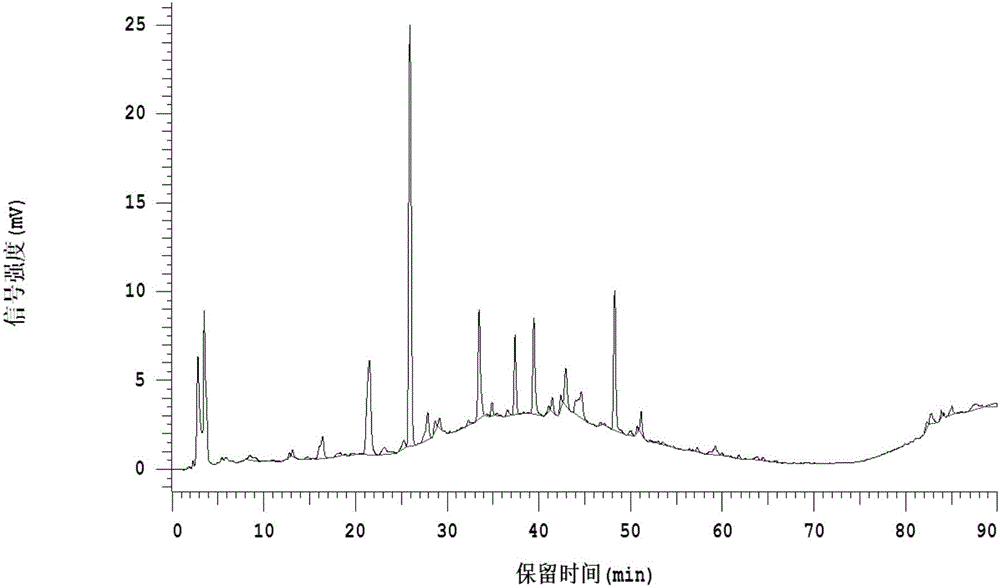

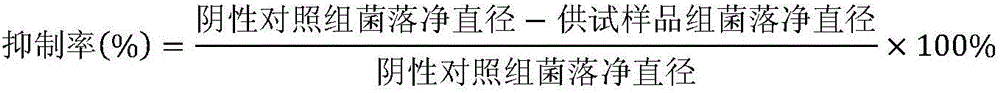

[0033] C) Separation of macroporous resin: AB-8 type macroporous resin wet-packed column, diameter-to-height ratio 1:12, step B) obtained concentrated solution wet loading, with distilled water, volume frac...

Embodiment 2

[0037] The preparation of bamboo willow antibacterial active component comprises the following steps:

[0038] A) Extraction: Accurately weigh 100g of bamboo willow skin powder that has been crushed and passed through a 40-mesh sieve, add 5 times the amount of distilled water, and perform ultrasonic extraction for 3 times, 60 minutes each time, with an ultrasonic frequency of 12KHz and an ultrasonic temperature of 55°C, suction filtration, and extraction Liquid merge;

[0039] B) Alcohol precipitation: the extract is concentrated under reduced pressure to 50 mL, slowly add 120 mL of 95% ethanol to make the alcohol content of the extract reach 60%, store at 4°C for 24 hours, centrifuge, take the supernatant, and concentrate under reduced pressure to no alcohol taste;

[0040] C) Separation of macroporous resin: AB-8 type macroporous resin wet-packed column, diameter-to-height ratio 1:12, step B) obtained concentrated solution wet loading, with distilled water, volume fraction ...

Embodiment 3

[0044] The preparation of bamboo willow antibacterial active component comprises the following steps:

[0045] A) Extraction: Accurately weigh 100g of bamboo willow bark powder that has been crushed and passed through a 10-mesh sieve, add 20 times the amount of distilled water, perform ultrasonic extraction 4 times, each time 90min, ultrasonic frequency 9KHz, ultrasonic temperature 70°C, suction filtration, extraction Liquid merge;

[0046] B) Alcohol precipitation: the extract is concentrated under reduced pressure to 50mL, slowly add 160mL of 95% ethanol to make the alcohol content of the extract reach 80%, store at 4°C for 12h, centrifuge, take the supernatant, and concentrate under reduced pressure to no alcohol taste;

[0047] C) Separation of macroporous resin: AB-8 type macroporous resin wet-packed column, diameter-to-height ratio 1:12, step B) obtained concentrated solution wet loading, with distilled water, volume fraction 30%, 50% and 95% ethanol solution as the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com