Gradient pore diameter filtering membrane and preparation method and application thereof

A technology of filtration membrane and pore size, applied in the direction of filtration accessories, instruments introduced into the body, etc., can solve the problems of filtration effect and general stagnation effect, etc., and achieve the effect of increasing the safety and convenience of use, and the safety and convenience of the infusion process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

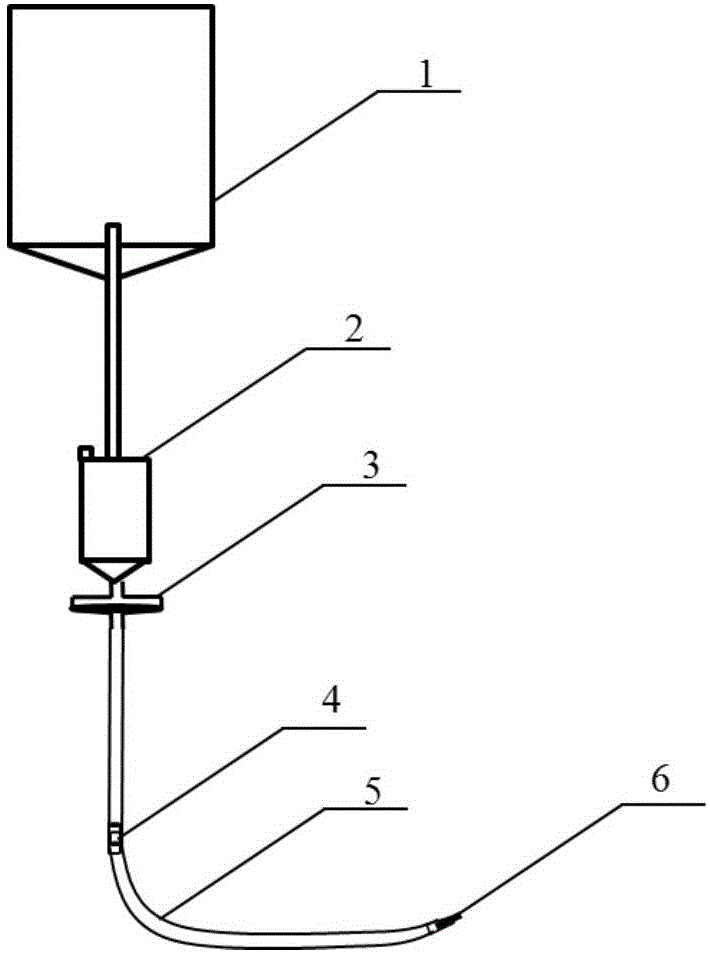

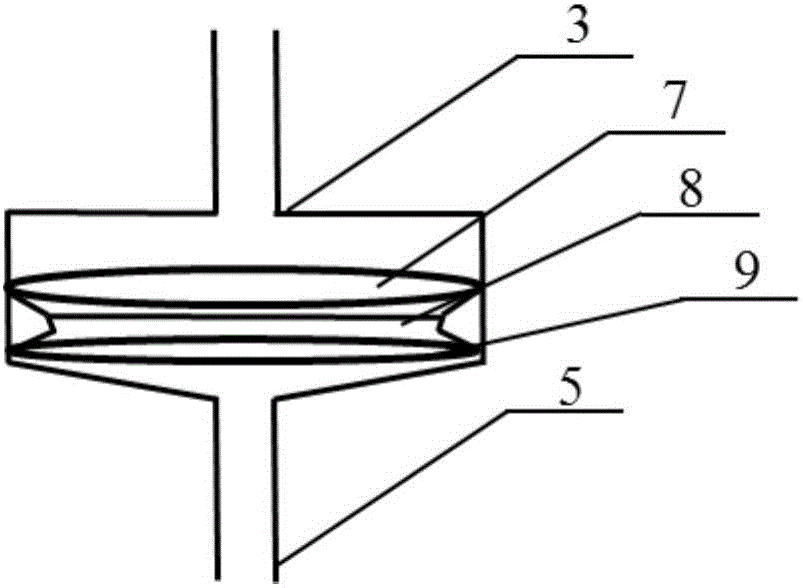

[0030] Embodiment 1: Polycaprolactone (PCL) prepares gradient pore size filter membrane

[0031] Select polycaprolactone (PCL) dissolved in hexafluoroisopropanol (HFIP) 8wt% as the spinning solution, rationally design and prepare three-layer gradient pore size filter membrane, prepare the filter membrane after near-field electrospinning, and the moving speed range of the receiving plate 20 ~ 100mm / s, take it off and dry it in vacuum at 60°C. The prepared gradient pore size filter membrane, the upper and lower layers have a pore size of 5-7 μm, the middle layer is 0.5-2 μm, the thickness of the upper and lower layers of the filter membrane is 0.3 mm, the middle layer is 0.4 mm, and the overall thickness is about 1.0 mm. The liquid-stop filter tank forms an automatic liquid-stop device for the actual test of physiological saline infusion.

[0032] After testing, the gradient aperture filter membrane prepared by the polycaprolactone has a good filtering effect on particulates du...

Embodiment 2

[0033] Embodiment 2: Polylactic acid (PLA) prepares gradient aperture filter membrane

[0034] Select polylactic acid (PLA) dissolved in dichloromethane 10wt% as the spinning solution, rationally design and prepare three-layer gradient pore size filter membrane, prepare the filter membrane after near-field electrospinning, the moving speed range of the receiving plate is 50-100mm / s, take After vacuum drying at 60°C, a gradient pore size filter membrane is prepared. The pore size of the upper and lower layers is 6-8 μm, and the middle layer is 0.5-1.5 μm. The thickness of the upper and lower layers of the membrane is 0.25 mm, and the middle layer is 0.6 mm. The overall thickness About 1.1mm, it is installed into the liquid stop filter tank to form an automatic liquid stop device for intravenous infusion of glucose medicine.

[0035] After testing, the gradient pore size filter membrane prepared by the polylactic acid has a good filtering effect on particulates during infusion, ...

Embodiment 3

[0036] Embodiment 3: Polylactic acid-glycolic acid copolymer (PLGA) prepares gradient pore size filter membrane

[0037] Select polylactic acid-glycolic acid copolymer (PLGA) dissolved in 12wt% chloroform as the spinning solution, rationally design and prepare three-layer gradient pore size filter membrane, prepare the filter membrane after near-field electrospinning, and the moving speed range of the receiving plate is 100-200mm / s, take it off and dry it under vacuum at 60°C. The prepared gradient pore size filter membrane, the upper and lower layers have a pore size of 6-8 μm, the middle layer is 0.5-2.0 μm, the thickness of the upper and lower layers of the filter membrane is 0.3 mm, the middle layer is 0.6 mm, and the overall thickness is about 1.2 mm. An automatic liquid stop device is installed in the liquid stop filter tank for intravenous infusion and delivery of glucose medicine solution.

[0038] After testing, the gradient pore size filter membrane prepared by the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com