Method for preparing binary denitration sulfur-resistant catalyst-loaded filter material by using one-step in-situ synthesis method

An in-situ synthesis and catalyst technology, applied in the direction of organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve good sulfur resistance, fast reaction, uniform loading capacity and firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

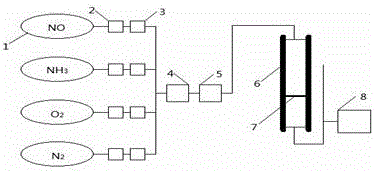

Method used

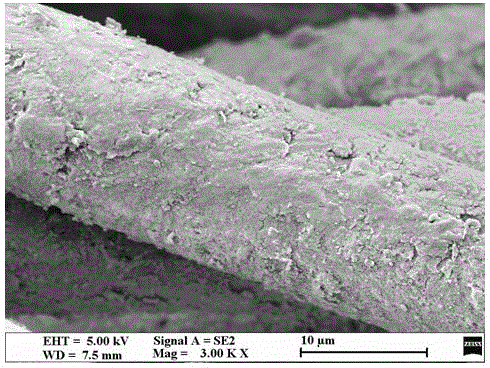

Image

Examples

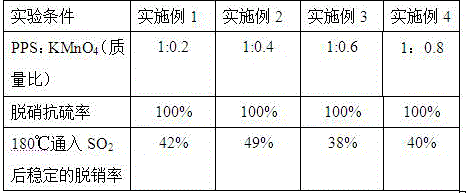

Embodiment 1

[0029] First weigh 32ml of concentrated nitric acid and add it to 68ml of deionized water to make a 30% dilute nitric acid solution. Then put in 0.753g of PPS and treat it in a water bath at 80°C for 1 hour. After the treatment, wash the PPS with deionized water and ethanol until it is neutral (PH=6~7), and put it in a vacuum drying oven at about 100°C Dry for 1-2h, and dry for later use.

[0030] Add 0.3545 g of cerium trichloride heptahydrate into a beaker with 50 ml of deionized water, stir well, then ultrasonically or shake the solution until the solute is completely dissolved; then add PPS to the cerium chloride solution, and then place it at room temperature Stir for 12 hours until enough Ce is adsorbed on the surface of PPS 2+ After the cations are removed, move them into a water bath, and then configure a potassium permanganate solution with a concentration of 0.02M (according to the mass ratio, polyphenylene sulfide: potassium permanganate = 1:0.2), and slowly dissol...

Embodiment 2

[0033] First weigh 32ml of concentrated nitric acid and add it to 68ml of deionized water to make a 30% dilute nitric acid solution. Then put in 0.6249gPPS and treat it in a water bath at 80°C for 1h. After the treatment, wash the PPS with deionized water and ethanol until it is neutral (PH=6~7), and dry it in a vacuum oven at about 100°C for 1 hour. -2h, dry for later use.

[0034] Add 0.5886g of cerium trichloride heptahydrate into a beaker with 50ml of deionized water, stir evenly, then ultrasonically or shake the prepared solution until the solute is completely dissolved; then add PPS to the cerium chloride solution, and then place it at room temperature Stir for 12 hours until enough Ce is adsorbed on the surface of PPS 2+After the cations are removed, move them into a water bath, and then configure a potassium permanganate solution with a concentration of 0.03M (according to the mass ratio, polyphenylene sulfide: potassium permanganate = 1:0.4), and slowly dissolve the ...

Embodiment 3

[0037] First weigh 32ml of concentrated nitric acid and add it to 68ml of deionized water to make a 30% dilute nitric acid solution. Then put in 0.6830gPPS and treat it in a water bath at 80°C for 1h. After the treatment, wash the PPS with deionized water and ethanol until it is neutral (PH=6~7), and dry it in a vacuum drying oven at about 100°C for 1 hour. -2h, dry for later use.

[0038] Add 0.90416g of cerium chloride trihydrate heptahydrate into a beaker with 50ml of deionized water, stir evenly, then ultrasonically or shake the solution until the solute is completely dissolved; then add PPS to the cerium chloride solution, and then place it at room temperature Stir for 12 hours until enough Ce is adsorbed on the surface of PPS 2+ After the cations are removed, move them into a water bath, and at this time configure a potassium permanganate solution with a concentration of 0.05M (according to the mass ratio, polyphenylene sulfide: potassium permanganate = 1:0.6), and slow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com