Carbon anode roasting fume purification ultra-low emission system and process

A technology for flue gas purification and carbon anode, which is used in gas treatment, chemical instruments and methods, combined devices, etc., can solve the problems of difficulty in releasing electric charges, waste of energy, deterioration of purification performance, etc., to increase the specific dust collection area, improve Purification efficiency, the effect of increasing corona density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

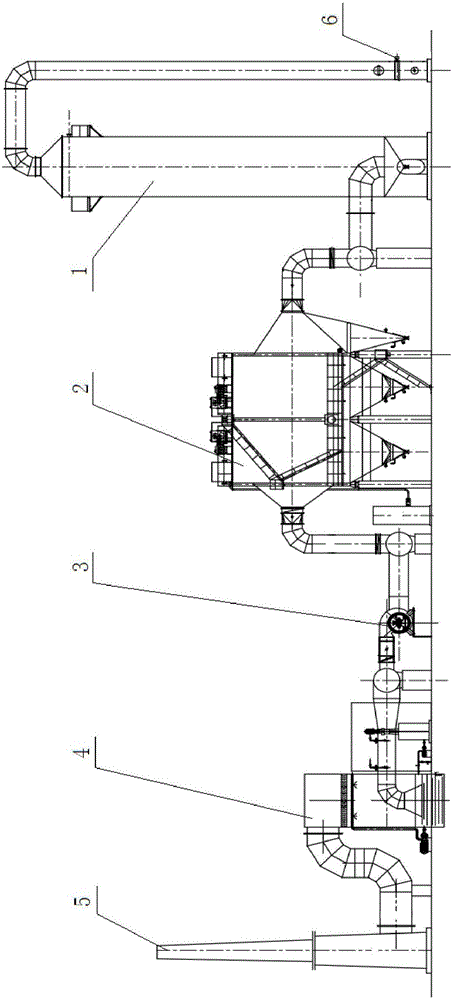

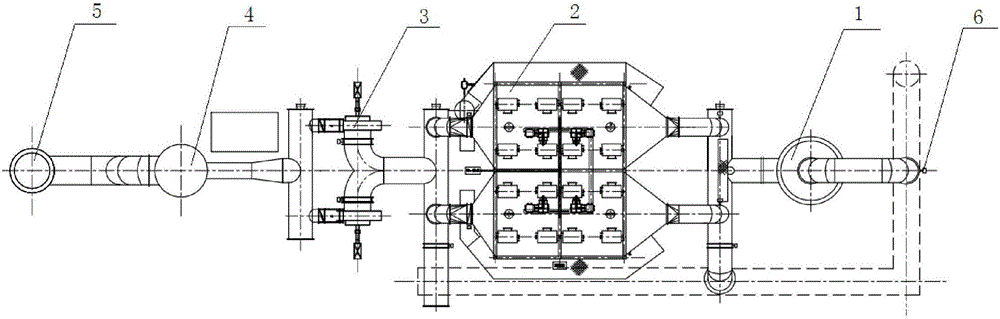

[0050] See Figure 1-Figure 2 , a carbon anode roasting flue gas purification ultra-low emission system, including a spray cooler 1, an electric tar catcher 2, a desulfurization and defluorination device 4, and the flue gas output end of the spray cooler 1 is connected to the electric tar catcher 2 The flue gas inlet of the electric tar catcher 2 is connected to the flue gas inlet of the desulfurization and defluorination device 4 through the exhaust fan 3, and the flue gas outlet of the desulfurization and defluorination device 4 is connected to the chimney 5; the electric tar catcher 2 The anode system in the system adopts a combined multi-functional bimodal plate anode row, and the cathode system adopts prismatic lines and square lines; a hot water cleaning device is installed on the electric tar catcher 2 .

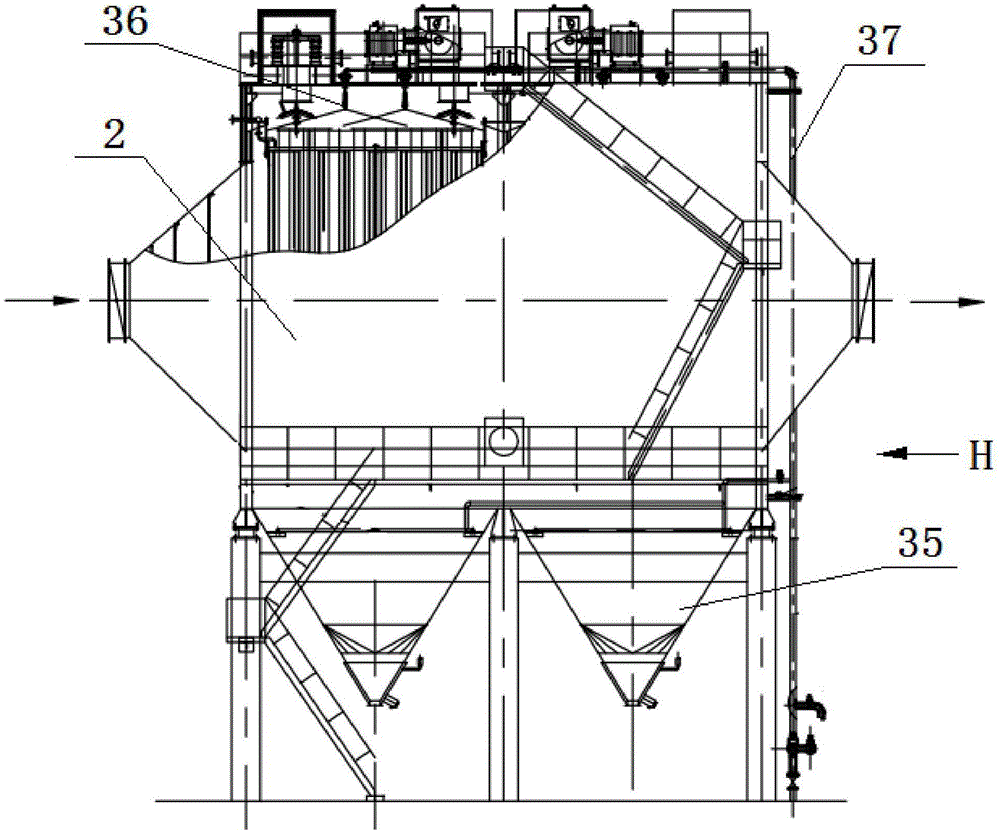

[0051] See image 3 , Figure 4 , Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com