Plate type membrane module

A plate-type membrane and component technology, applied in the field of filtration, can solve the problems of increasing production costs, reducing product quality, and non-machining, etc., and achieves the effects of improving the stability of use, simple disassembly and installation, and high effective filtration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

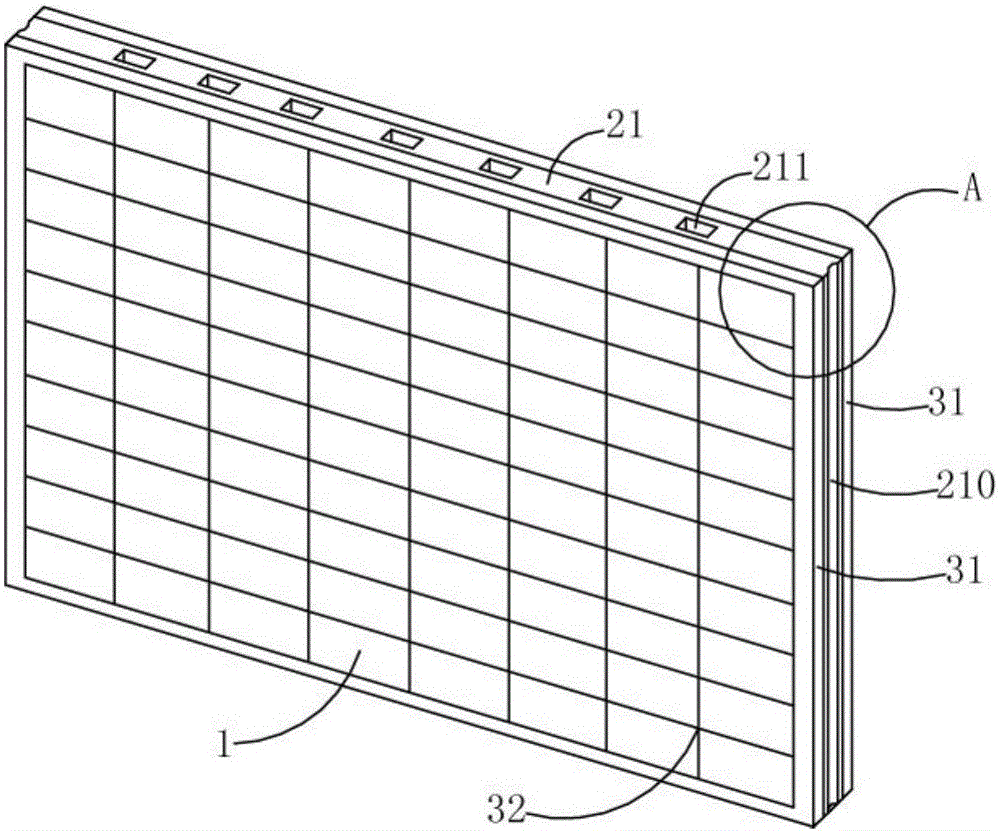

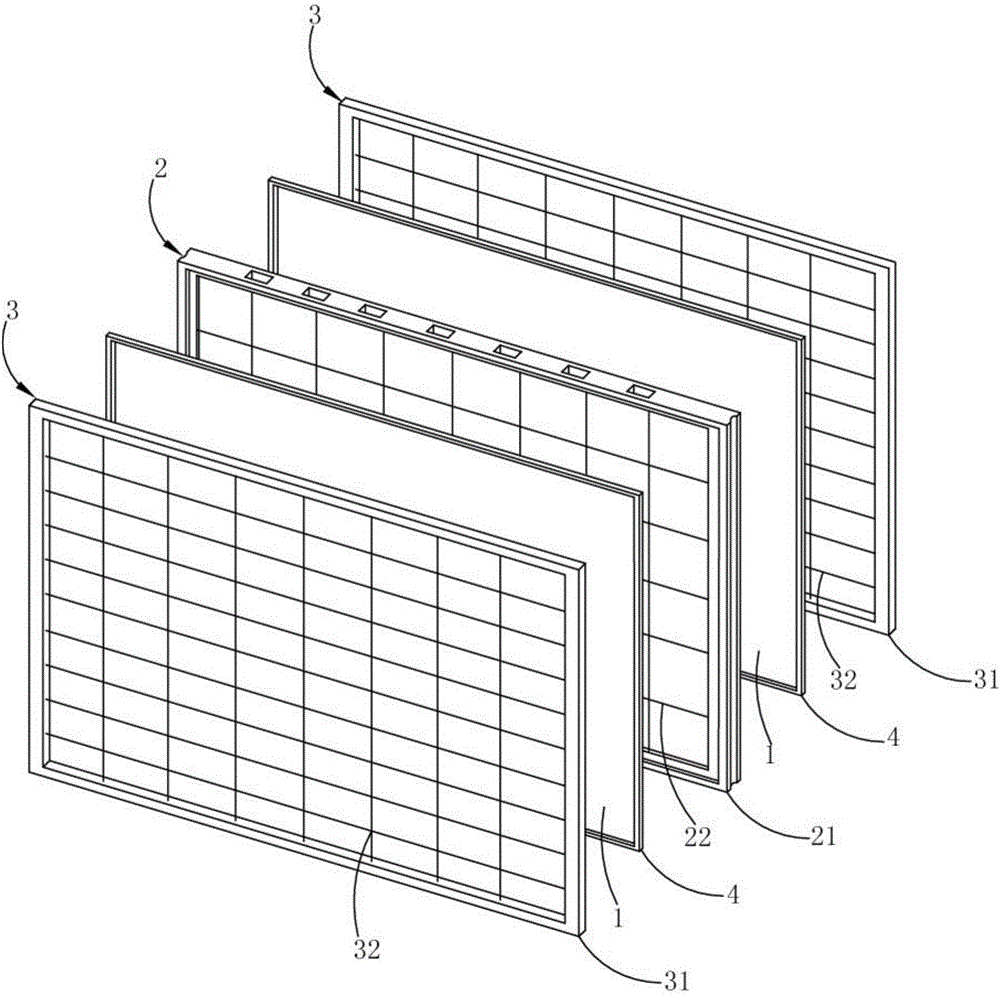

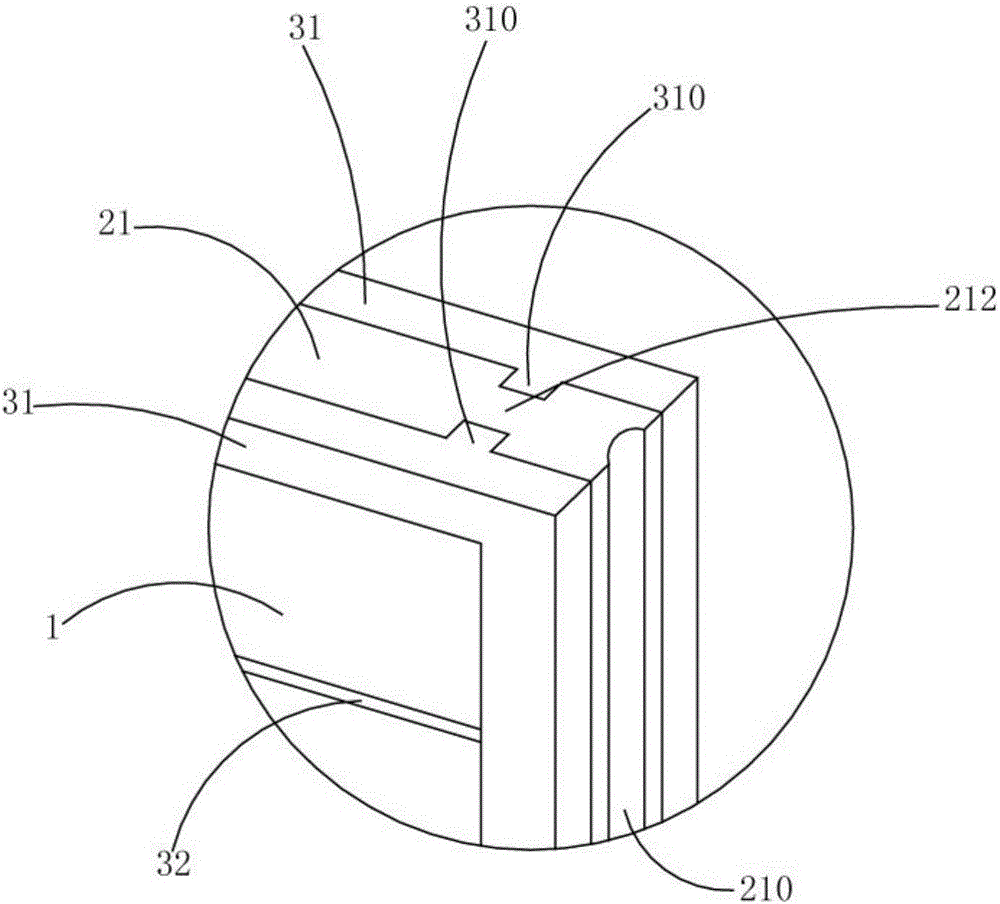

[0029] Such as figure 1 with figure 2 The illustrated plate membrane module with a rectangular shape includes two opposing diaphragms 1, an inner support 2 located between the two diaphragms 1, two outer supports 3, the inner support 2 includes The first frame body 21, the first net body 22 that crosses each side of the first frame body 21 facing each other inwardly, the two diaphragms 1 and the first frame body 21 are hermetically connected and are respectively located in the first net body 21 on both sides; the outer support body 3 includes a second frame 31, a second net 32 straddling each side of the second frame 31 facing each other, the second frame 31 and the first The frame 21 is firmly connected and the diaphragm 1 is located between the first mesh body 22 and the second mesh body 32; each of the two long sides of the first frame body 21 is provided with 7 equidistantly distributed At the liquid outlet 211, the clear liquid formed after the original liquid passes th...

Embodiment 2

[0033] The flat membrane module of this embodiment is on the basis of embodiment 1, and further the second mesh body 32 is provided on the side opposite to the diaphragm 1 with a height of 5mm and a diameter of 5mm perpendicular to the diaphragm 1. The cylindrical support column 5 enables the diaphragm 1 to be clamped between the support column 5 of the first mesh body 22 and the support column 5 of the second mesh body 32.

Embodiment 3

[0035] Such as Figure 4 As shown, the flat membrane module of this embodiment is on the basis of embodiment 1 or 2, and further is provided with a vertical on both sides of the first mesh body 22 and the two sides of the second mesh body 32. A cylindrical support column 5 with a height of 5 mm and a diameter of 5 mm on the diaphragm 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com