Method for preparing cube-shaped silver nano box with octreotide acetate as template

An octreotide acetate and silver nanotechnology, applied in the field of materials, can solve the problems of high cost, potential environmental and biological hazards, complex preparation process and the like, and achieve the effects of regular morphology, good binding condition and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

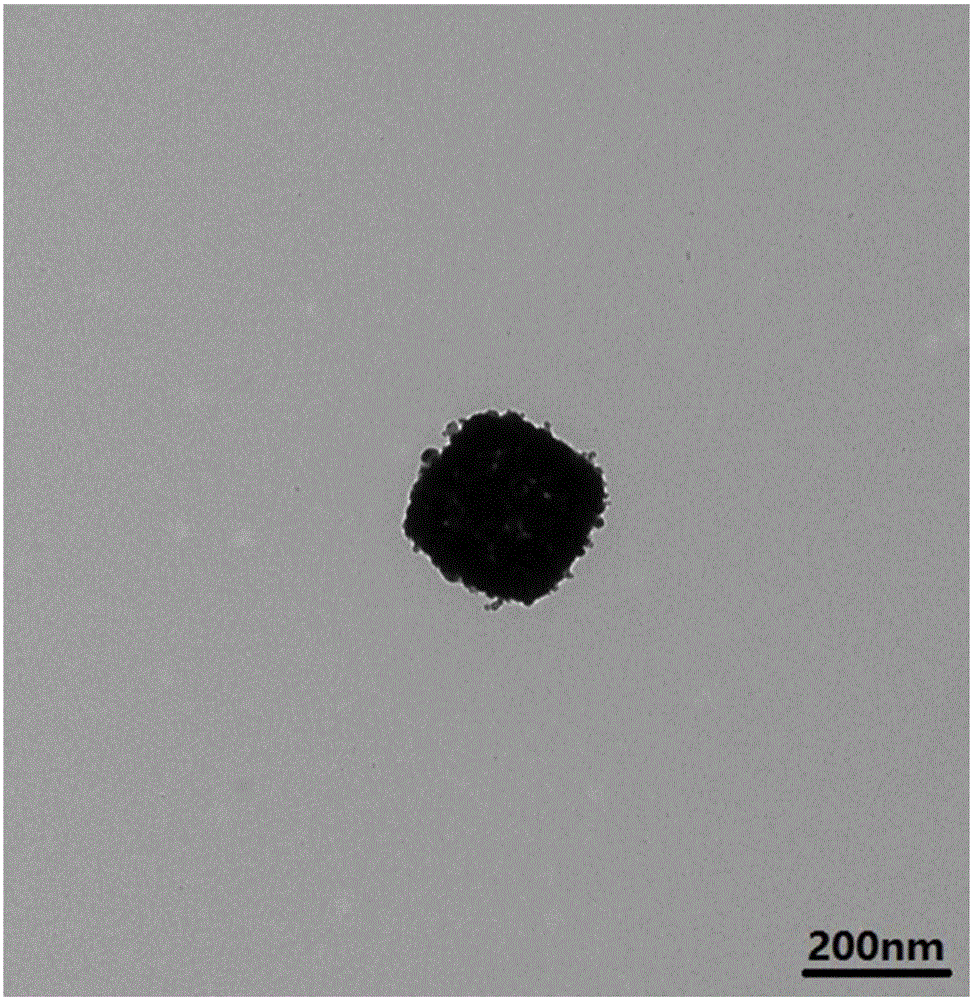

Embodiment 1

[0022] Dissolve octreotide acetate (Shanghai Taishi Biotechnology Co., Ltd.) in hydrochloric acid (Yongfei Chemical Factory) solution to prepare octreotide acetate solution with a concentration of 0.1mM and a pH value of 3, and then place it in a constant temperature metal bath at 60°C 30min;

[0023] Prepare AgNO at a concentration of 0.9mM 3 (Beijing Beihua Fine Chemicals Co., Ltd.) solution and ascorbic acid (Beijing Baierdi Biotechnology Co., Ltd.) solution with a mass concentration of 3%, they were mixed with a volume ratio of 1:1, and ultrasonic treatment was performed for 30 s, and the ultrasonic power was 90W, to obtain silver colloidal solution;

[0024] Prepare AgNO at a concentration of 7mM 3 (Beijing Beihua Fine Chemicals Co., Ltd.) solution, mixed with the above-mentioned octreotide acetate solution and silver colloid solution at a volume ratio of 1:1:3, placed in a digital display double-layer air bath constant temperature oscillator, at 200rpm., Incubate at 1...

Embodiment 2

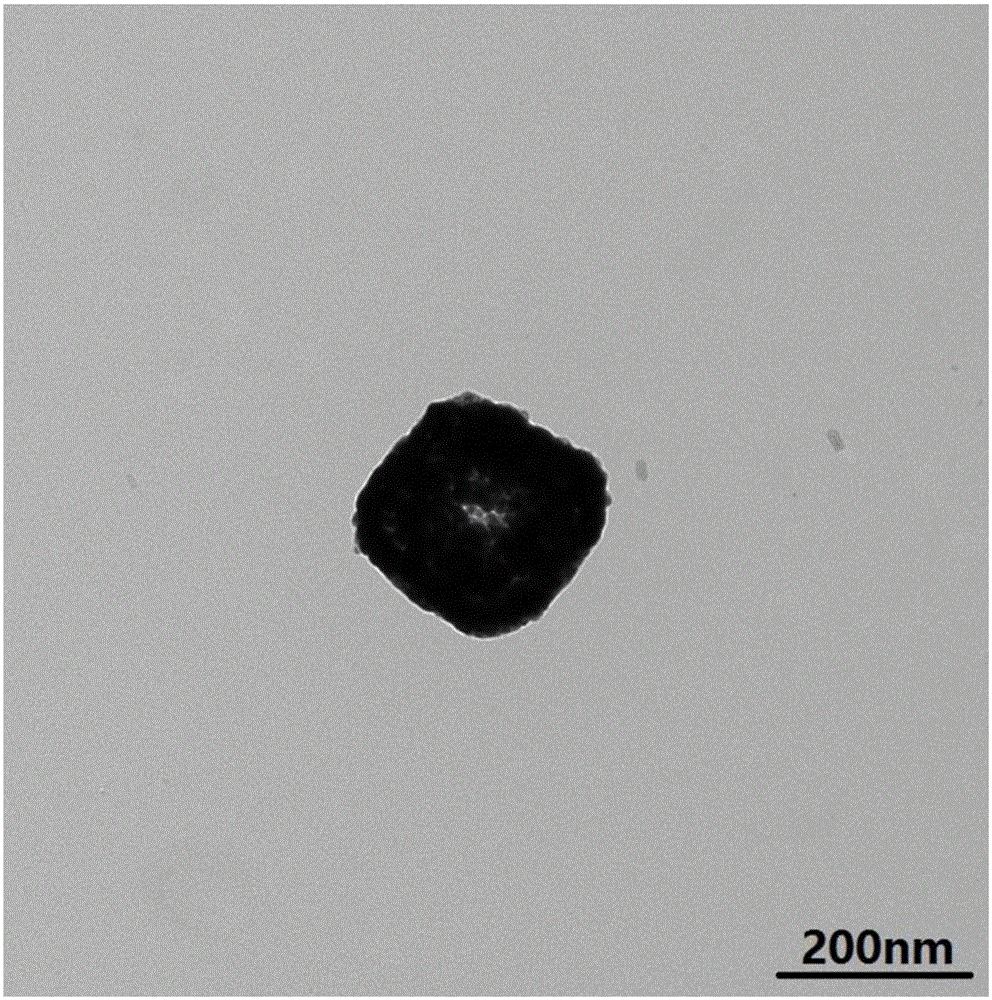

[0028] Dissolve octreotide acetate (Shanghai Taishi Biotechnology Co., Ltd.) in hydrochloric acid (Yongfei Chemical Factory) solution to prepare an octreotide acetate solution with a concentration of 0.2mM and a pH value of 2, and then place it in a constant temperature metal bath at 70°C 20min;

[0029] Prepare AgNO at a concentration of 1.1mM 3 (Beijing Beihua Fine Chemicals Co., Ltd.) solution and ascorbic acid (Beijing Baierdi Biotechnology Co., Ltd.) solution with a mass concentration of 2%, mixed with a volume ratio of 1:2, ultrasonically treated for 45s, and the ultrasonic power was 70W. Obtain silver colloidal solution;

[0030] Prepare AgNO at a concentration of 6mM 3 (Beijing Beihua Fine Chemicals Co., Ltd.) solution, mixed with the above-mentioned octreotide acetate solution and silver colloid solution in a volume ratio of 1:1:2, placed in a digital display double-layer air bath constant temperature oscillator, at 150rpm., Incubate at 20°C for 30 hours;

[0031]...

Embodiment 3

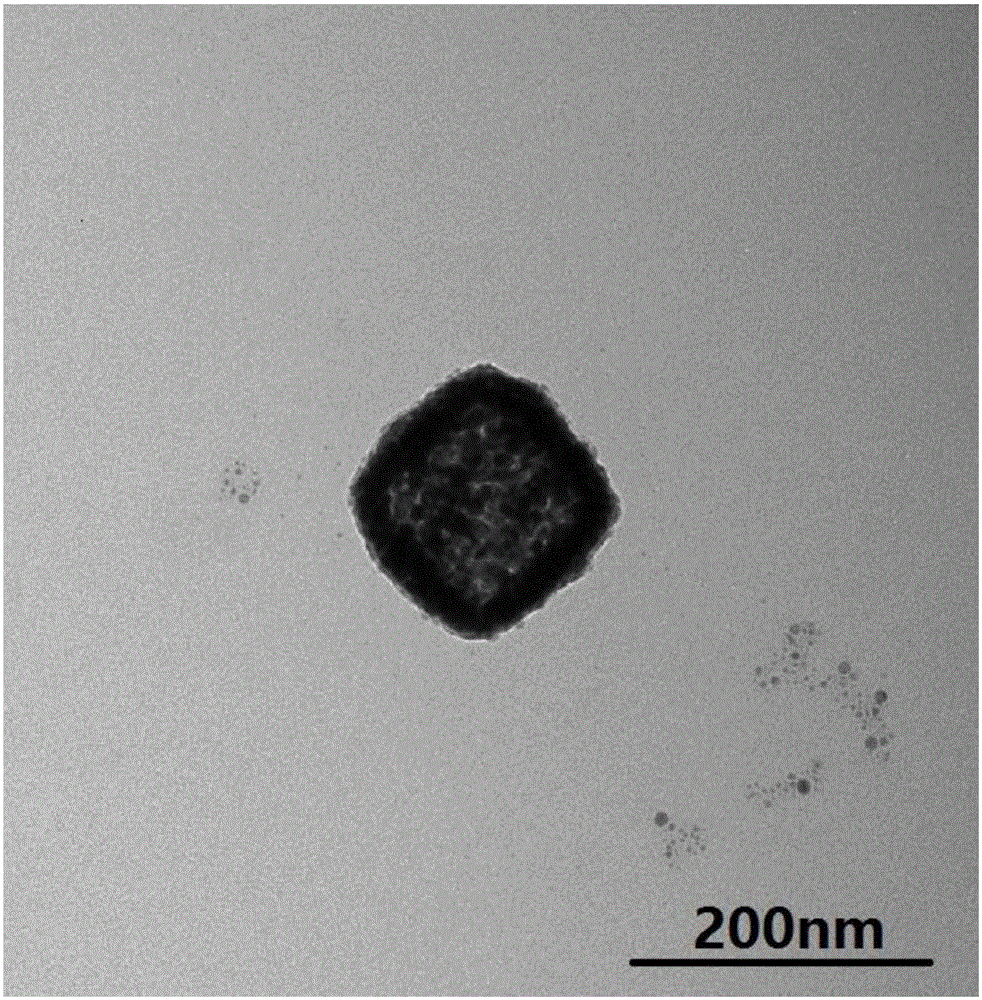

[0034] Dissolve octreotide acetate (Shanghai Taishi Biotechnology Co., Ltd.) in hydrochloric acid (Yongfei Chemical Factory) solution to prepare an octreotide acetate solution with a concentration of 0.3mM and a pH value of 1, and place it in a constant temperature metal bath at 90°C for 10 minutes ;

[0035] Prepare AgNO at a concentration of 1.2mM 3 (Beijing Beihua Fine Chemicals Co., Ltd.) solution and ascorbic acid (Beijing Baierdi Biotechnology Co., Ltd.) solution with a mass concentration of 1% were mixed at a volume ratio of 1:3, and ultrasonic treatment was performed for 1 min, and the ultrasonic power was 60W. Obtain silver colloidal solution;

[0036] Prepare AgNO at a concentration of 4mM 3 (Beijing Beihua Fine Chemicals Co., Ltd.) solution, mixed with the above-mentioned octreotide acetate solution and silver colloid solution at a volume ratio of 1:1:1, placed in a digital display double-layer air bath constant temperature oscillator, at 100rpm., Incubate at 30°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com