Processing method of aluminum alloy booster explosive cartridge class parts

A technology for parts processing and booster, which is applied in the field of aluminum alloy booster cartridge parts processing, can solve the problems of high processing cost, low material utilization rate, poor rigidity of parts, etc., so as to improve the material utilization rate and the inner hole. Roughness, the effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

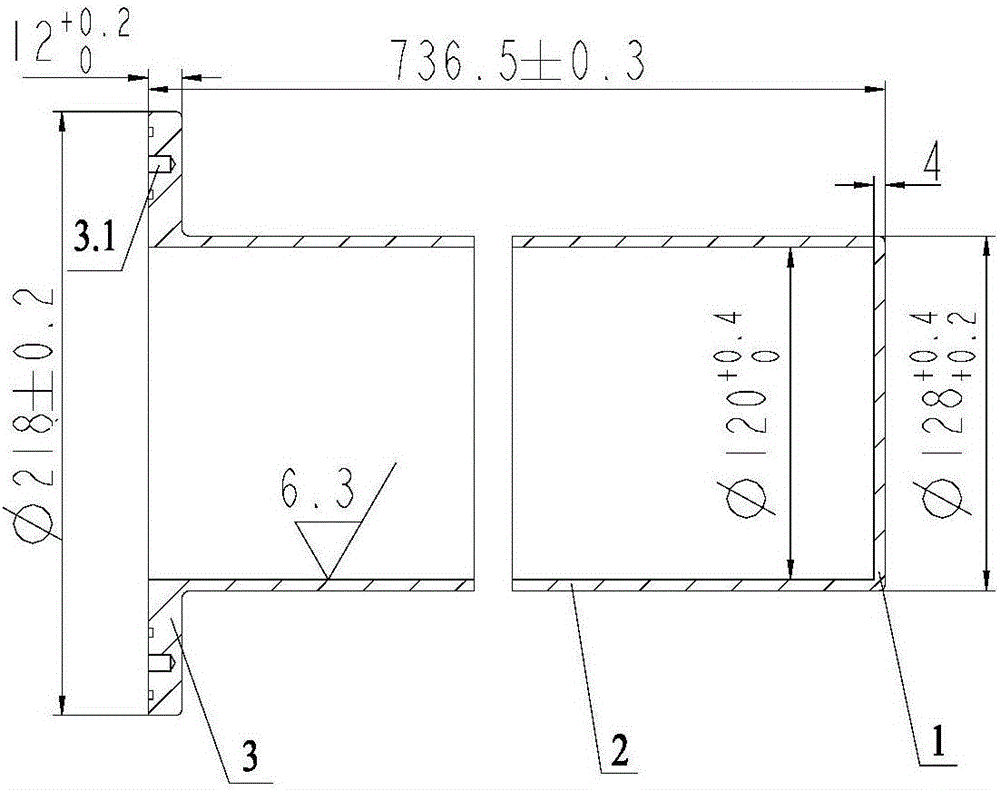

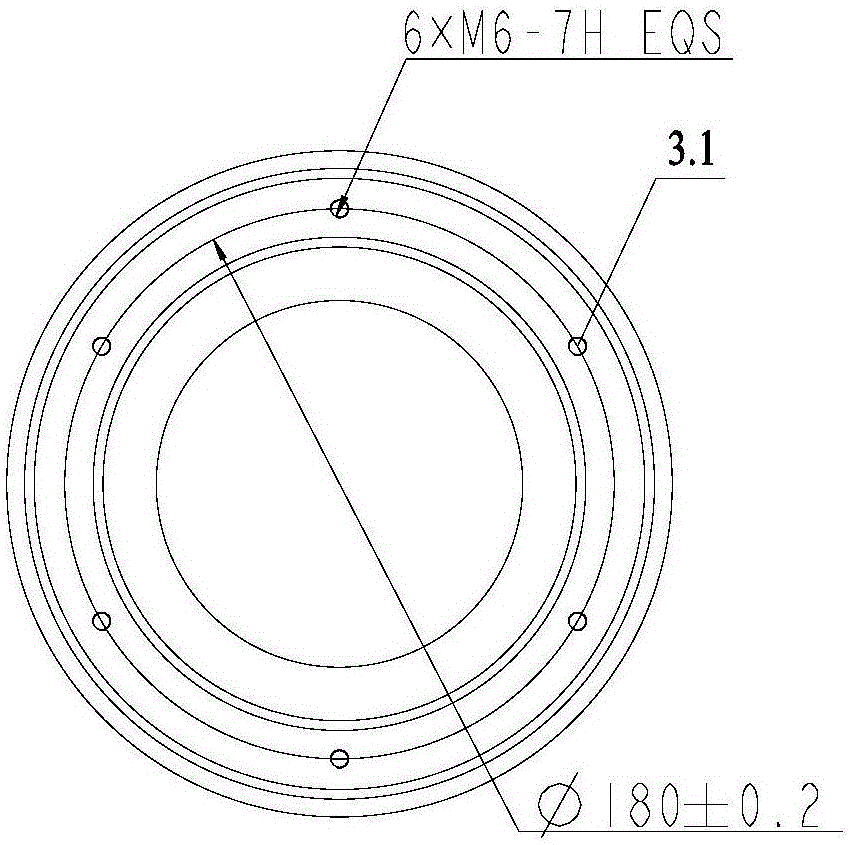

[0039] Such as figure 1 , figure 2As shown, for a certain missile, the overall detonation warhead charge body booster cartridge parts include cartridge 2 (that is, the part of the booster cartridge with thin wall and large aspect ratio), and the plug 1 at one end of the cartridge 2. And the flange 3 at the other end of the cartridge 2, its large flange (diameter Thickness 12mm), thin-walled blind hole (wall thickness and bottom thickness 4mm), large aspect ratio (inner hole diameter The forming process of length 736.5mm) is as follows:

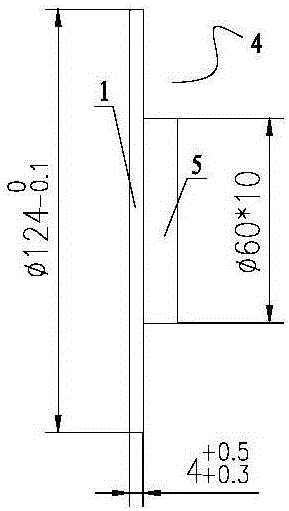

[0040] 1) Formed cap assembly 4: The cap assembly is formed by processing an aluminum rod. The cap assembly 4 includes a cap 1 at the big end and a process chuck 5 at the small end,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com