Multi-shell graphite phase carbon nitride hollow nanosphere and synthesis method and application thereof

A technology of graphite phase carbon nitride and hollow nanometers, which is applied in the direction of nitrogen compounds, chemical instruments and methods, nitrogen and non-metallic compounds, etc., to achieve the effects of facilitating utilization, shortening the transmission path, and making the preparation method simple and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, double shell g-C 3 N 4 The synthetic method of hollow nanosphere comprises the following steps:

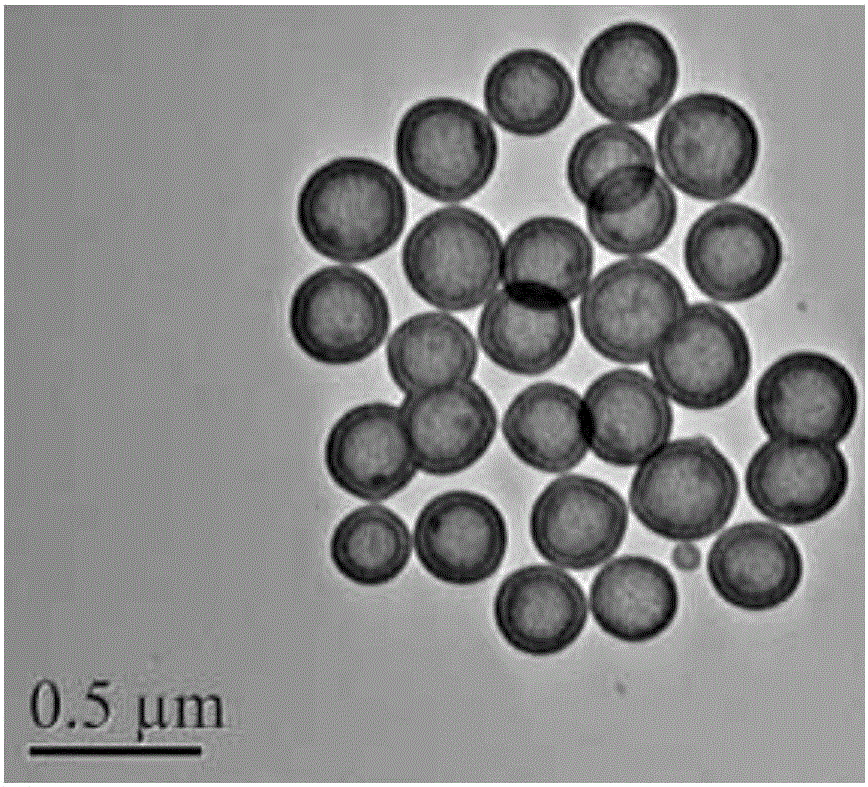

[0028] Step 1. At room temperature, configure solution A containing 0.5ml of ammonia water, 30ml of ethanol, and 75ml of deionized water, add 80mg of surfactant CTAB to it, and continue stirring for 1 hour; mix 0.0625ml of TEOS and 0.0625ml of BTSE , was added to the above solution A under the condition of rapid stirring, so that the molar ratio of TEOS to ethanol was kept at 1:921. After stirring for 24 hours, add 0.0625ml of TEOS and 0.0625ml of BTSE again, continue stirring for 24 hours to obtain a suspension, centrifuge the suspension to obtain silicone balls, hollow the silicon balls by hydrothermal treatment, and remove CTAB by acid treatment. Double shell SiO 2 Hollow nanospheres, such as figure 1 As shown, it can be seen that SiO 2 The nanospheres present a hollow structure. In the present invention, in this step, according to the difference in t...

Embodiment 2

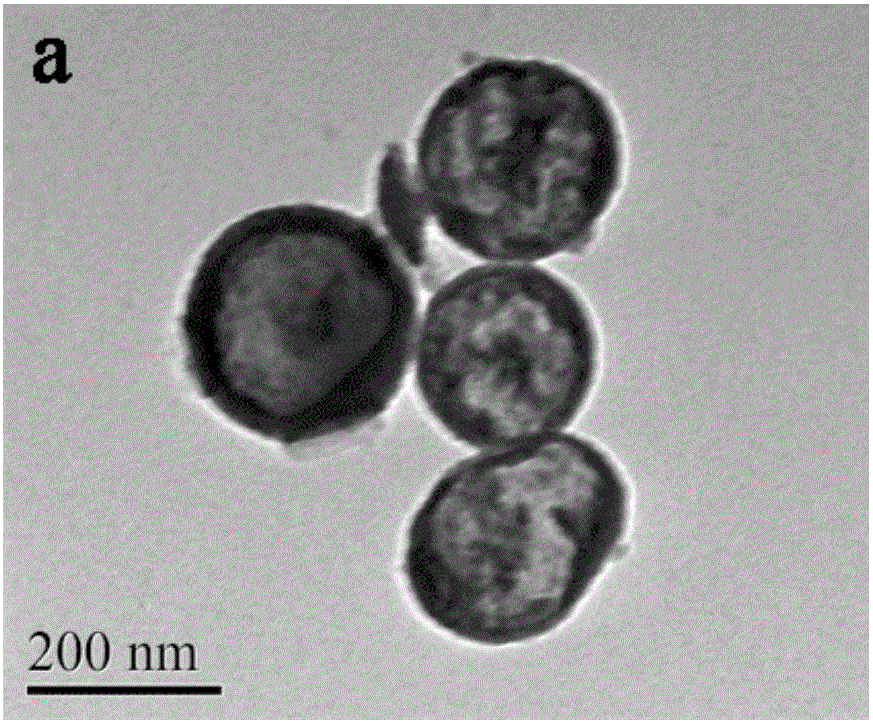

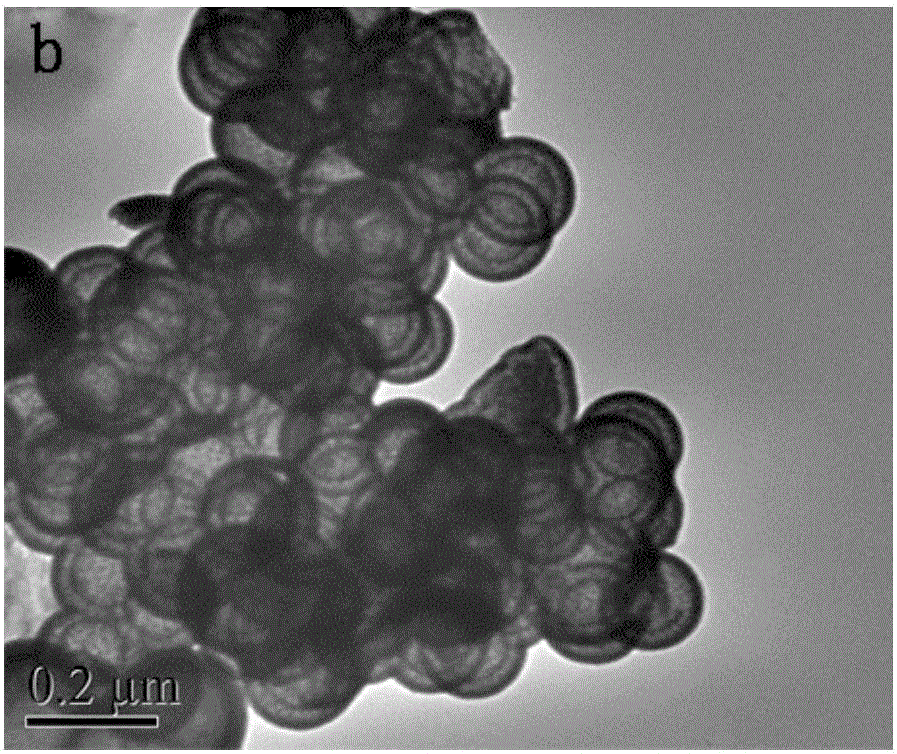

[0031] Embodiment 2, triple shell g-C 3 N 4 The synthesis of hollow nanospheres, its steps are basically the same as in Example 1, the difference is only: in the process of forming organosilicon spheres in step 1, an equal volume of TEOS and BTSE was added once more, and stirring was continued for 24 hours, that is, a total of The process of adding equal volumes of TEOS and BTSE and stirring for 24 hours was carried out three times, and the three-shelled g-C was finally prepared. 3 N 4 Hollow nanosphere, and denoted as TS-g-C 3 N 4 . Figure 2(c) shows the TS-g-C 3 N 4 The TEM photo of the TS-g-C in Fig. 2(d) 3 N 4 The mapping spectrum, it can be seen that the prepared TS-g-C 3 N 4 It presents a hollow and multi-shell structure, and the carbon and nitrogen elements are evenly distributed throughout the hollow sphere; the particle size is 300-400nm, and the shell spacing is about 20-40nm.

[0032] image 3 It is the single, double and triple shell g-C prepared in Com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com