Adhesive-free AEI/MFI eutectic silicon-aluminum molecular sieves as well as synthetic method and application

A silica-alumina molecular sieve and a synthesis method technology are applied in the application fields of conversion rate and yield, and can solve the problems of weak acidity, low reactivity, single pore size of porous materials, etc. The effect of application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) 197.8g ZSM-5 molecular sieve (silicon-alumina ratio is 25) was added to 1760.4g concentration of 39.1wt% glucose solution, stirred for 30min and placed in an ultrasonic cleaner for 2h, then the mixture was filtered to obtain The product was dried at 120° C. for 24 hours, and then calcined at 500° C. for 2 hours in a nitrogen atmosphere to obtain a pretreated ZSM-5 molecular sieve.

[0042] (2) Get the above-mentioned pretreated ZSM-5 molecular sieve, 14.69g HY molecular sieve, 409.2g silica gel solution (Ludox-AS30) and deionized water to mix and prepare into a slurry with a solid content of 35%, after spray drying (inlet temperature 140 °C, outlet temperature 80 °C) to obtain microspheres with an average particle size of 60-80 μm, and then calcined at 800 °C for 4 hours to obtain pretreated microspheres.

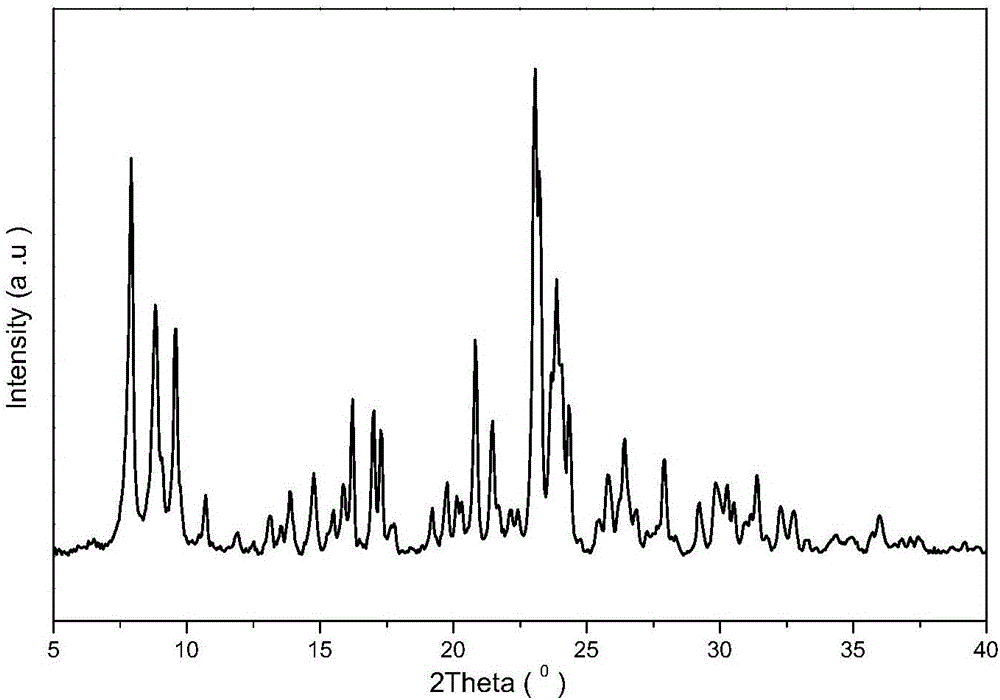

[0043] (3) Mix the above-mentioned pretreated microspheres with 46.57g NaOH, 120.2g of N,N-dimethyl-3,5-dimethylpiperidine (template agent concentration 18.94wt%...

Embodiment 2

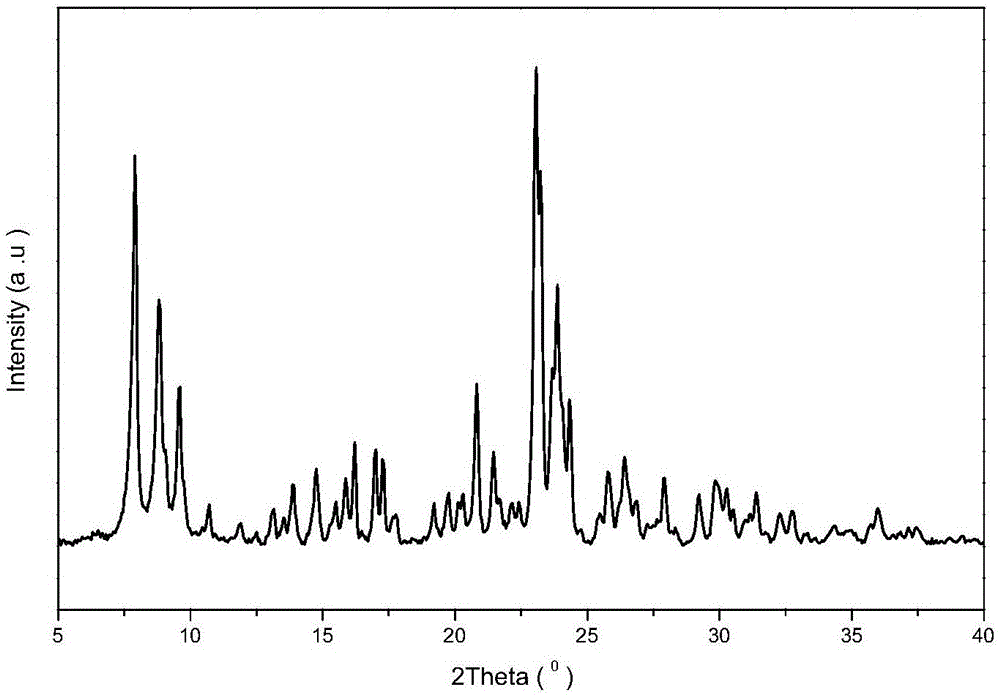

[0046] The process for synthesizing the AEI / MFI eutectic silica-alumina molecular sieve is similar to that of Example 1, except that the slurry concentration for spray drying is 25%, and the template agent used is N,N-dimethyl-2,6-di Methylpiperidine (template agent concentration 20.0wt%), measuring the silicon-aluminum ratio of the eutectic silicon-aluminum molecular sieve is 58.9, and the obtained sodium-type AEI / MFI eutectic silicon-aluminum molecular sieve microspheres use 1.0mol / L concentration zinc nitrate aqueous solution Perform ion exchange. The addition amount of various raw materials synthesized by crystallization is shown in Table 1, figure 2 The XRD diffraction pattern shown in proves that the material is an AEI / MFI eutectic silica-alumina molecular sieve, denoted as B.

Embodiment 3

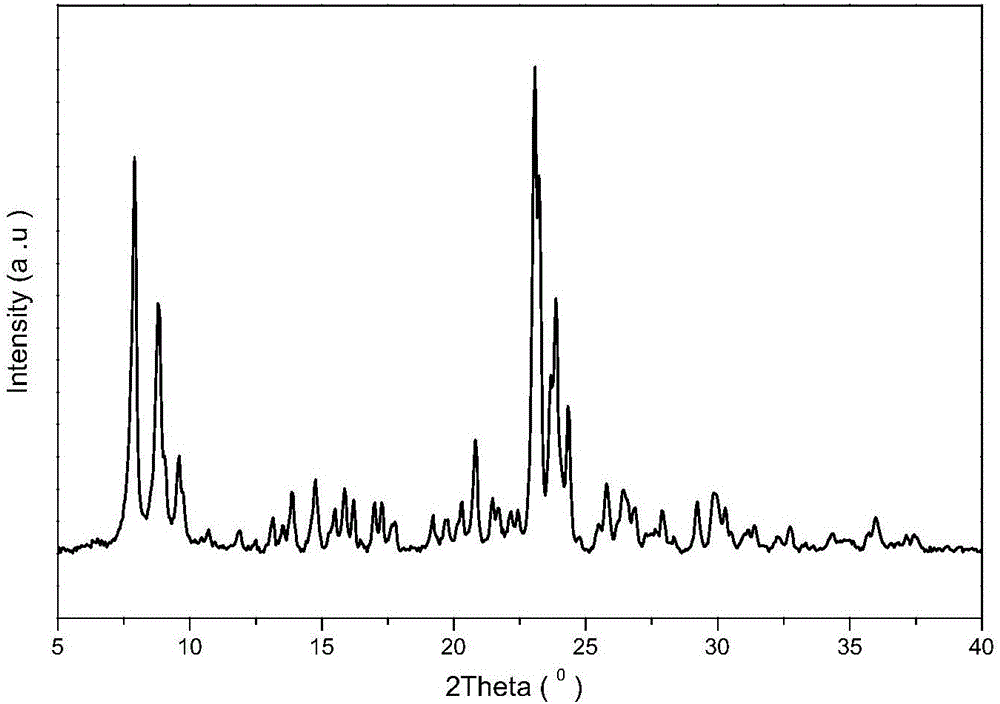

[0048] The process for synthesizing the AEI / MFI eutectic silica-alumina molecular sieve is similar to Example 1, except that the concentration of the slurry for spray drying is 45%, and the template agent used is N,N-diethyl-2,6-di Methylpiperidine (template agent concentration 20.0wt%), measuring the silicon-aluminum ratio of the eutectic silicon-aluminum molecular sieve is 82.7, and the obtained sodium-type AEI / MFI eutectic silicon-aluminum molecular sieve microspheres use 1.0mol / L concentration copper nitrate aqueous solution Perform ion exchange. The addition amount of various raw materials synthesized by crystallization is shown in Table 1, image 3 The XRD diffraction pattern shown in proves that the material is an AEI / MFI eutectic silica-alumina molecular sieve, denoted as C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com