SSZ-39/ZSM-5 composite molecular sieve and synthesis method and application thereof

A composite molecular sieve, SSZ-39 technology, applied in molecular sieve catalysts, including molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low reaction activity, weak acidity, single pore size of porous materials, etc., and achieve high catalytic activity and yield. The effect of improving and enhancing the reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 751.05g of water glass to 178.38g of 25wt% N,N-dimethyl-3,5-dimethylpiperidine (DMDMPOH, represented by "T") in aqueous solution and stir well, then add 26.42g HY molecular sieve with a silicon-aluminum ratio of 5.2, then add 4.71g of NaOH particles in sequence, and add 310.19g of deionized water and stir thoroughly. The resulting mixed slurry was continuously stirred in a sealed container at room temperature for 2 hours until all raw materials were mixed evenly. As the precursor sol synthesized by SSZ-39 molecular sieve, the mixed sol had the following molar composition:

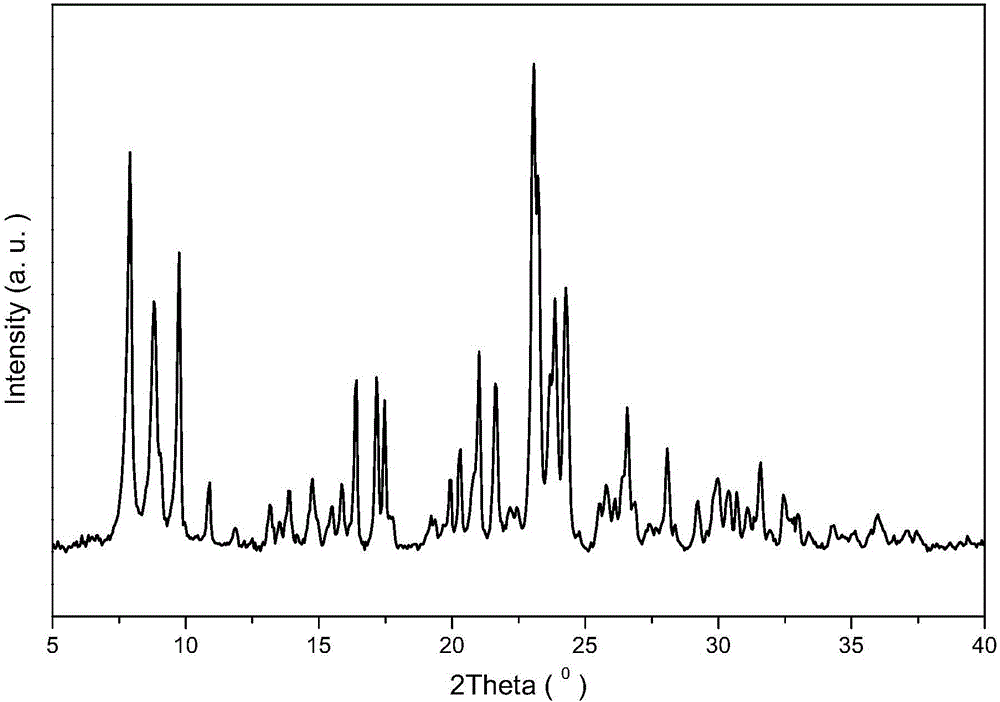

[0037] 0.29Na 2 O: SiO 2 : 0.01786A1 2 o 3 :0.08T:15H 2 o

[0038] 232.43g of HZSM-5 molecular sieve (silicon-alumina ratio is 241) was treated with 1.0mol / L NaOH solution at 90°C for 2 hours according to the ratio of 1g solid: 10ml solution, washed and dried at 120°C for 12 hours, then added to The above SSZ-39 precursor mixed sol was stirred and mixed evenly, then moved to a 2L hydrotherm...

Embodiment 2

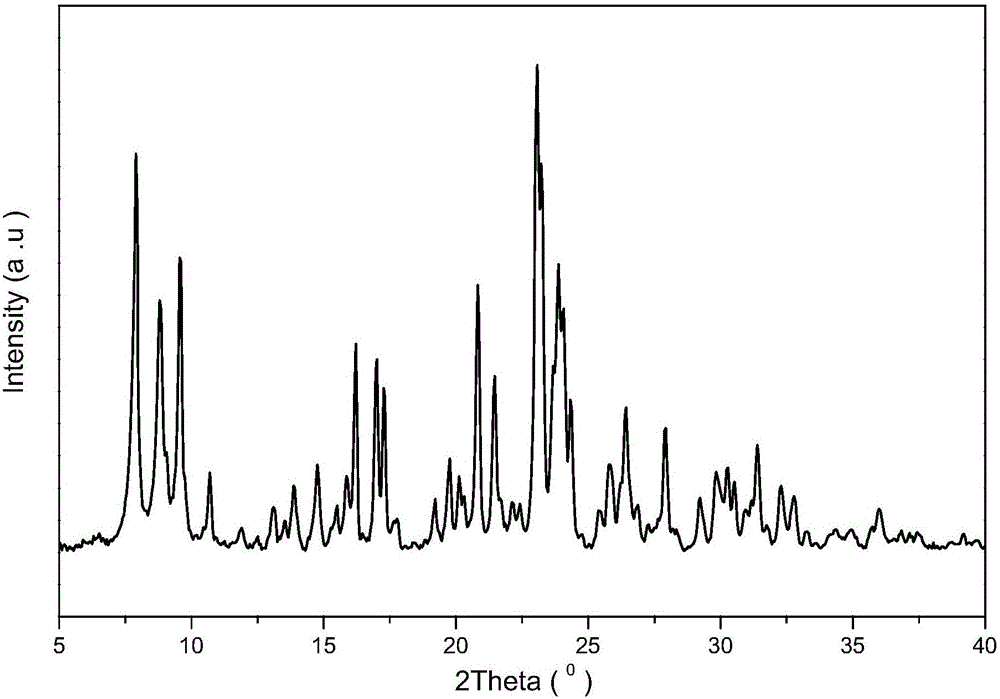

[0041] Using the same experimental method and experimental raw materials as in Example 1 to synthesize SSZ-39 molecular sieves, the difference is the difference in the amount of raw materials added, so that in the sol before the crystallization reaction, silicon source, sodium source, aluminum source, template agent and The molar ratio ratio of the added amount of deionized water constitutes the following molar composition:

[0042] 0.31Na 2 O: SiO 2 : 0.01176A1 2 o 3 :0.09T:25H 2 o

[0043] 291.50g of HZSM-5 molecular sieve (silicon-alumina ratio of 186) was treated with 1.0mol / L NaOH solution at 90°C for 2 hours according to the ratio of 1g solid: 10ml solution, washed and dried at 120°C for 12 hours, then added to The above SSZ-39 precursor solution was re-stirred and mixed evenly, and then moved to a 2L hydrothermal crystallization kettle for crystallization reaction. By the same ammonium ion exchange method as in Example 1, the H-type SSZ-39 / ZSM-5 molecular sieve pr...

Embodiment 3

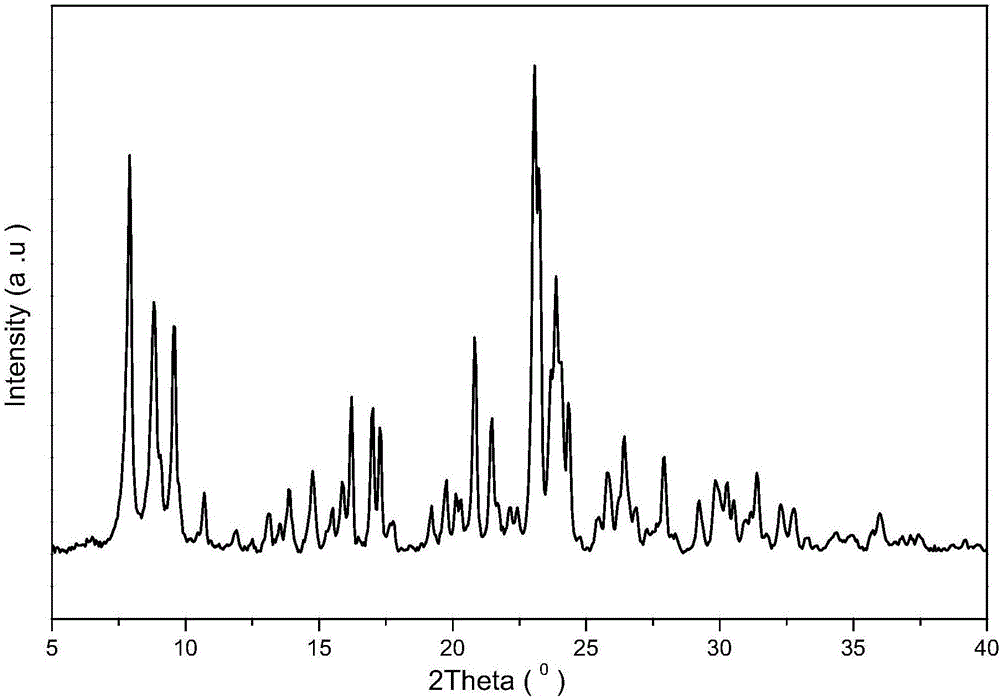

[0045] Using the same experimental method and experimental raw materials as in Example 1 to synthesize SSZ-39 molecular sieves, the difference is the difference in the amount of raw materials added, so that in the sol before the crystallization reaction, silicon source, sodium source, aluminum source, template agent and The molar ratio ratio of the added amount of deionized water constitutes the following molar composition:

[0046] 0.34Na 2 O: SiO 2 : 0.00625A1 2 o 3 :0.15T:35H 2 o

[0047] 391.48g of HZSM-5 molecular sieve (silicon-alumina ratio of 124) was treated with 1.0mol / L NaOH solution at 90°C for 2 hours according to the ratio of 1g solid: 10ml solution, washed and dried at 120°C for 12 hours, then added to The above SSZ-39 precursor solution was stirred and mixed evenly, and then moved to a 5L hydrothermal crystallization kettle for crystallization reaction. By the same ammonium ion exchange method as in Example 1, the H-type SSZ-39 / ZSM-5 molecular sieve produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com