Metal element-containing compound molecular sieve catalyst, and preparation method and application thereof

A composite molecular sieve and metal element technology, applied in molecular sieve catalysts, hydrocarbon production from oxygen-containing organic compounds, chemical instruments and methods, etc., can solve problems such as low yield and selectivity, complex pore structure distribution, and low stability. Achieve the effects of improving yield and selectivity, improving anti-carbon deposition ability, and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

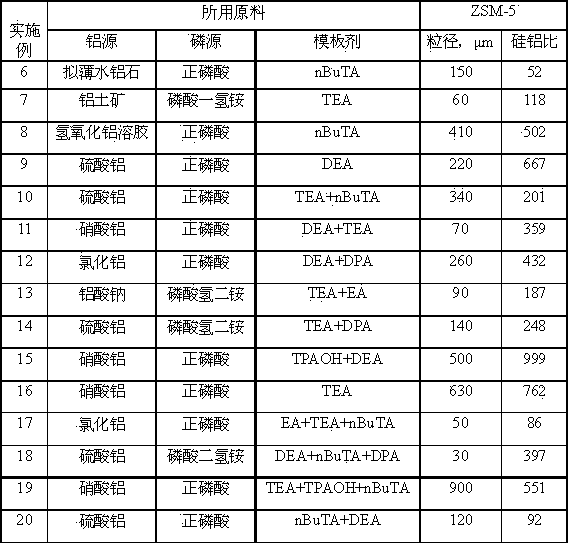

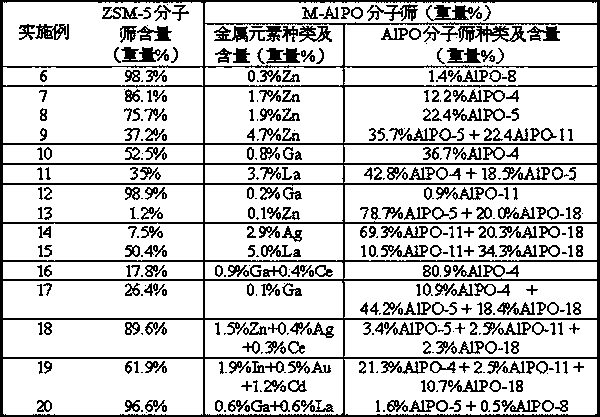

Examples

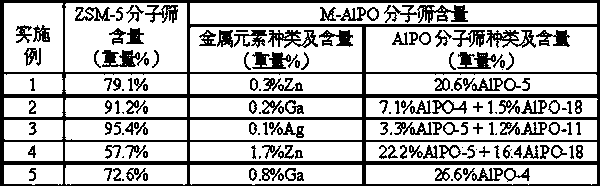

Embodiment 1

[0037] Synthesis of Composite Molecular Sieves Containing Metal Elements

[0038] According to the formula 0.5Al: 1.4P: 0.5TEA: 30H 2 O: 0.15Zn Weigh the reaction raw materials.

[0039] First, fully stir 4.49 grams of aluminum sulfate, 2.42 grams of orthophosphoric acid, 0.61 grams of zinc nitrate and 7.73 milliliters of deionized water to form a uniform jelly, add 0.23 grams of triethylamine under stirring, and wait for the M-AlPO molecular sieve synthetic solution to mix After uniformity, according to liquid / solid = 0.25, put 140.40 grams of ZSM-5 molecular sieves (particle size 200 μm, silicon-aluminum ratio of 18) into the M-AlPO molecular sieve synthesis solution, and finally 150.65 milliliters of deionized water, fully stirred to form a crystallized mixture liquid. The crystallization mixed solution obtained above was crystallized at 130°C and 170°C for 5 hours and 7 days respectively, and the product was centrifuged to obtain a solid product, which was dried in a...

Embodiment 2

[0042] Synthesis of Composite Molecular Sieves Containing Metal Elements

[0043] According to the formula 2Al: 12.9P: 6.5TEA: 50H 2 O: 0.75Ga Weigh the reaction raw materials.

[0044] First, 7.50 grams of aluminum nitrate, 14.87 grams of orthophosphoric acid, 3.13 grams of gallium nitrate and 6.77 milliliters of deionized water were fully stirred and mixed to form a uniform jelly, and 6.58 grams of TEA was added under the stirring state, and after the M-AlPO molecular sieve synthetic solution was mixed evenly According to liquid / solid = 0.13, put 167.88 grams of ZSM-5 molecular sieve (particle size 20 μm, silicon-aluminum ratio 113) into the M-AlPO molecular sieve synthesis liquid, and finally 70.20 ml of deionized water, fully stirred to form a crystallization mixed liquid. The crystallization mixed solution obtained above was crystallized at 60°C and 180°C for 10 days and 5 days respectively, and the product was centrifuged to obtain a solid product, which was dried in an...

Embodiment 3

[0047] Synthesis of Composite Molecular Sieves Containing Metal Elements

[0048] According to the formula 0.1Al: 0.1P: 10.0DEA: 100H 2 O: 0.01Ag Weigh the reaction raw materials.

[0049] First, 2.62 grams of pseudo-boehmite, 0.23 grams of orthophosphoric acid, 0.03 grams of silver nitrate and 35.96 milliliters of deionized water were fully stirred and mixed evenly to form a uniform jelly, and 12.02 grams of TEA was added under the stirring state, and the M-AlPO molecular sieve was synthesized into a liquid After mixing evenly, put 457.74 grams of ZSM-5 molecular sieve (particle size 500 μm, silicon-aluminum ratio of 27) into the M-AlPO molecular sieve synthesis liquid according to liquid / solid = 1:9, and finally 549.29 milliliters of deionized water, fully stirred to form crystallization mixture. The crystallization mixed solution obtained above was crystallized at 80°C and 160°C for 7 days and 10 days respectively, and the product was centrifuged to obtain a solid product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com