A kind of temperature insulation layer material for thermoelectric power generation circuit surface, preparation method and application

A technology of thermoelectric power generation and thermal insulation layer, which is applied in the field of thermal insulation layer material, thermal insulation layer material of thermoelectric power generation pavement, and preparation field, and can solve the problem of low energy acquisition efficiency at the hot end, wide range of heat conduction, affecting the thermoelectric power generation efficiency, etc. problems, to achieve the effect of improving heat collection efficiency and thermoelectric power generation efficiency, light weight and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

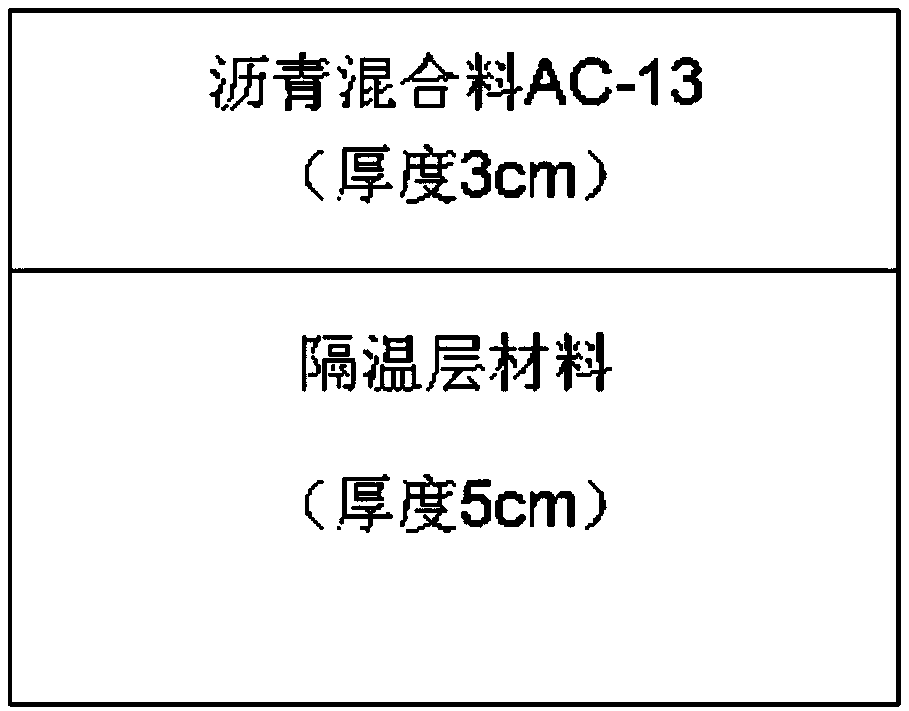

[0050] This embodiment provides a kind of insulation layer material for the temperature difference power generation circuit surface, which is made of the following raw materials in parts by weight: 5 parts of matrix asphalt, 45 parts of diabase aggregate, calcined bauxite particles 25 parts for expanded perlite ore, 7 parts for expanded vermiculite particles, 0.6 parts for potassium hexatitanate whisker powder, 0.15 parts for aluminum silicate fiber, and 0.9 parts for high-viscosity asphalt modifier.

[0051] The preparation method of the temperature insulation layer material used for the temperature difference generating circuit surface of this embodiment is carried out according to the following steps:

[0052] Step 1: put the diabase aggregate, calcined bauxite particles, expanded perlite ore, and expanded vermiculite particles into an oven at 185°C for 10 hours, and put potassium hexatitanate whisker powder into an oven at 175°C Keep warm for 10 hours;

[0053] Step 2: He...

Embodiment 2

[0057] This embodiment provides a kind of insulation layer material for the temperature difference power generation circuit surface, which is made of the following raw materials in parts by weight: 4 parts of matrix asphalt, 35 parts of diabase aggregate, calcined bauxite particles 15 parts for expanded perlite ore, 5 parts for expanded vermiculite particles, 0.5 parts for potassium hexatitanate whisker powder, 0.1 parts for aluminum silicate fiber, and 0.7 parts for high-viscosity asphalt modifier.

[0058] The preparation method of the temperature insulation layer material used for the temperature difference generating circuit surface of this embodiment is carried out according to the following steps:

[0059] Step 1: put the diabase aggregate, calcined bauxite particles, expanded perlite ore, and expanded vermiculite particles into an oven at 185°C for 12 hours, and put potassium hexatitanate whisker powder into an oven at 175°C Keep warm for 12 hours;

[0060] Step 2: Hea...

Embodiment 3

[0064] This embodiment provides a kind of insulation layer material for the temperature difference power generation circuit surface, which is made of the following raw materials in parts by weight: 7 parts of matrix asphalt, 50 parts of diabase aggregate, calcined bauxite particles 35 parts of expanded perlite ore, 15 parts of expanded vermiculite particles, 1 part of potassium hexatitanate whisker powder, 0.2 parts of aluminum silicate fiber, and 1.2 parts of high-viscosity asphalt modifier.

[0065] The preparation method of the temperature insulation layer material used for the thermoelectric circuit surface of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com