Aerogel-containing gypsum material and preparation method thereof

A technology of gypsum material and airgel, which is applied in the field of building materials, can solve the problems that airgel powder and mortar mixture are difficult to compound, airgel cannot be stored for a long time, and airgel is difficult to produce, so as to overcome airgel The effect of uneven dispersion, overcoming airgel dust flying, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of a kind of airgel-containing gypsum material provided by the embodiment of the present invention comprises:

[0021] Uniformly mix the airgel-containing paste, water, thickener and air-entraining agent to form an airgel aqueous dispersion in a uniformly distributed foam state;

[0022] Mix gypsum powder, retarder and water evenly to form a gypsum mixture with standard consistency;

[0023] uniformly mixing the gypsum mixture with the airgel aqueous dispersion to form an airgel-containing mixed slurry;

[0024] The airgel-containing mixed slurry is hardened and dried to obtain the airgel-containing gypsum material.

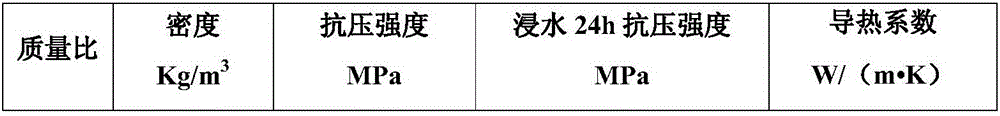

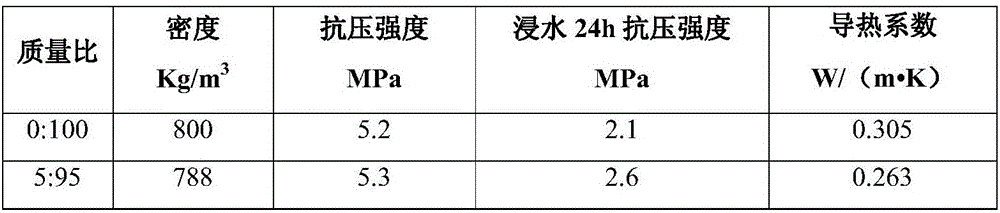

[0025] In some preferred embodiments, the mass ratio of the airgel aqueous dispersion to the gypsum mixture in the aforementioned airgel-containing mixed slurry is (0.1-60): (40-99.9), preferably (10-60 ): (40-90), especially preferably (30-50): (50-70).

[0026] In some preferred embodiments, the preparation method may also inclu...

Embodiment 1

[0057] Embodiment 1 The preparation method of a kind of airgel-containing gypsum material involved in this embodiment comprises:

[0058] The silica airgel powder, deionized water and polyoxyethylene dioleate are uniformly mixed to form an airgel-containing ointment, and the airgel powder is evenly distributed in the ointment. Further, the paste containing airgel includes 15wt% airgel powder, 82wt% water and 3wt% polyoxyethylene dioleate. Further, the thermal conductivity of the coating formed by the aerogel-containing paste in a dry state is 0.041 W / m·K. Among them, the density of silica airgel powder is 0.065g / ml, the particle size is 0.16μm, and the specific surface area is 1150m 2 / g, the thermal conductivity is 0.024W / m·k.

[0059] Mix the airgel-containing ointment, lignin fiber and deionized water, and then stir the above mixture until it is completely dispersed, then add sodium dodecylbenzenesulfonate to the above solution, and use high-speed stirring equipment to mi...

Embodiment 2

[0066] Embodiment 2 The preparation method of a kind of airgel-containing gypsum material involved in this embodiment includes:

[0067] Titanium dioxide airgel powder, deionized water and polyoxyethylene sorbitol lanolin oleic acid derivative are evenly mixed to form an airgel-containing ointment, and the airgel powder is evenly distributed in the ointment. Further, the airgel-containing ointment includes 30wt% titanium dioxide airgel powder, 65wt% water and 5wt% polyoxyethylene sorbitan lanolin oleic acid derivative. Further, the thermal conductivity of the coating formed by the aerogel-containing paste in a dry state is 0.021 W / m·k. Among them, the density of titanium dioxide airgel powder is 0.25g / ml, the particle size is 0.020mm, and the specific surface is 650m 2 / g, the thermal conductivity is 0.015W / m·k.

[0068] Mix the ointment containing airgel, polyethylene glycol and deionized water, and then stir the above mixture until it is completely dispersed, then add sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com