Rubber additive as well as preparation and application thereof

An additive and rubber technology, applied in the field of tire rubber additives, can solve problems such as reduction and achieve the effect of improving tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

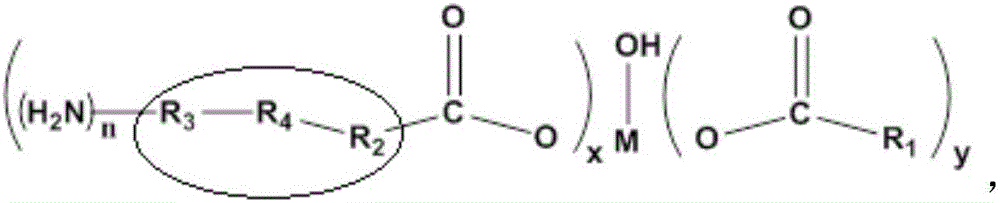

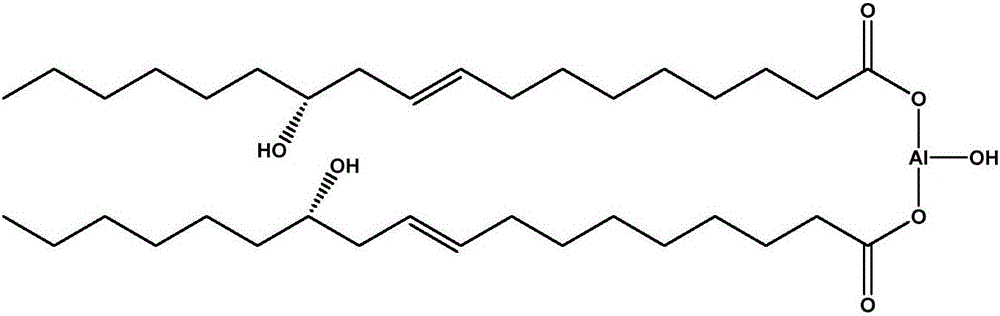

[0043] A kind of rubber additive, its chemical structural formula is:

[0044]

[0045] The preparation method of above-mentioned metallic soap, comprises the following steps:

[0046] (1) Add 1 L of distilled water and 128.18 g of sodium ricinoleate (purity ≥ 90%, purchased from TCI) into a 2 L beaker. The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution A)

[0047] (2) Another 2L beaker was taken, and 1L of distilled water and 94.8g of potassium aluminum sulfate dodecahydrate (purity ≥ 99%, purchased from Aladdin) were added into it. The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution D)

[0048] (3) Finally, with the solution A being vigorously stirred, the solution D was slowly poured into the solution A at a speed of 10 mL / s to obtain a milky white solid product. The resulting white solid product was washed 5 time...

Embodiment 2

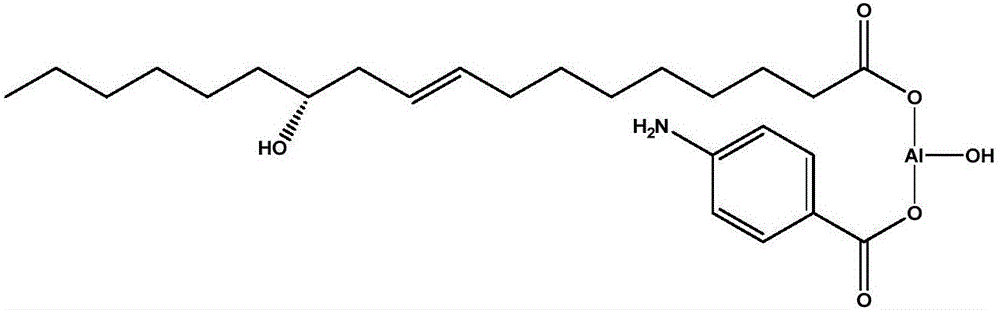

[0050] A kind of rubber additive, its chemical structural formula is:

[0051]

[0052] The preparation method of above-mentioned metallic soap, comprises the following steps:

[0053] (1) Add 1 L of distilled water and 4 g of solid sodium hydroxide (purity ≥ 97%, purchased from Aladdin) in a 2 L beaker. After the sodium hydroxide was completely dissolved, 27.4 g of 4-aminobenzoic acid (purity ≥ 98%, purchased from Aladdin) was added. The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution B)

[0054] (2) Add 1 L of distilled water and 64.9 g of sodium ricinoleate (purity ≥ 90%, purchased from TCI, and can be formed by reacting ricinoleic acid and sodium carbonate at a molar ratio of 2:1) into a 2 L beaker. The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution A)

[0055] (3) Another 2L beaker was taken, and 1L of distilled...

Embodiment 3

[0058] A kind of rubber additive, its chemical structural formula is:

[0059]

[0060] The preparation method of above-mentioned metallic soap, comprises the following steps:

[0061] (1) Add 1 L of distilled water and 6.87 g of solid sodium hydroxide (purity ≥ 97%, purchased from TCI) into a 2 L beaker. After the sodium hydroxide was completely dissolved, 116.37 g of erucic acid (purity ≥ 85%, purchased from Aladdin) was added. The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution A)

[0062] (2) Another 2L beaker was taken, and 1L of distilled water and 81.52g of potassium aluminum sulfate dodecahydrate (purity ≥ 99%, purchased from Aladdin) were added into it. The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution D)

[0063] (3) Finally, with the solution A being vigorously stirred, the solution D was slowly poured in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ring outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com