Method for preparing polymer fat-liquoring agent of sulfosuccinate structure

A sulfosuccinate and polymer technology, which is applied in small raw hide/large hide/leather/fur treatment, leather impregnation, application, etc. Poor performance and other problems, to achieve the effect of reducing COD content, strong binding ability, and many binding groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

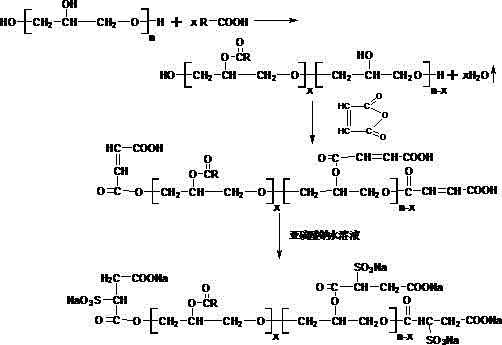

[0018] A kind of preparation method that has sulfosuccinate salt structure polymer fatliquoring agent, specifically comprises the following several steps:

[0019] (1) Add 0.1mol 6-polyglycerol and 0.4mol stearic acid into the reactor, blow in nitrogen, raise the temperature to 240°C, and perform esterification reaction for 3 hours to obtain Intermediate A;

[0020] (2) Intermediate A was cooled to 70°C, 0.4mol maleic anhydride was added, the temperature was raised to 90°C, and the esterification reaction was carried out for 3 hours to obtain Intermediate B;

[0021] (3) Cool down the intermediate B to 70°C, add 168g of 30% sodium sulfite aqueous solution, react at 85°C for 3 hours, and obtain a polymer fatliquoring agent with a sulfosuccinate salt structure after cooling down.

Embodiment 2

[0023] A kind of preparation method that has sulfosuccinate salt structure polymer fatliquoring agent, specifically comprises the following several steps:

[0024] (1) Add 0.1 mol of 10-polyglycerol and 0.6 mol of stearic acid into the reactor, blow nitrogen gas, heat up to 240°C, and perform esterification reaction for 3 hours to obtain Intermediate A;

[0025] (2) Intermediate A was cooled to 70°C, 0.6mol maleic anhydride was added, the temperature was raised to 90°C, and the esterification reaction was carried out for 3 hours to obtain Intermediate B;

[0026] (3) Cool the intermediate B to 70°C, add 252g of 30% sodium sulfite aqueous solution, react at 85°C for 3 hours, and obtain a polymer fatliquoring agent with a sulfosuccinate salt structure after cooling down.

Embodiment 3

[0028] A kind of preparation method that has sulfosuccinate salt structure polymer fatliquoring agent, specifically comprises the following several steps:

[0029] (1) Add 0.1mol 20-polyglycerol and 1.1mol stearic acid into the reactor, blow nitrogen gas, raise the temperature to 240°C, and perform esterification reaction for 3 hours to obtain intermediate A;

[0030] (2) Intermediate A was cooled to 70°C, 1.1mol of maleic anhydride was added, the temperature was raised to 90°C, and the esterification reaction was carried out for 3 hours to obtain Intermediate B;

[0031] (3) Cool the intermediate B to 70°C, add 462g of 30% sodium sulfite aqueous solution, react at 85°C for 3h, and obtain a polymer fatliquoring agent with a sulfosuccinate salt structure after cooling down.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap