Asphalt emulsifier and preparation method thereof and emulsified asphalt product

An asphalt emulsifier and product technology, applied in the field of composite cold recycling asphalt emulsifier and its preparation, can solve the problems of poor adaptability of asphalt, agglomeration strength of emulsified asphalt mixture, single structure of emulsifier, etc. flexibility, improving affinity, and enhancing the effect of steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides the preparation method of the asphalt emulsifier described in the above technical scheme, comprising the following steps:

[0031] Mixing fatty amide, modified alkali lignin and alkylamide betaine to obtain asphalt emulsifier;

[0032] The preparation method of wherein said modified alkali lignin comprises the following steps:

[0033] Trimethylamine hydrochloride is mixed with epichlorohydrin to carry out a substitution reaction to obtain a substitution reaction product;

[0034] The substitution reaction product is mixed with alkali lignin to obtain modified alkali lignin.

[0035] In the present invention, there is no special restriction on the order of addition when the fatty amide, modified alkali lignin and alkylamide betaine are mixed, and the order of addition well known to those skilled in the art can be adopted; in the embodiment of the present invention It is preferred to mix the fatty amide and alkylamide betaine first, ...

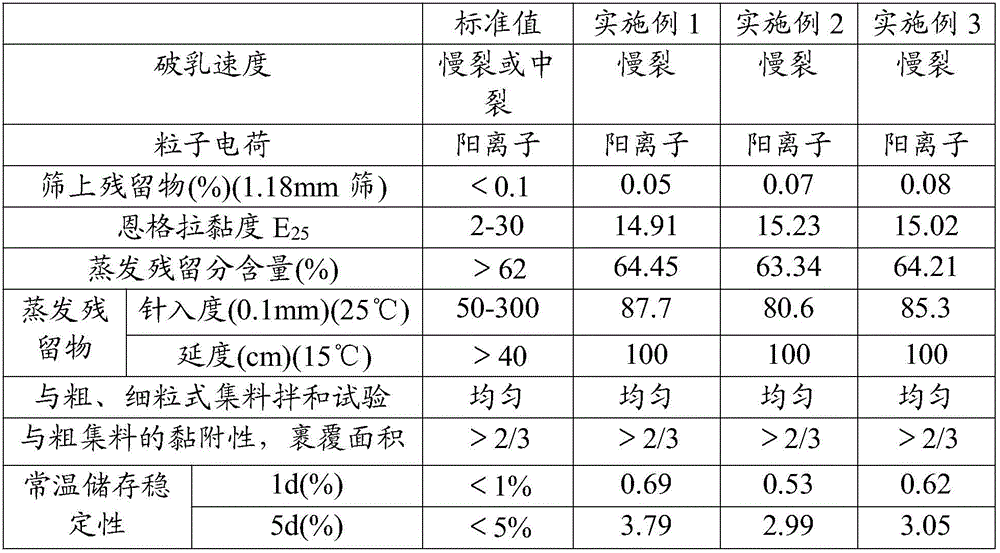

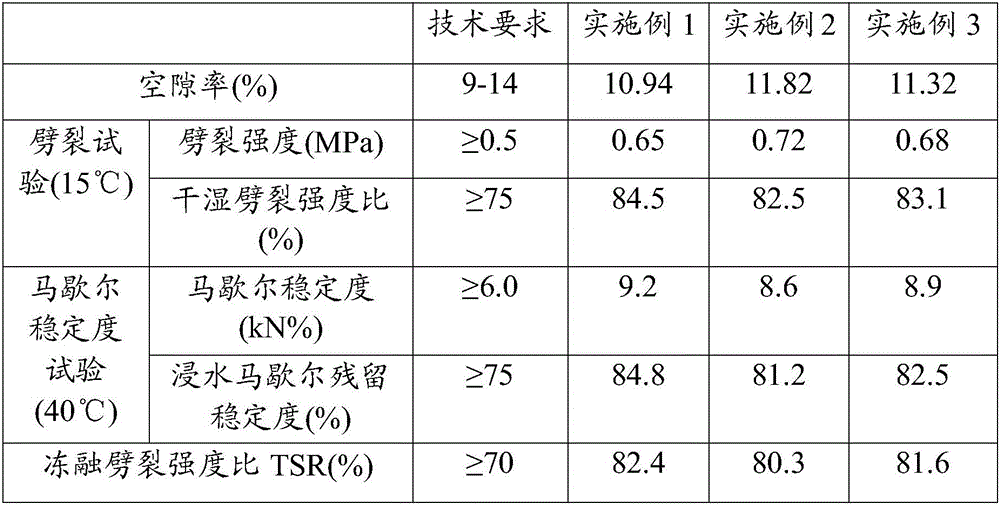

Embodiment 1

[0070] Preparation of asphalt emulsifier

[0071] Add 282g of oleic acid into a three-necked flask, add 51.6g of methacrylic acid, 69.1g of ethanol and react at 155°C for 3h, add 2.2g of 98% concentrated sulfuric acid at 80°C for 3h, then add 302.4g of tetraethylenepentamine at 130°C °C for 1 h, distilled to separate the ethanol at the same time, and continued to heat up to 170 °C for 2 h to obtain a fatty amide.

[0072] Add 95.6 g of solid trimethylamine hydrochloride to the three-necked flask, add 63.7 g of water to dilute it into a 60% aqueous solution, add dropwise 92.5 g of epichlorohydrin and react at 30° C. for 1 h to obtain a substitution reaction product. Add 147g of alkali lignin into a three-necked flask, add 147g of water and 15g of solid sodium hydroxide, add 62.9g of a substitution reaction product, and react at 70°C for 2 hours to obtain modified alkali lignin.

[0073] Stir 60 g of fatty amide and 10 g of octadecamidopropyl betaine at 200 rpm for 10 minutes, ...

Embodiment 2

[0078] Preparation of asphalt emulsifier

[0079] Add 280g of oleic acid to a three-necked flask, add 86g of methacrylic acid, 124g of ethylene glycol and react at 170°C for 6h, add 2.8g of p-toluenesulfonic acid at 80°C for 3h, then add 292.5g of triethylenetetramine at 160°C React for 3 hours, distill to separate ethylene glycol at the same time, continue to heat up to 200°C and react for 2 hours to obtain fatty amide.

[0080] Add 95.6 g of solid trimethylamine hydrochloride to the three-necked flask, add 223 g of water to dilute it into a 30% aqueous solution, add dropwise 111 g of epichlorohydrin and react at 60° C. for 3 h to obtain a substitution reaction product. Add 147g of alkali lignin into a three-necked flask, add 147g of water and 15g of solid sodium hydroxide, add 62.9g of a substitution reaction product, react at 90°C for 5h, and obtain modified alkali lignin.

[0081] Stir 30 g of fatty amide and 40 g of lauryl amidopropyl betaine at 500 rpm for 30 minutes, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com