Biodegradable additive, and plastic product used for food packaging and prepared by using additive

A technology of biodegradation and additives, which is applied in the field of polyethylene film materials and plastic products for food packaging, can solve the problems of difficult wide-scale promotion, poor antibacterial performance, and high cost of biodegradable plastics, and achieve the effect of avoiding white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] Preparation of biodegradable additives

[0019] The biodegradable additive of the present invention is prepared from the following raw materials: 5-10% by mass (preferably 8% by mass) of ultrafine iron powder with a particle diameter of 5 microns or less, 0.01-0.20% by mass of silane coupling agent, 0.02-0.20% by mass of titanic acid coupling agent 0.40% by mass, and the balance is low-density polyethylene.

[0020] In a further embodiment, the silane coupling agent is vinyltriethoxysilane, and the titanic acid coupling agent is isopropyl tris(dioctyl pyrophosphate acyloxy) titanate, so Said low-density polyethylene adopts low-density polyethylene with a lower melting point, and its consumption is 91.4-92.97% by mass.

[0021] The biodegradable additive of the present invention is prepared by the following steps:

[0022] Step 1: Weigh the components in the above mass percentages, and use a silane coupling agent and a titanic acid coupling agent to carry out surface ...

Embodiment 1

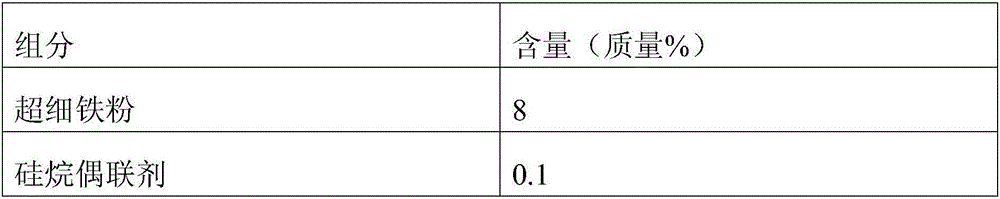

[0026] Table 1: Composition of Biodegradable Additive 1

[0027] components Content (mass%) Ultrafine iron powder 8 A silane coupling agent 0.01 Titanic acid coupling agent 0.2 Low-density polyethylene 91.79

[0028] First adopt the silane coupling agent and the titanic acid coupling agent of the percentage by weight in Table 1 to carry out surface treatment to the superfine iron powder of predetermined content; Then put the ultrafine iron powder and low-density polyethylene after surface treatment together into agitator Mixing; put the mixed material into a twin-screw granulator to make granules with the same shape and similar size as polyethylene plastic granules.

Embodiment 2

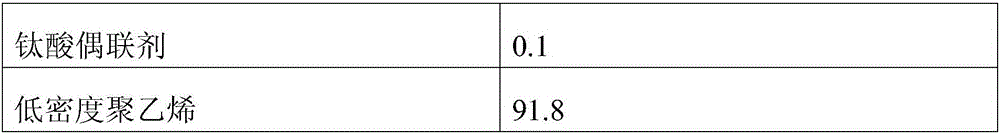

[0030] Table 2: Composition of Biodegradable Additive 2

[0031]

[0032]

[0033] Except for the difference in mass percentage (as shown in Table 2), the biodegradable additive was prepared by the same preparation method as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com