Dyeing master batch for polypropylene-polyethylene bi-component fiber and preparation method thereof

A technology of bicomponent fiber and coloring masterbatch, which is applied in the field of coloring masterbatch, coloring masterbatch for polypropylene-polyethylene bicomponent fiber and its preparation, can solve the problem that the coloring masterbatch cannot meet the production needs, and the spinneret is changed. Long board cycle, high production and maintenance costs, to improve production efficiency and product quality, reduce production costs, and reduce downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

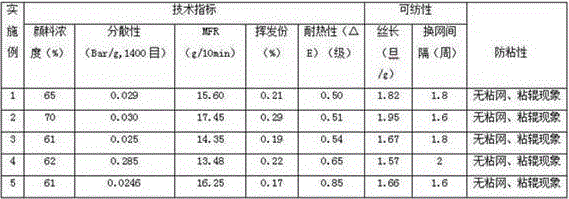

Examples

Embodiment 1

[0029] A kind of polypropylene-polyethylene two-component fiber coloring masterbatch is composed of the following raw materials in parts by mass: rutile titanium dioxide R 249 65 parts, 10 parts of carrier A, 22 parts of carrier B, 1 part of silicone oil, 1 part of anti-sticking agent PPA, 1 part of zinc stearate.

[0030] In this embodiment, the melt index of carrier A is 5 g / 10 min, and the melt index of carrier B is 40 g / 10 min.

[0031] In this example, the formula of PPA is: 0.04 part of fluororesin F-2, 0.2 part of carrier A, 0.75 part of carrier B, and 0.01 part of zinc stearate.

[0032] In this example, the rutile titanium dioxide R 249 The average particle size is 0.16 μm, and its pressure filtration value under the condition of 1400 mesh filter screen is 0.19Bar / g.

Embodiment 2

[0034] A kind of polypropylene-polyethylene two-component fiber coloring masterbatch is composed of the following raw materials in parts by mass: rutile titanium dioxide R 108 70 parts, 5 parts of carrier A, 25 parts of carrier B, 0.5 parts of silicone oil, 1 part of PPA, 1 part of zinc stearate.

[0035] In this embodiment, the melt index of carrier A is 8 g / 10 min, and the melt index of carrier B is 65 g / 10 min.

[0036] In this example, the formula of PPA is: 0.04 part of fluororesin F-2, 0.3 part of carrier A, 0.65 part of carrier B, and 0.01 part of zinc stearate.

[0037] In this example, the rutile titanium dioxide R 108 The average particle size is 0.15 μm, and its pressure filtration value under the condition of 1400 mesh filter screen is 0.016Bar / g.

Embodiment 3

[0039] A coloring masterbatch for polypropylene-polyethylene bicomponent fibers, which consists of the following raw materials in parts by mass: 35 parts of phthalocyanine green, 15 parts of cadmium yellow, 6 parts of carrier A, 24 parts of carrier B, and 1 part of silicone oil , 0.5 part of PPA, 0.5 part of zinc stearate.

[0040] In this embodiment, the melt index of carrier A is 10 g / 10 min, and the melt index of carrier B is 45 g / 10 min.

[0041] In this example, the formula of PPA is: 0.04 part of fluororesin F-2, 0.35 part of carrier A, 0.6 part of carrier B, and 0.01 part of zinc stearate.

[0042] In this embodiment, the average particle diameter of the pigment is 0.17 μm, and its pressure filtration value under the condition of a 1400-mesh filter is 0.023 Bar / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com