A kind of thermally conductive silicone gel and preparation method thereof

A technology of silicone and gel, which is applied in the field of liquid silicone rubber, can solve the problems of low hardness and low thermal expansion rate, and achieve the effect of low hardness, low thermal expansion rate and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A heat-conducting silicone gel, comprising the following component A in parts by weight: 100 parts of base glue, 7 parts of vinyl silicone oil, 1 part of inhibitor, 2 parts of catalyst, B component: 100 parts of base glue, vinyl 1 part of silicone oil, 4 parts of hydrogen-containing silicone oil, and 5 parts of chain extender; the base rubber includes 100 parts of vinyl silicone oil, 50 parts of flame retardant additives, 250 parts of filler, and 18 parts of silane treatment agent.

[0035] In this embodiment, the kinematic viscosity of the vinyl silicone oil at 25° C. is 3000 Pa·s.

[0036] In this example, the inhibitor is 3-methyl-1-hexynyl-3-ol.

[0037] In this embodiment, the catalyst is a platinum chelate compound of alkenyl siloxane, and the platinum content is 5000 ppm.

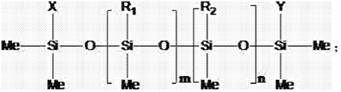

[0038] In this embodiment, the structural formula of the chain extender is:

[0039] , where X, Y are CH 3 , H; R 1 , R 2 for CH 3 、C 2 h 5 ; m=100, n=50.

[0040] In this embodimen...

Embodiment 2

[0044] A heat-conducting silicone gel, comprising the following component A in parts by weight: 100 parts of base glue, 6 parts of vinyl silicone oil, 1 part of inhibitor, 3 parts of catalyst, B component: 100 parts of base glue, vinyl 2 parts of silicone oil, 2 parts of hydrogen-containing silicone oil, and 3 parts of chain extender; the rubber base includes 100 parts of vinyl silicone oil, 50 parts of flame retardant additive, 250 parts of filler, and 6 parts of silane treatment agent.

[0045] In this embodiment, the kinematic viscosity of the vinyl silicone oil at 25° C. is 1000 mPa·s.

[0046] In this example, the inhibitor is 2-methyl-3-butynyl-2 alcohol.

[0047] In this embodiment, the catalyst is a chelate compound of chloroplatinic acid and 1,3-divinyltetramethyldisiloxane, and the platinum content is 5000 ppm.

[0048] In this embodiment, the structural formula of the chain extender is:

[0049] , where X and Y are respectively C 2 h 3 , H; R 1 , R 2 Respect...

Embodiment 3

[0055] A heat-conducting silicone gel, comprising the following component A in parts by weight: 100 parts of base glue, 6 parts of vinyl silicone oil, 1 part of inhibitor, 3 parts of catalyst, B component: 100 parts of base glue, vinyl 3 parts of silicone oil, 3 parts of hydrogen-containing silicone oil, and 4 parts of chain extender; the rubber base includes 100 parts of vinyl silicone oil, 150 parts of flame retardant additive, 250 parts of filler, and 5 parts of silane treatment agent.

[0056] In this embodiment, the kinematic viscosity of the vinyl silicone oil at 25° C. is 2000 mPa·s.

[0057] In this example, 1-ethynyl-1-cyclohexanol.

[0058] In this embodiment, the catalyst is a platinum chelate compound of alkenyl siloxane with a platinum content of 3000 ppm.

[0059] In the present embodiment, the structural formula of the chain extender is:

[0060] , where X and Y are respectively C 2 h 3 , H; R 1 , R 2 Respectively CH 3 、C 2 h 5 ; m=50, n=50.

[0061]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com