Preparation method of novel hot-vulcanized liquid silicone rubber

A liquid silicone rubber, thermal vulcanization technology, used in chemical instruments and methods, adhesives, other chemical processes, etc., can solve problems such as unfavorable product control applications, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of preparation method of novel thermal vulcanization liquid silicone rubber, comprises steps as follows:

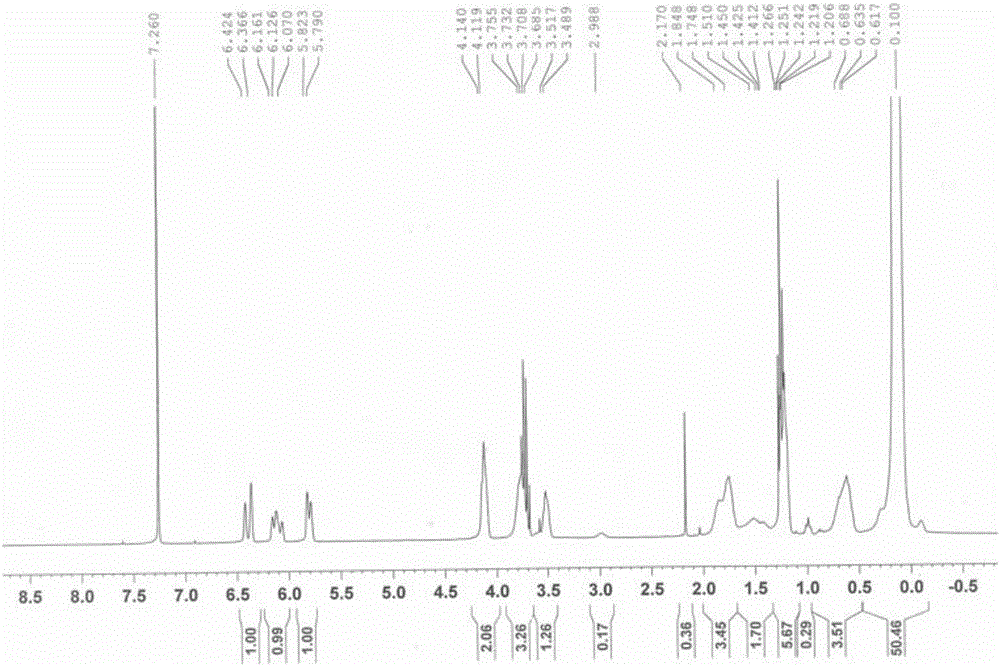

[0041] (1) Add 200g D 4 and 20.2 g of 1,3-bis(3-aminopropyl)-1,1,3,3,-tetramethyldisiloxane were added to a reactor equipped with stirring, nitrogen conduit, thermometer and decompression device , adding 1% of the mass of the total reaction mass of the organic catalyst alkali glue, driving out the air, and raising the temperature to 100° C. for continuous reaction for 36 hours. Then raise the system temperature to 150°C to destroy the organic catalyst, and finally remove the low boilers under reduced pressure to obtain low molecular weight aminopropyl-terminated polydimethylsiloxane as the end-capping agent.

[0042] Weigh 200g D 4 Add 14g of end-capping agent into the reactor equipped with stirring, thermometer and decompression device, add the alkali gum of 2% of the total reaction material mass, react at 110°C for 8h, and then destroy the alkali glue at...

Embodiment 2

[0046] A kind of preparation method of novel thermal vulcanization liquid silicone rubber, comprises steps as follows:

[0047] (1), (2) are with embodiment 1;

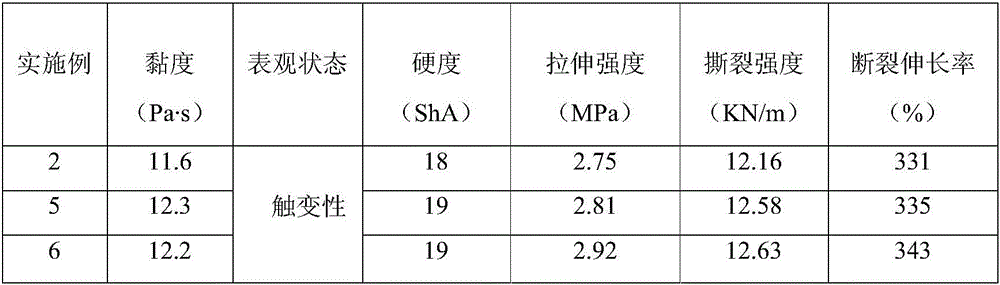

[0048] (3) Weigh 40g of base rubber into a beaker, add 4g of fumed silica and stir evenly, then put it into an oven for heat treatment at 100°C for 40min. Then take out the sample, add 2.0g of low-molecular-weight silicone resin as a cross-linking agent, stir evenly, put it in a vacuum dryer at room temperature to remove air bubbles in a vacuum, take out the sample and pour it into a PTFE mold, and put it in an oven for curing at 100°C for 2 hours , That is, a new heat vulcanized liquid silicone rubber. Its mechanical properties are listed in Table 2.

Embodiment 3

[0050] A kind of preparation method of novel thermal vulcanization liquid silicone rubber, comprises steps as follows:

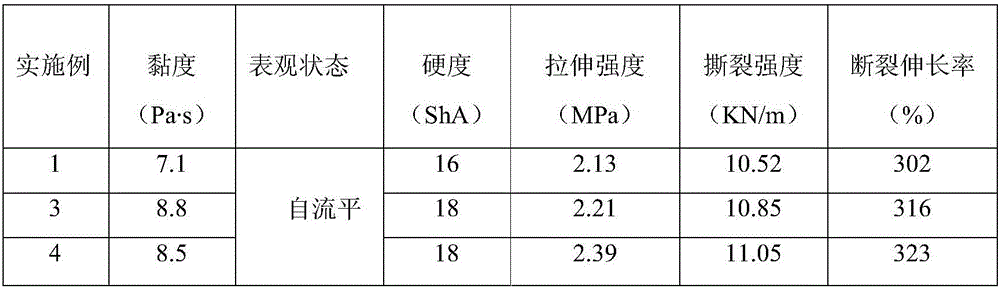

[0051] (1), (2) are with embodiment 1;

[0052] (3) Weigh 40g of base rubber into a beaker, add 2g of fumed silica and stir evenly, then add 2g of precipitated silica and stir evenly, then put it in an oven for heat treatment at 100°C for 40min. Then take out the sample, add 2.0g of low-molecular-weight silicone resin as a cross-linking agent, stir evenly, put it in a vacuum dryer at room temperature to remove air bubbles in a vacuum, take out the sample and pour it into a polytetrafluoroethylene mold, and let it stand for 20 minutes until the surface flows smoothly. Then put it in an oven and cure it at 100°C for 2 hours to obtain a new type of thermally vulcanized liquid silicone rubber. Its mechanical properties are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com