A method for improving the reactivity of coal char gasification

A technology of coal char gasification and reactivity, which is applied in the direction of gasification process, manufacture of combustible gas, petroleum industry, etc., can solve the problems of easy sintering of calcium, decline of catalytic ability, and reduction of catalytic gasification reaction rate, etc., to achieve improved gasification The effects of reactivity, degree of promotion of synergistic effects, good application prospects and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

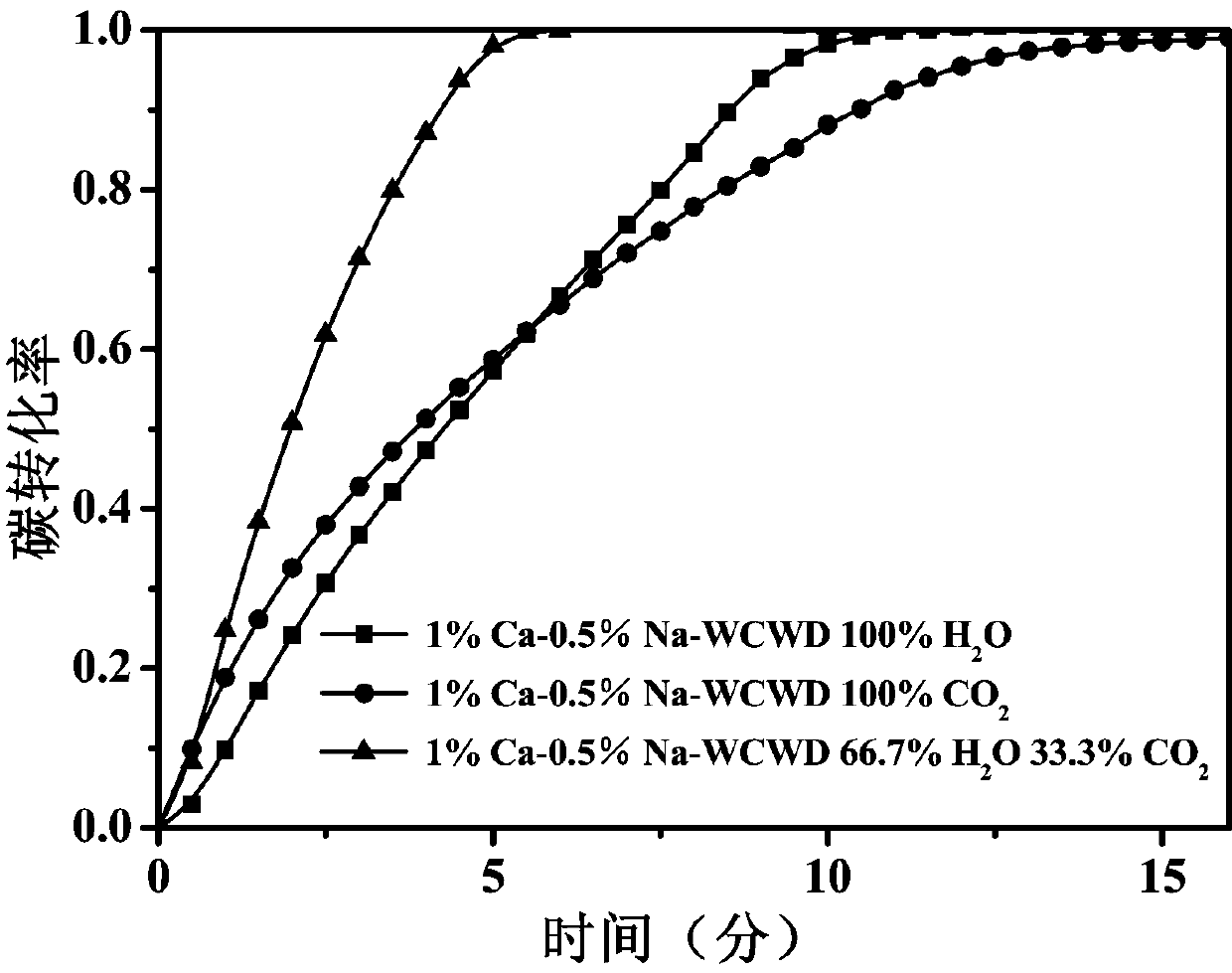

[0026] Example 1: Gasification experiment of deashed Wucaiwan coal.

[0027] Wucaiwan coal is a long-flame coal rich in inertinite from Wucaiwan area of Xinjiang. Its ash composition is characterized by high calcium, high sodium and low clay minerals. The raw coal samples of Wucaiwan were obtained by the quartering method, and after crushing, grinding, and screening, the coal samples with a particle size of less than 0.178mm were selected for experiments.

[0028] The raw coal of Wucai Bay was pickled with HCl and HF to remove minerals. First, mix the coal sample and 6mol / L HCl in a beaker at a ratio of 1g / 10mL, stir at room temperature for 12 hours, filter the mixture of coal sample and HCl, rinse and filter the coal sample with deionized water until the filtrate is medium sex. Subsequently, the coal sample washed with HCl was mixed with 7.6 mol / L HF at a ratio of 1 g / 10 mL, and the above operation was repeated. The obtained demineralized coal was dried in an oven and re...

Embodiment 2

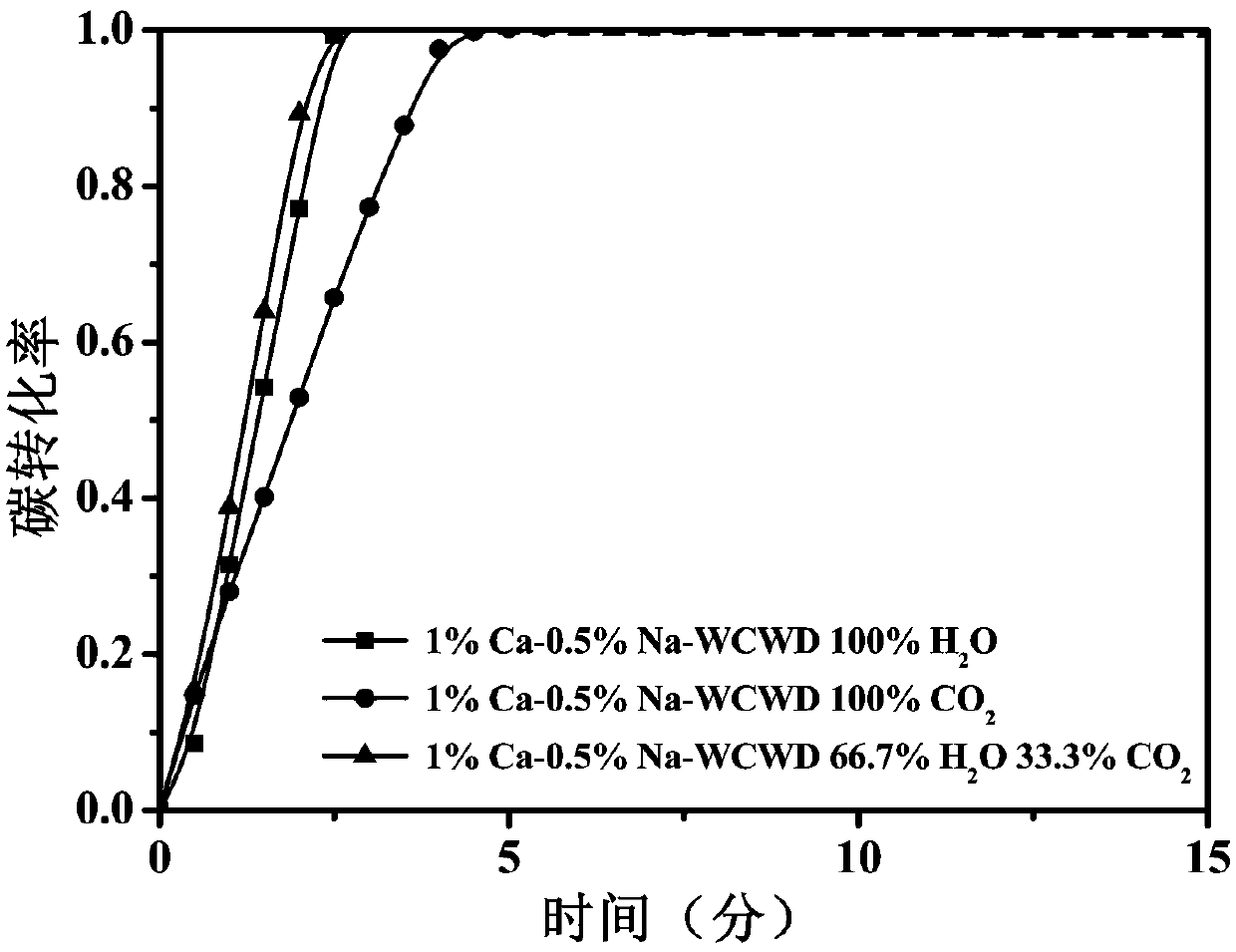

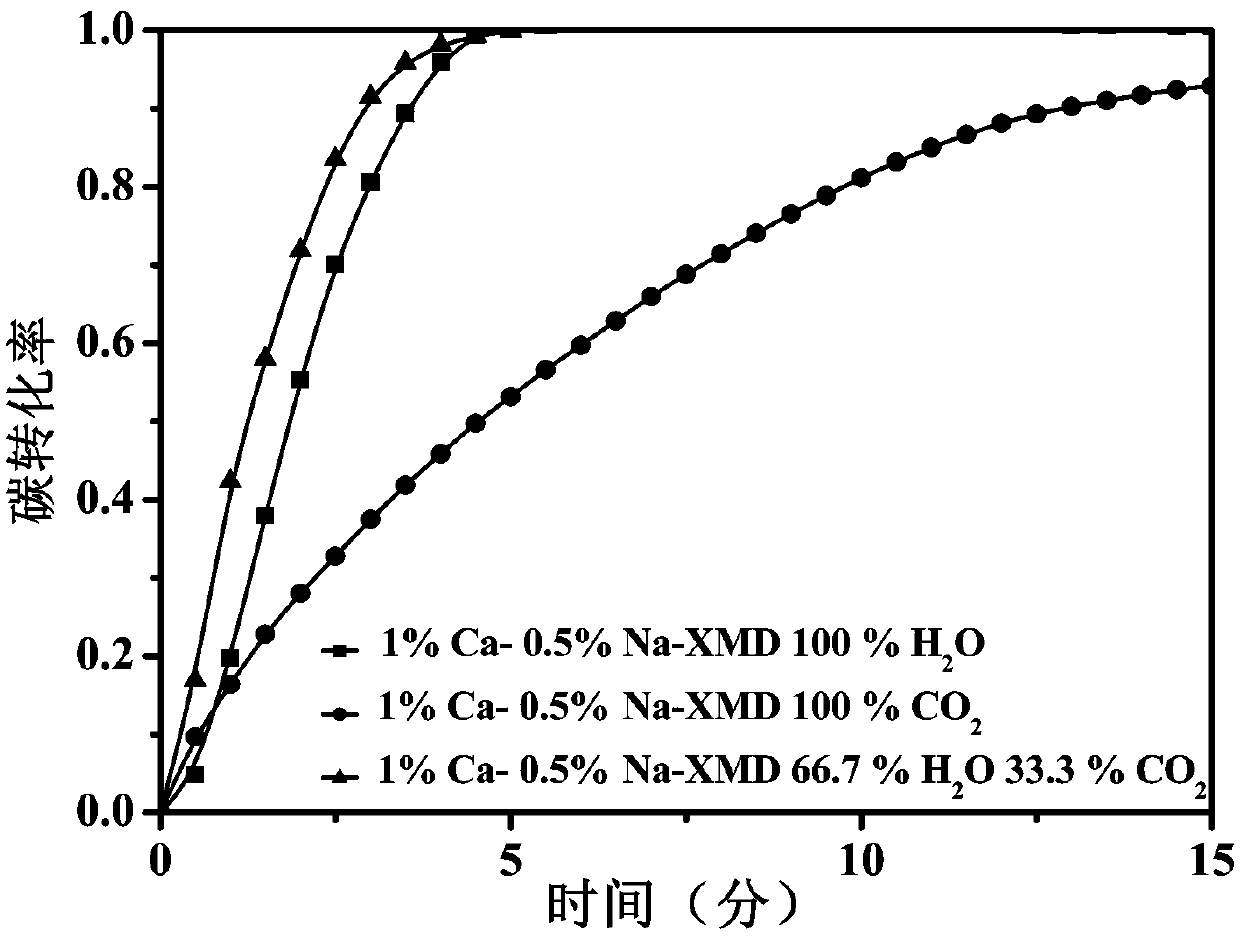

[0052] Example 2: Gasification experiment of deashed Ximeng coal.

[0053] According to the method of Example 1, the original coal sample of Ximeng was obtained by the quartering method (the coal type is a kind of lignite rich in vitrinite in Xilingol League, Inner Mongolia, and its ash composition is characterized by high clay minerals (>50%) ), after crushing, grinding, and sieving, coal samples with a particle size of less than 0.178mm were selected for experimentation. Deashed Ximeng coal (XMD) was prepared by acid washing and deashing, and then deashed Ximeng coal (1%Ca-0.5%Na-XMD) loaded with calcium and sodium was prepared by impregnation method (deashed Ximeng coal and calcium carbonate And the mass ratio of sodium carbonate is 100:2.5:1).

[0054] The gasification reactivity test of the deashed Ximeng coal loaded with calcium and sodium was also carried out on a multifunctional comprehensive thermal analyzer NETZSCHSTA 449 F3. The gasification experiment process and ...

Embodiment 3

[0058] Example 3: Gasification experiment of Ximeng raw coal.

[0059] The Ximeng raw coal with a particle size of less than 0.178mm in Example 2 is not subjected to deashing treatment, and directly adopts the impregnation method to make Ximeng coal (1%Ca-0.5%Na-XM) loaded with calcium and sodium (Ximeng coal and calcium carbonate And the mass ratio of sodium carbonate is 100:2.5:1). The gasification reactivity test was carried out on a multifunctional comprehensive thermal analyzer NETZSCH STA 449 F3. The gasification experiment process and the selected gasification agent ratio were the same as in Example 1, and the selected gasification temperature was 800°C.

[0060] Also calculate the carbon conversion rate and the average specific gasification reaction rate, and compare the strength of the synergistic effect produced by the gasification reaction between coal char and multiple gasification agents. The results are as follows Figure 4 with table 3.

[0061]

[0062] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com