Medium and low temperature gasification equipment for treating carbon-containing solid waste

A solid waste, low-temperature gasification technology, applied in gasification process, production of combustible gas, energy input, etc., can solve the problems of incomplete treatment of solid waste, narrow range of raw material applicability, unstable operation of equipment, etc. Achieve harmless transformation, avoid the generation of harmful components, and improve the effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 of the present application discloses a medium-low temperature gasification mechanism for treating carbonaceous solid waste.

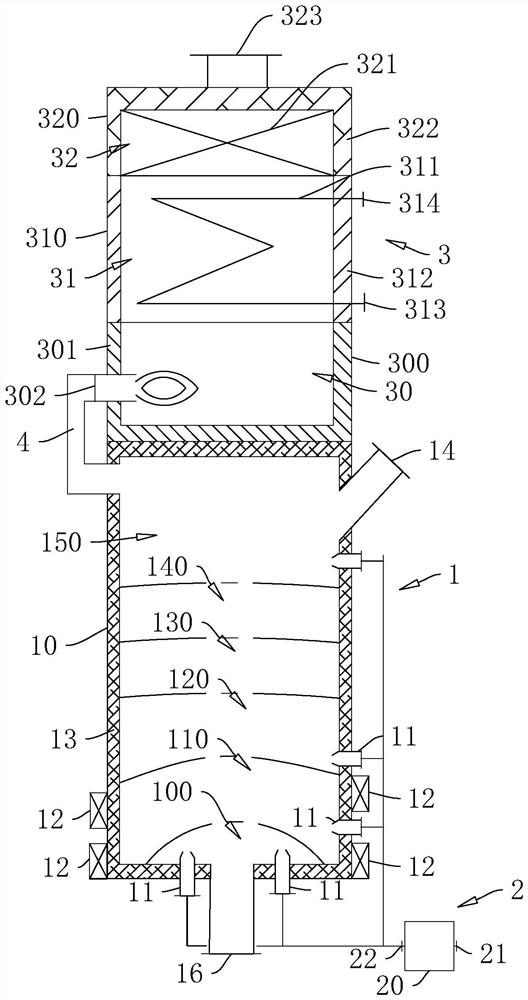

[0035] refer to figure 1 , a medium and low temperature gasification equipment for treating carbonaceous solid waste, refer to figure 1 , including gasification reactor 1 , negative oxygen ion generator 2 and connector 4 . In the embodiment of the present application, the incinerator 3 and the gasification reactor 1 are integrally arranged up and down, and the gasification reactor 1 is located below the incinerator 3 . The gasification reactor 1 and the incinerator 3 communicate with each other through the connecting piece 4, the negative oxygen ion generator 2 is used to generate negative oxygen ions and pass into the gasification reactor 1, and the gasification tail gas generated by the gasification of carbon-containing solid waste enters The incinerator 3 burns.

[0036] The gasification reactor 1 includes a gasification shell ...

Embodiment 2

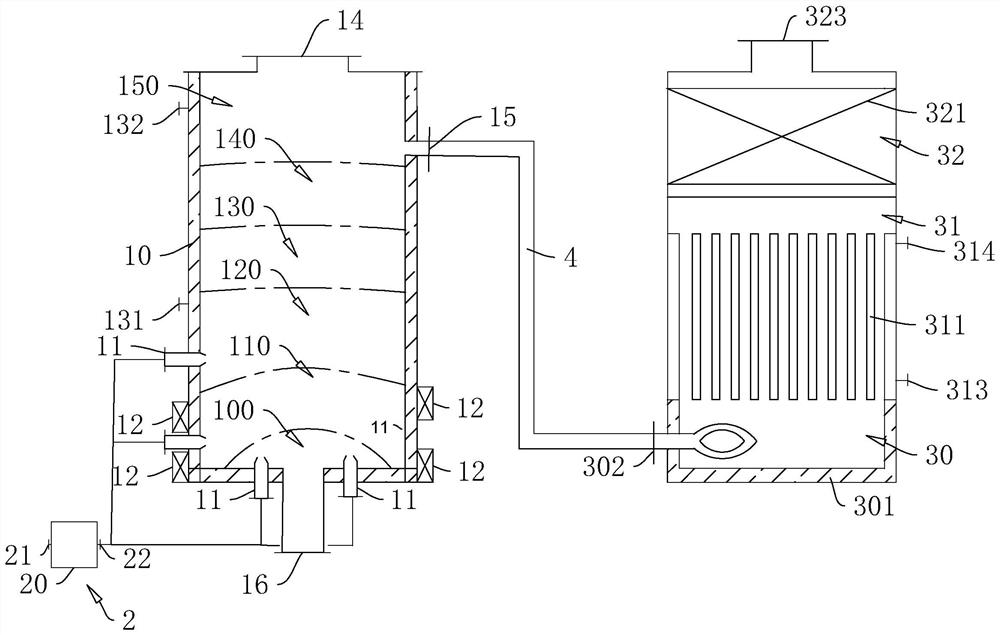

[0057] The difference from Example 1 is that the distribution of the gasification reactor 1 and the incinerator 3 is different, the materials of the gasification reactor 1 and the incinerator 3 are different, and the heat insulation methods are different, and the flue gas purification chamber 32 is the same as in the first embodiment. .

[0058] Specifically, refer to figure 2 , the gasification reactor 1 and the incineration section are arranged side by side. The gasification section is a vertical cylindrical structure with an inner diameter of 800mm and a height of 1200mm; the incineration section adopts a vertical square structure with an inner diameter of 1000mm×1000mm and a height of 1500mm.

[0059] The gasification casing 10 , the incineration chamber casing 300 , the waste heat recovery chamber casing 310 and the flue gas purification chamber casing 320 are all made of stainless steel 304. The heat insulation layer 13 of the gasification reactor is cooled by a water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com