Modification method of three-high coal gasification reaction activity

A reactive and coal gasification technology, which is applied in the gasification process, granular/powdered fuel gasification, and the manufacture of combustible gas, can solve the problems of low effective components of coal gas, low coal conversion rate, low volatile content, etc., and achieve improvement Gasification reactivity, broad application prospects, effect of reduced pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Select a typical "three-high coal" as raw material, grind and sieve to obtain an experimental sample with a particle size of 74-200 μm, which is recorded as raw coal;

[0019] 2) 20 g of the raw coal obtained in step 1) is taken and placed in a polytetrafluoroethylene beaker, and 400 ml of mass fraction of 68% concentrated nitric acid solution is added in the beaker, after stirring for 24 hours, the coal sample I is collected by filtration; then, the coal sample I Mix with 48% hydrofluoric acid solution at a ratio of 1:20, stir for 24 hours to ensure that the ash on the coal surface is completely removed, and filter to obtain coal sample II; then, wash repeatedly with 400ml of deionized water to ensure that the coal sample is completely removed HF solution in II; finally, dry coal sample II in a drying oven for 24 hours at a drying temperature of 120°C to obtain a modified coal sample.

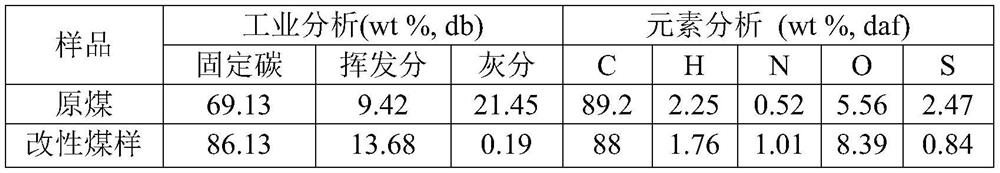

[0020] 3) Carry out industrial analysis and elemental analysis on raw coal and m...

Embodiment 2

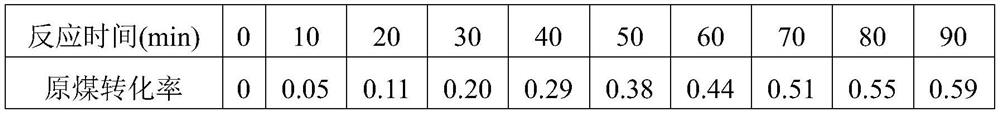

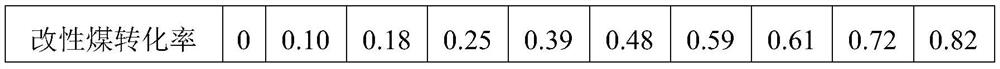

[0025] 1) Carry out the gasification experiment of pulverized coal in a thermogravimetric analyzer. First, place 10 ± 0.5 mg of raw coal and modified coal samples in a thermogravimetric crucible. 2 Heat up to 950°C at 20°C / min; after holding for 10 minutes, switch the gas to CO 2 , keep warm for 90min, stop the experiment; N 2 and CO 2 The flow rate is 50ml / min; record the instantaneous mass of pulverized coal during the reaction at 0, 10, 20, 30, 40, 50, 60, 70, 80, and 90 min, and then calculate the conversion rate of pulverized coal at different times.

[0026] Table 2 Conversion rate of samples during gasification experiment

[0027]

[0028]

[0029] It can be seen from the data in the table that the three-high coal modification method adopted in the patent of the present invention can significantly improve the gasification reaction activity of "three-high coal". When the reaction temperature is 950°C and the reaction time is 10 minutes, the conversion rate of raw...

Embodiment 3

[0031] 1) Carry out the gasification experiment of pulverized coal in a thermogravimetric analyzer. First, place 10 ± 0.5 mg of raw coal and modified coal samples in a thermogravimetric crucible. 2 Heat up to 1050°C at 20°C / min; after holding for 10 minutes, switch the gas to CO 2 , keep warm for 30min, stop the experiment; N 2 and CO 2 The flow rate is 50ml / min; record the instantaneous mass of pulverized coal during the reaction at 0, 2, 4, 6, 8, 10, 12, 14, 16, 18, and 20 minutes, and then calculate the conversion rate of pulverized coal at different times .

[0032] Table 3 Conversion rate of samples during gasification experiment

[0033] Response time (min) 0 10 20 30 40 50 60 70 80 90 Raw coal conversion rate 0 0.34 0.61 0.70 0.83 0.86 0.92 0.95 0.97 1.00 Conversion rate of modified coal 0 0.39 0.65 0.78 0.92 0.94 0.96 1.00 1.00 1.00

[0034] It can be seen from the data in the table that the three-high coal modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| escape rate | aaaaa | aaaaa |

| escape rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com