A method for catalytic gasification and methane enrichment of gasification coke

A technology of methanation and coke particles, which is applied in gasification process, coke oven, and combustible gas production, can solve the problems of high hydrogen cost, large equipment investment, and low methane yield, and achieve good gasification reaction activity and low Catalyst cost, effect of high methanation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

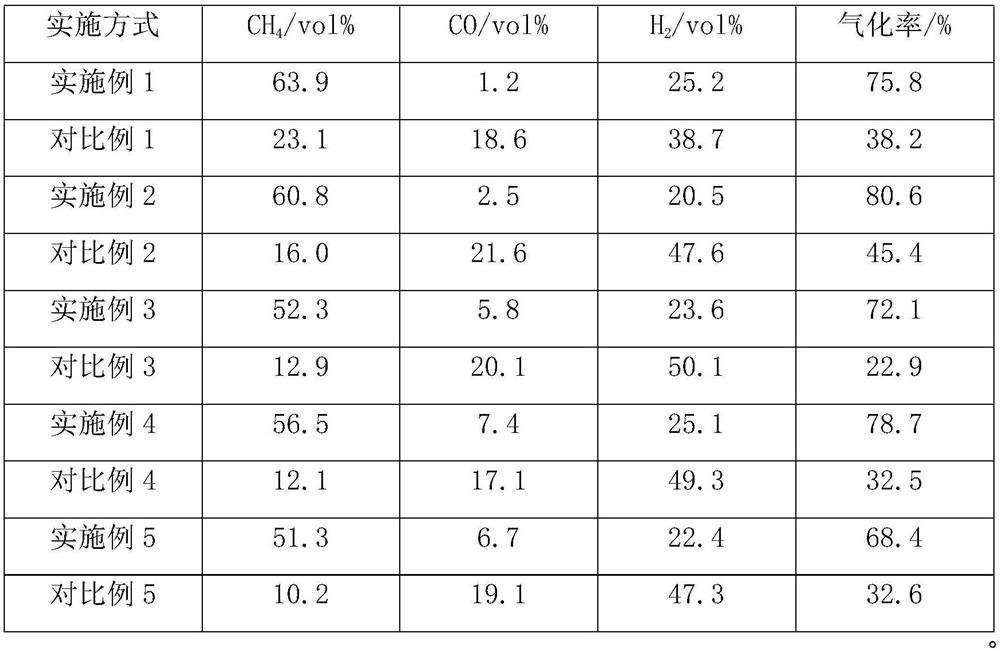

Examples

Embodiment 1

[0023] Dry-grind laterite nickel ore with initial Ni and Fe contents of 1.34wt% and 30.2wt%, respectively, to obtain mineral powder with a particle size of ≤3mm, and add 15wt% of Na to the crushed mineral powder. 2 CO 3 , After mixing uniformly, in a stirred reactor at 800 ℃, water gas (gas composition is H 2 50vol%, CO 40vol%, CO 2 9vol%, the other 1vol%) was reduced and burned for 120min under the condition of 160L / (g·h) space velocity to prepare the required additives.

[0024] After that, the lignite, gas coal, and fat coal are respectively sent to the crusher for preliminary crushing. After crushing, additives are added for mixing. The mass ratio of lignite, gas coal, fat coal and additives is 3:5:1:0.25. After mixing, enter the counterattack The crusher is used for crushing and mixing, and the content of coal with a size of less than 3 mm in the crushed coal reaches 93 wt%.

[0025] The crushed coal is tamped to form a cylindrical coal cake, and then the coal cake is put int...

Embodiment 2

[0030] The initial Ni and Fe content of 1.02wt% and 29.8wt% laterite nickel ore were dry-grinded to obtain mineral powder with a particle size of ≤3mm, and 10wt% Na was added to the crushed mineral powder. 2 CO 3 And 5wt% of CaO, mixed uniformly, in a stirred reactor at 1000 ℃, water gas (gas composition is H 2 50vol%, CO 40vol%, CO 2 9 vol%, the other 1 vol%) was reduced and burned for 80 minutes at a space velocity of 120L / (g·h) to prepare the required additives.

[0031] After that, the lignite, gas coal, and fat coal are respectively sent to the crusher for preliminary crushing. After crushing, additives are added for mixing. The mass ratio of lignite, gas coal, fat coal and additives is 1:5:1:0.25. After mixing, enter the counterattack The crusher is used for crushing and mixing, and the content of coal with a size of less than 3mm in the crushed coal reaches 95wt%.

[0032] The crushed coal is tamped to form a cylindrical coal cake, and then the coal cake is put into a high-...

Embodiment 3

[0037] The laterite nickel ore with initial Ni and Fe contents of 1.98wt% and 31.2wt%, respectively, was dry-milled to obtain mineral powder with a particle size of ≤3mm. Add 20wt% CaO to the crushed mineral powder, and mix it evenly. In a stirred reactor at 900℃, coke oven gas (gas composition is CH 4 25.3vol%, H 2 60.5vol%, CO 6.2vol%, C 2+ Unsaturated hydrocarbon 3.0vol%, CO 2 2.0vol%, O 2 0.5 vol%, other 2.5 vol%) at a space velocity of 140L / (g·h), reduced and burned for 90 minutes to prepare the required additives.

[0038] After that, the lignite, gas coal, and fat coal are respectively sent to the crusher for preliminary crushing. After crushing, additives are added for mixing. The mass ratio of lignite, gas coal, fat coal and additives is 3:2:1:0.25. After mixing, enter the counterattack The crusher is used for crushing and mixing, and the content of coal with a size of less than 3mm in the crushed coal reaches 91wt%.

[0039] The crushed coal is tamped to form a cylind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com