Waste heat recycling method and device of full-hydrogen hood-type annealing furnace

A bell-type annealing furnace and waste heat recovery technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve problems such as waste of energy, achieve the effects of increasing heat transfer rate, increasing cooling rate, and increasing heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

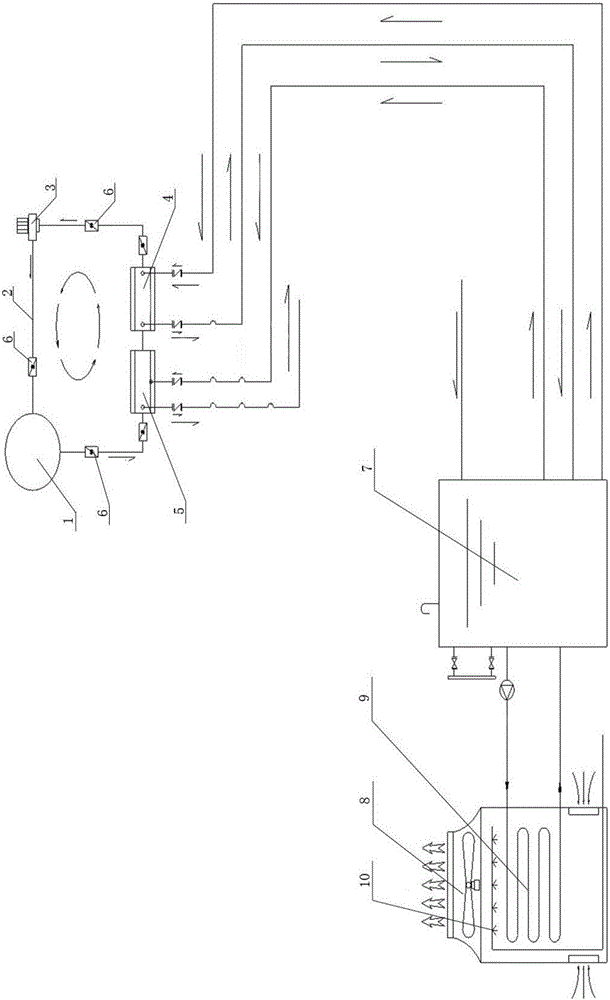

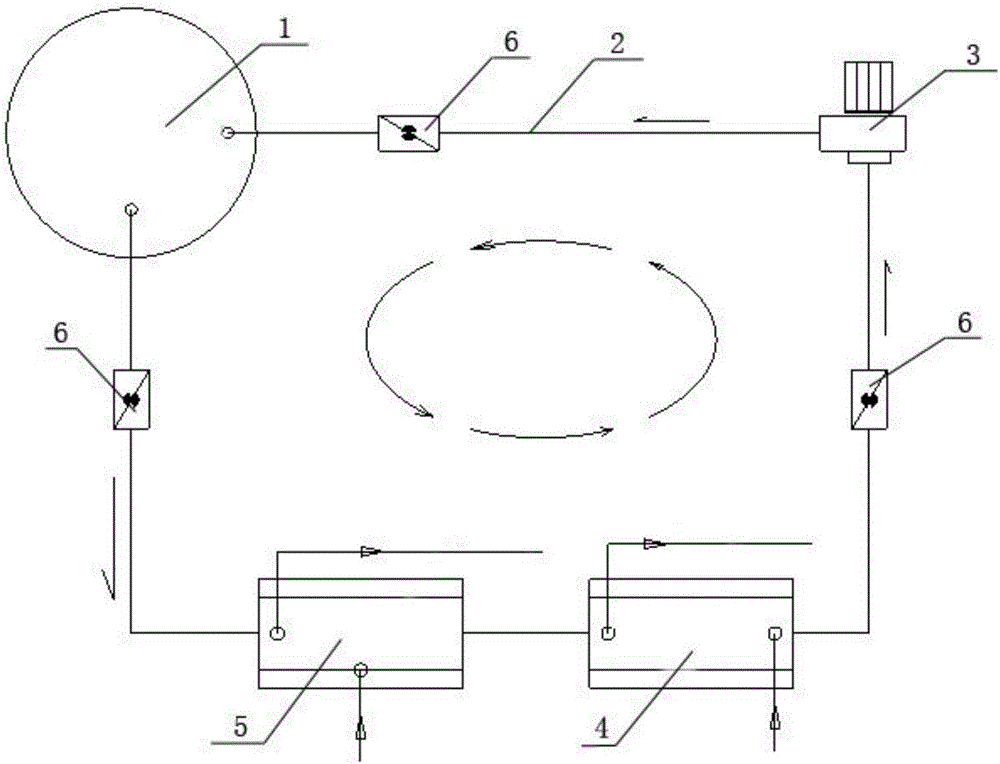

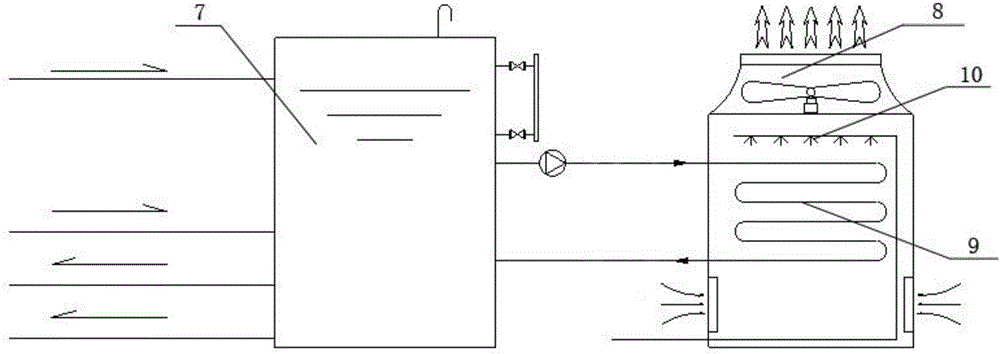

[0020] After the steel strip is kept warm in the full hydrogen bell annealing furnace, open the high-temperature gas butterfly valve between the full hydrogen bell annealing furnace inner cover and the steam waste heat boiler, and the high temperature hydrogen in the full hydrogen bell annealing furnace inner cover enters the steam waste heat Boiler, steam waste heat boiler set steam pressure 0.6MPa, saturation temperature 150°C, the generated steam is sent to the demand unit through the steam heat supply main pipe; the temperature of high-temperature hydrogen passing through the steam waste heat boiler is reduced to 180°C, and then enters the hot water waste heat boiler For further cooling, the water in the hot water waste heat boiler absorbs the heat of high-temperature hydrogen and sends it to the water tank through the outlet pipe of the hot water waste heat boiler; the high-temperature gas butterfly valve between the hot water waste heat boiler and the magnetic drive non-le...

Embodiment 2

[0022] After the steel strip is kept warm in the full hydrogen bell annealing furnace, open the high-temperature gas butterfly valve between the full hydrogen bell annealing furnace inner cover and the steam waste heat boiler, and the high temperature hydrogen in the full hydrogen bell annealing furnace inner cover enters the steam waste heat Boiler, steam waste heat boiler set steam pressure 1.0MPa, saturation temperature 180°C, the generated steam is sent to the demand unit through the steam heating main pipe; the temperature of high-temperature hydrogen passing through the steam waste heat boiler is reduced to 220°C, and then enters the hot water waste heat boiler For further cooling, the water in the hot water waste heat boiler absorbs the heat of high-temperature hydrogen and sends it to the water tank through the outlet pipe of the hot water waste heat boiler; the high-temperature gas butterfly valve between the hot water waste heat boiler and the magnetic drive non-leakag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com