High-strength and tissue stable nickel-base single crystal superalloy and preparation method thereof

A nickel-based single crystal, superalloy technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of high cost and unstable microstructure, and achieve low cost and excellent high temperature performance. and single crystal process performance, the effect of low Ru content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

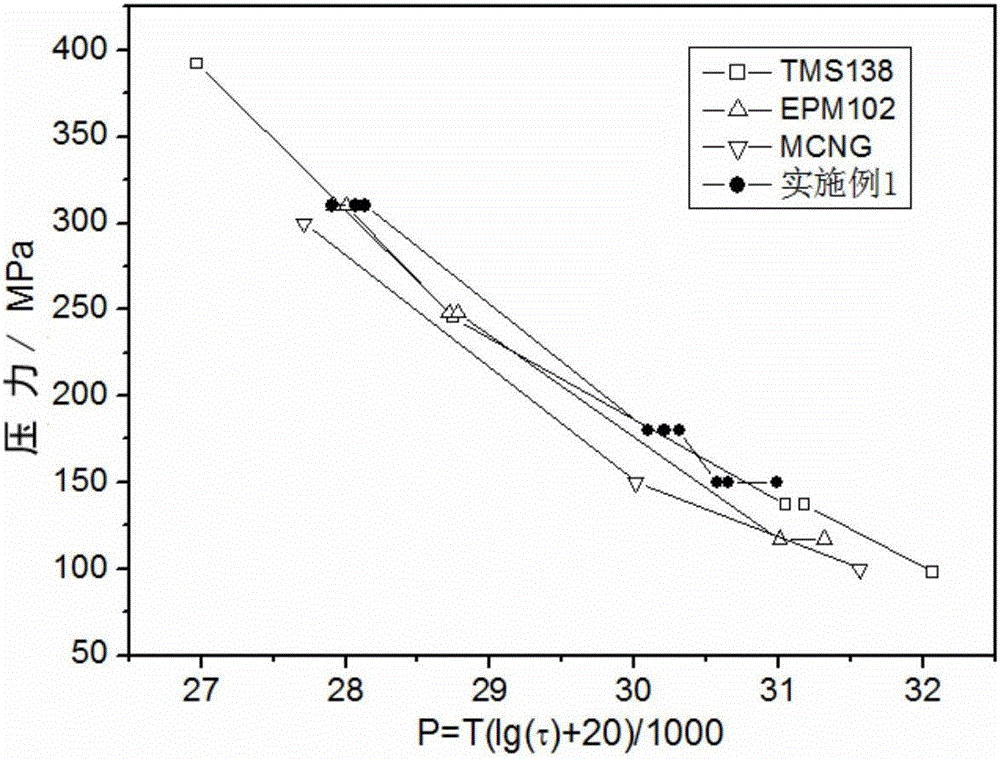

[0048] The specific composition of the alloy of the present invention is shown in Table 1. For the convenience of comparison, the chemical composition of CMSX-4 and CMSX-10 is also listed in Table 1.

[0049] Table 1 The present embodiment and the chemical composition (wt%) of comparative alloy CMSX-10 and EPM102

[0050]

[0051] After batching and vacuum induction melting according to the alloy composition, it is cast into a master alloy ingot with a size of φ80×500mm, then polished to remove scale, and cut into suitable blocks for preparing single crystal rods.

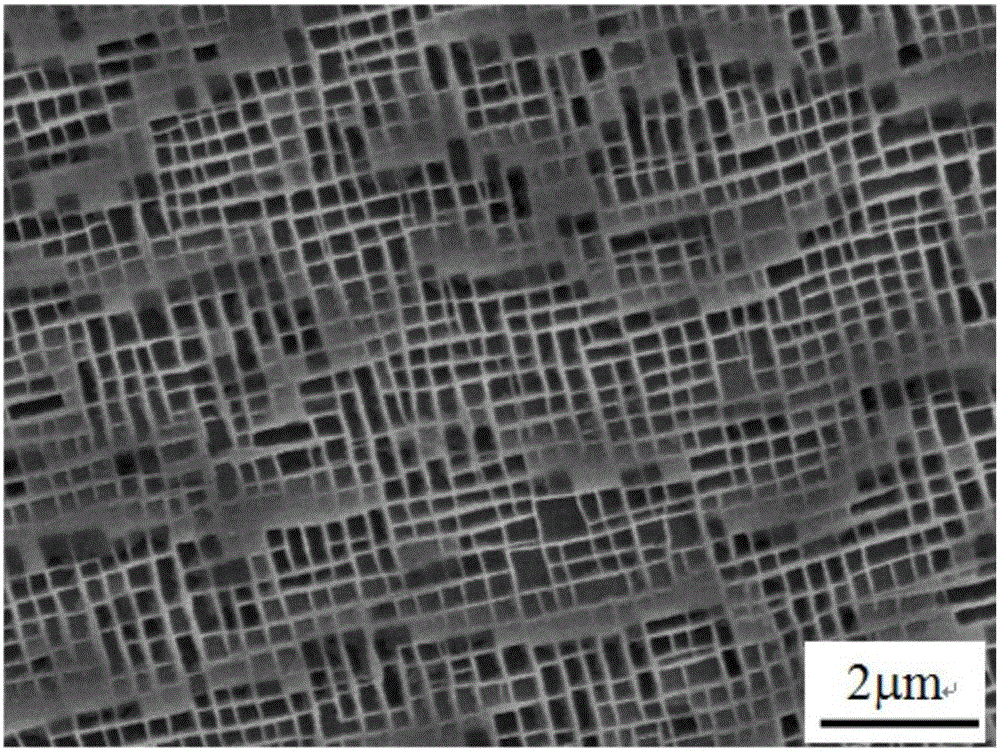

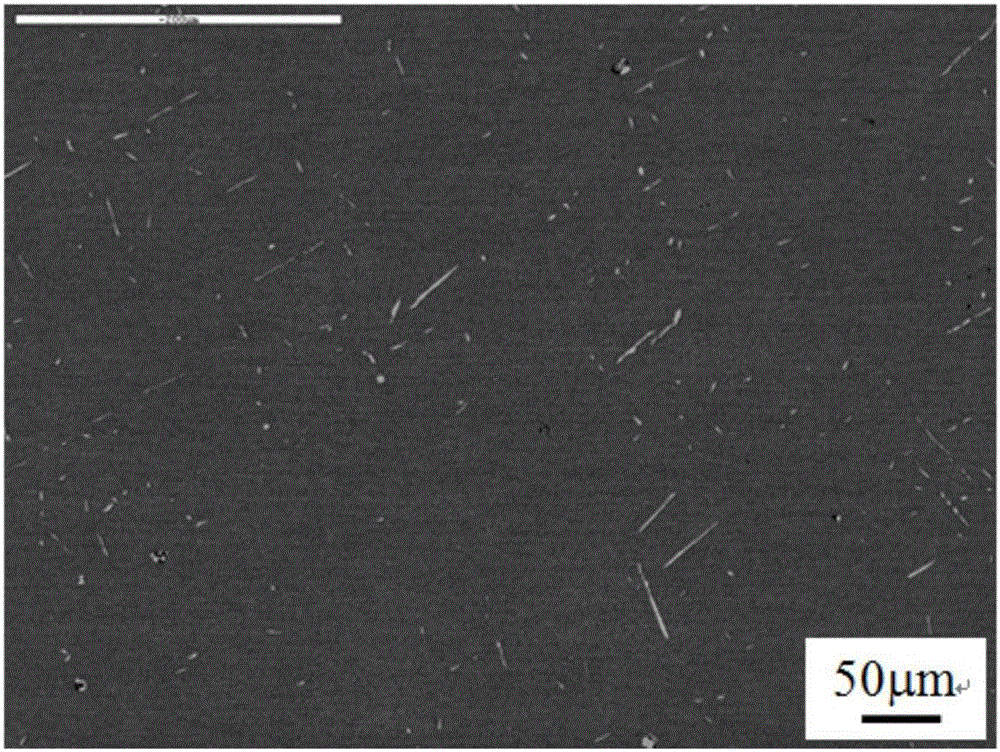

[0052] The single crystal rod is prepared in a directional solidification furnace by the spiral crystal selection method. The temperature gradient of the single crystal growth furnace is 60K / cm, the pouring temperature is 1550°C, and the shell temperature is kept consistent with the pouring temperature; after standing for 10 minutes, pull with a predetermined single crystal growth rate of 5mm / min to prepare a si...

Embodiment 2

[0066] The difference from Example 1 is that the composition of the alloy in this example is shown in Table 4, and the composition of Example 1 is also listed in the table for the convenience of comparison.

[0067] After batching and vacuum induction melting according to the alloy composition, it is cast into a master alloy ingot with a size of φ80×500mm, then polished to remove scale, and cut into suitable blocks for preparing single crystal rods.

[0068] The single crystal rod is prepared in a directional solidification furnace by the spiral crystal selection method. The temperature gradient of the single crystal growth furnace is 60K / cm, the pouring temperature is 1550°C, and the shell temperature is kept consistent with the pouring temperature; after standing for 10 minutes, pull with a predetermined single crystal growth rate of 5mm / min to prepare a single crystal rod.

[0069] Table 4 present embodiment and embodiment 1 and EPM102 alloy chemical composition (wt%)

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com