Electrostatic spinning device with porous nozzle

A technology of electrospinning and nozzles, which is applied in textile and papermaking, filament/thread forming, fiber processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

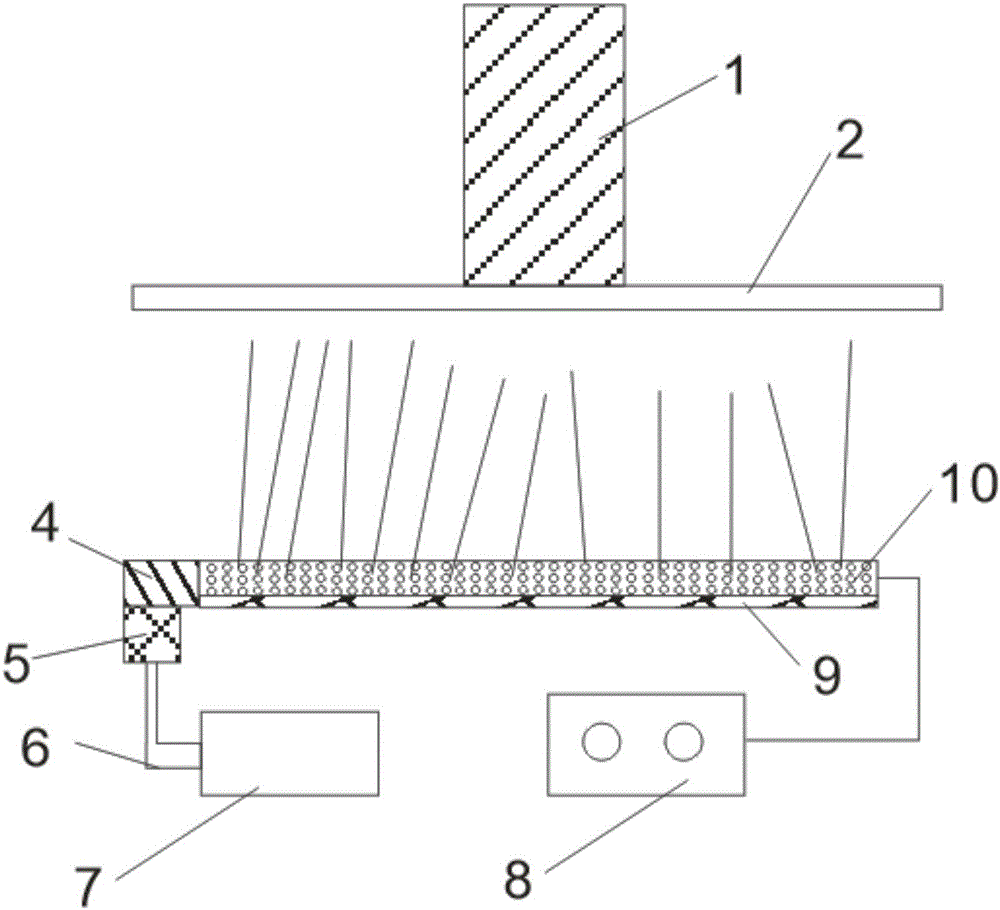

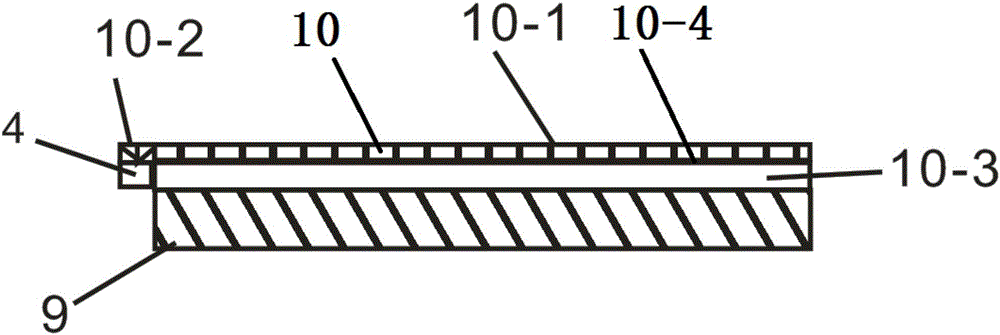

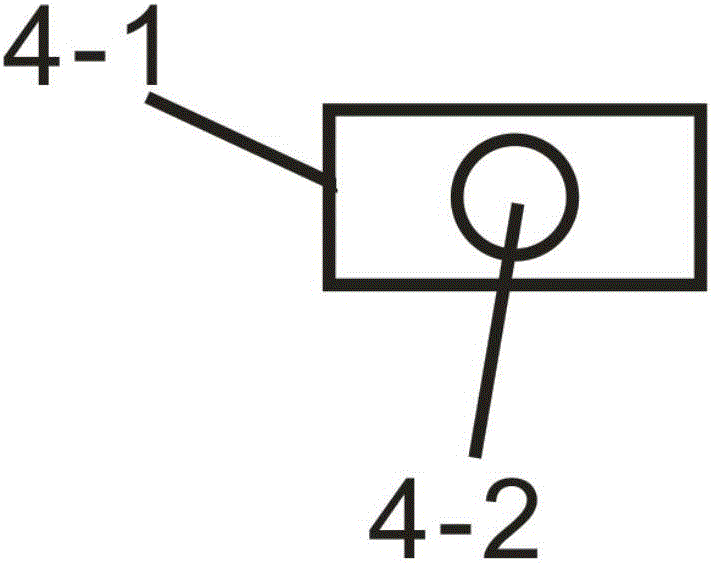

[0031] refer to Figure 1-Figure 4 , the electrospinning device with the porous nozzle of the present embodiment comprises the spinning receiving plate 2 for receiving the nanofiber, the porous nozzle spinneret for ejecting the nanofiber, the spinning solution storage for storing the spinning solution. A liquid container 7, a pressure pump 5 for delivering the spinning liquid to the spinneret of the multi-hole nozzle, and a high-voltage generator 8 for providing high-voltage static electricity for the spinneret of the multi-hole nozzle. Described porous nozzle spinneret comprises the spinneret container 10 that is made of insulating material, and the top of spinneret container 10 is provided with a plurality of spinneret holes that communicate with the inner chamber 10-3 of spinneret container 10, and each spinneret Metal nozzles 10-1 are arranged in the hole, and all metal nozzles 10-1 are connected to each other and connected to the high-pressure generator 8; both ends of th...

Embodiment 2

[0042] see Figure 5-Figure 6 , The difference between this embodiment and Embodiment 1 is that in this embodiment, the fiber collection unit is a circular collection mechanism, which consists of two transmission rollers 3 and surrounding the transmission roller 3 The loop collection belt 11 constitutes.

[0043] The spinning container 10 is a cylindrical container.

Embodiment 3

[0045] see Figure 7 and Figure 8 , The difference between this embodiment and Embodiment 1 is that in this embodiment, the fiber collection unit is a one-way transmission and collection mechanism, and the one-way transmission and collection mechanism is composed of a driving roller 3 and a spinning receiving plate 2 The one-way collection belt 12 that conveys in one direction below constitutes.

[0046] The spinning container 10 is a square container, and the spinning hole is a triangular hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com