Composite steel plate and manufacturing method thereof

A technology of composite steel plate and steel plate, applied in the direction of building materials, etc., can solve the problem of not being able to fundamentally solve the problem of bearing capacity of steel beams, the impact of carbon fiber cloth reinforcement on the durability of steel structures, and the inability to greatly improve the bearing capacity of steel beams, etc. Achieving good corrosion resistance, light weight and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

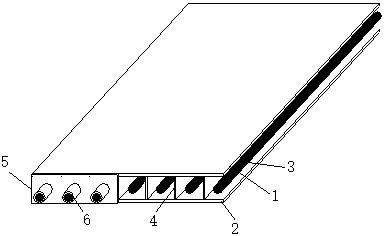

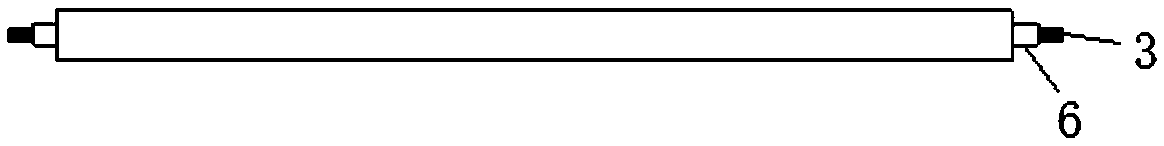

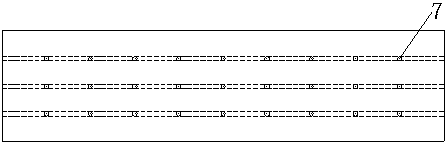

[0029] Such as figure 1 As shown, the composite steel plate of the present invention includes a sandwich steel plate, fiber tendons 3, anchors 6, backing plate 5; the sandwich steel plate includes an upper panel 1 and a lower panel 2, and the equidistant distance The web 4 is arranged; the fiber reinforcement 3 passes through the sandwich steel plate, and the two ends are fixed by the anchor 6 and the backing plate 5; this embodiment adopts carbon fiber reinforcement, and the carbon fiber reinforcement is divided into two types: ribbed and non-ribbed, with a diameter of ≥ 3mm , the present embodiment uses a carbon fiber bar with a diameter of 3mm; the sandwich steel plate adopts a 3mm thick stainless steel plate, and the anchorage 6 is a tapered anchorage.

[0030] The method for making composite steel plate provided by the invention comprises the following steps: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com