Self-adaptive intelligent control system of ventilator

An intelligent control system and ventilator technology, applied in pump control, mine/tunnel ventilation, mechanical equipment, etc., can solve the problems of not being able to ensure that the working face gas does not exceed the limit, waste electric energy, etc., to avoid gas over-limit accidents, Overcome the effect of high energy consumption, safe and comfortable working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

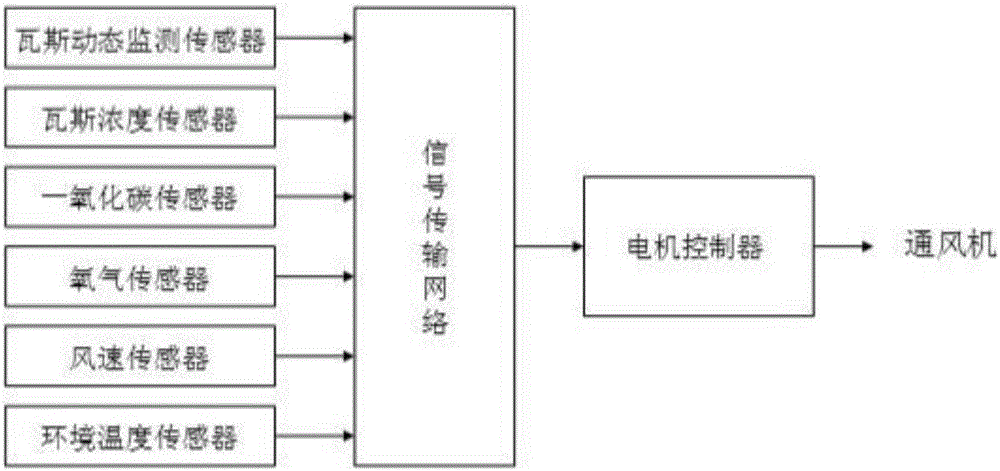

[0017] Embodiment 1: The ventilator self-adaptive intelligent control system is composed of three parts such as a mine environment parameter monitoring unit, a signal transmission network and a motor control unit. The mine environment parameter monitoring unit is connected to the input end of the signal transmission network, and the output end of the signal transmission network It is connected with the motor control unit, and the output terminal of the motor control unit is connected with the fan;

[0018] The mine environment parameter monitoring unit includes a gas dynamic monitoring sensor, a gas concentration sensor, a wind speed sensor, a carbon monoxide sensor, an oxygen sensor and an ambient temperature sensor;

[0019] The signal transmission network can have multiple methods, including wireless transmission, CAN bus transmission and industrial Ethernet transmission, and can also combine multiple communication networks to complete wired and wireless transmission; the si...

Embodiment 2

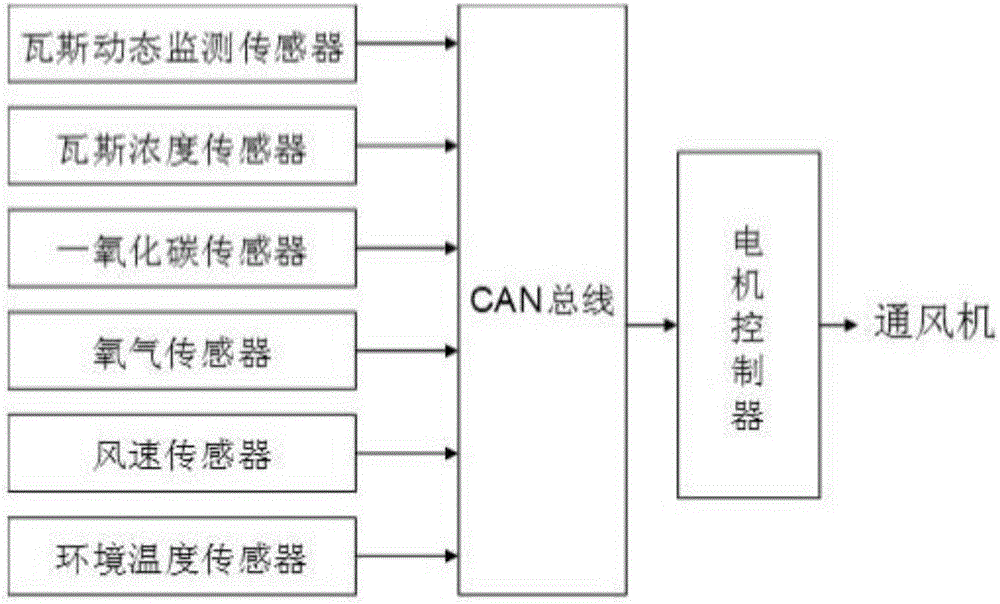

[0030] Example 2: In figure 2 Among them, the gas dynamic monitoring sensor, gas concentration sensor, wind speed sensor, carbon monoxide sensor, oxygen sensor and ambient temperature sensor in the mine environmental parameter monitoring unit in the ventilator adaptive intelligent control system directly transmit the environmental monitoring signal to It is transmitted to the fan motor controller, and the fan motor controller outputs frequency modulation power supply to the fan motor, controls the speed of the fan, and adjusts reasonable ventilation parameters. Others are the same as in Example 1.

Embodiment 3

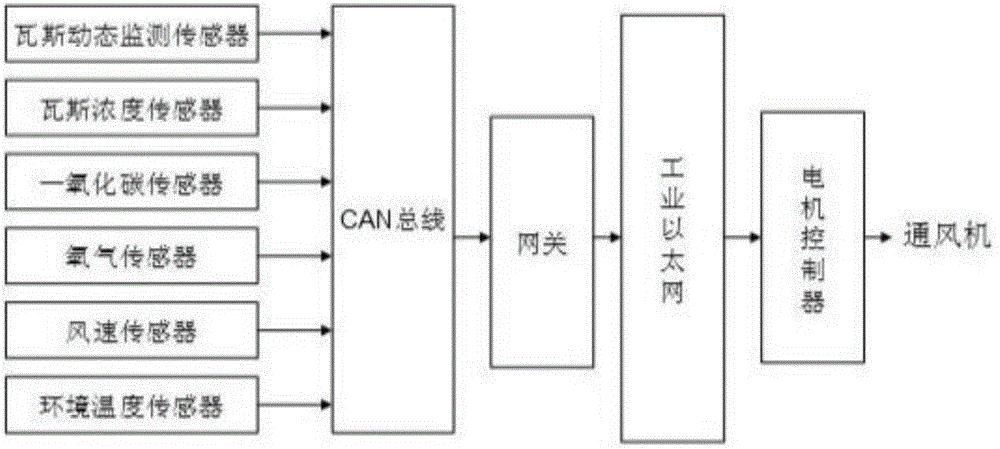

[0031] Example 3, in image 3 Among them, the gas dynamic monitoring sensor, gas concentration sensor, wind speed sensor, carbon monoxide sensor, oxygen sensor and ambient temperature sensor in the mine environmental parameter monitoring unit in the ventilator adaptive intelligent control system transmit the environmental monitoring signal through CAN bus communication. To the gateway, the monitoring signal is transmitted to the industrial Ethernet through the gateway, and then the signal is transmitted to the fan motor controller through the industrial Ethernet. The fan motor controller outputs frequency modulation power supply to the fan motor, controls the speed of the fan, and adjusts reasonably ventilation parameters. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com