Pilot hydraulic control system based on multi-shuttle-valve set and drilling machine

A hydraulic control system and pilot control valve technology, applied in the field of hydraulic machinery, can solve the problems of large space occupation, many assembly pipelines, and difficult processing, and achieve the effects of reducing hydraulic connections, reliable idle speed control, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

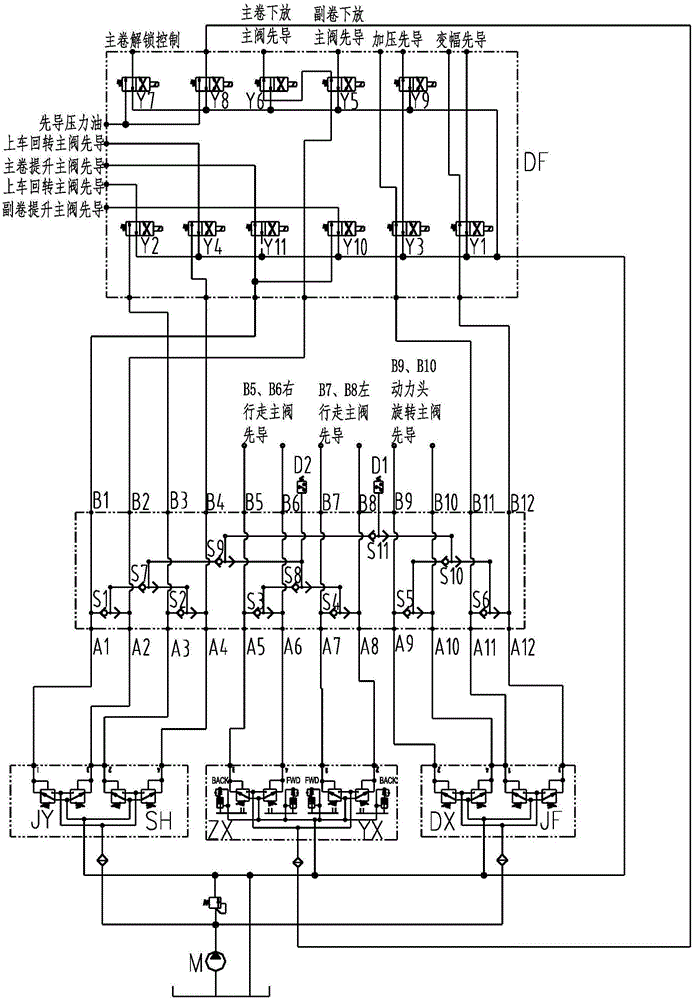

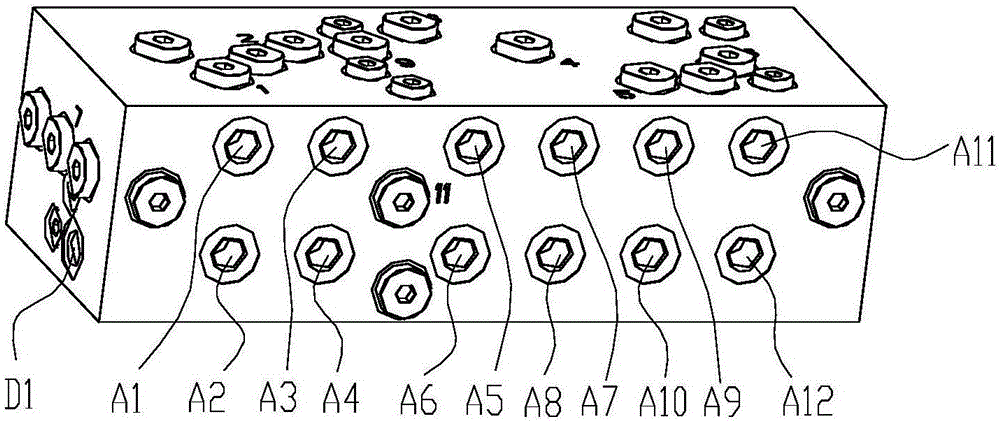

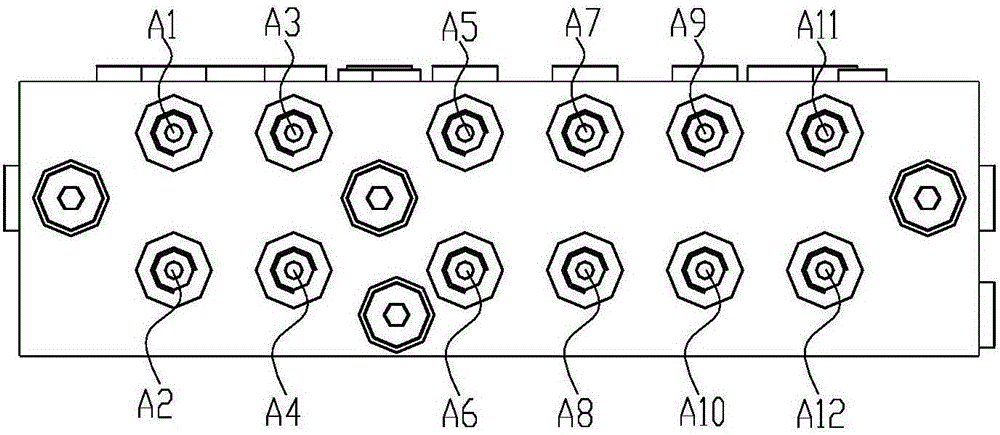

[0054] figure 1 It is a principle diagram of the pilot hydraulic control system using eleven shuttle valve groups in the pilot hydraulic control system based on multiple shuttle valve groups proposed in Embodiment 1 of the present invention. figure 2 for figure 1 Schematic diagram of the three-dimensional structure of the eleven-connected shuttle valve group. image 3 for figure 2 main view. Figure 4 for figure 2 back view. Figure 5 for figure 2 left view of .

[0055] see Figure 1 to Figure 5 , the pilot hydraulic control system based on the multi-connected shuttle valve group includes the hydraulic pump M connected to the oil tank, the winch pilot control valve JY connected to the hydraulic pump, the turning pilot control valve SH of the boarding car, the pilot control valve DX of the power head rotation, and the Pressure variable amplitude pilot control valve JF, left travel pilot control valve ZX, right travel pilot control valve YX, eleven-connected shuttle...

Embodiment 2

[0062] Figure 6 It is a schematic diagram of the pilot hydraulic control system using five shuttle valve groups in the pilot hydraulic control system based on multiple shuttle valve groups proposed in Embodiment 2 of the present invention. Figure 7 for Figure 6 The front view of the five-way shuttle valve group. Figure 8 for Figure 6 back view. Figure 9 for Figure 6 left view of . Figure 10 for Figure 6 right view of .

[0063] see Figure 6 to Figure 10 The difference between the second embodiment and the first embodiment lies in that: the boarding rotary pilot control valve SH, the left travel pilot control valve ZX, and the right travel pilot control valve YX are directly connected to the solenoid valve group DF.

[0064] The second embodiment differs from the first embodiment in that: the multi-connected shuttle valve group is a five-connected shuttle valve group.

[0065] The five-connected shuttle valve group includes a first oil inlet A1', a second oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com