Furnace arch linked adjusting incinerating device and method based on heat value of garbage

An incineration device and waste technology, applied in the combustion method, incinerator, combustion type and other directions, can solve the problems of unstable combustion of low calorific value waste, large fluctuation of combustion efficiency, fluctuation of waste calorific value, etc., to reduce the risk of downtime and Maintenance costs, improved drying capacity, lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

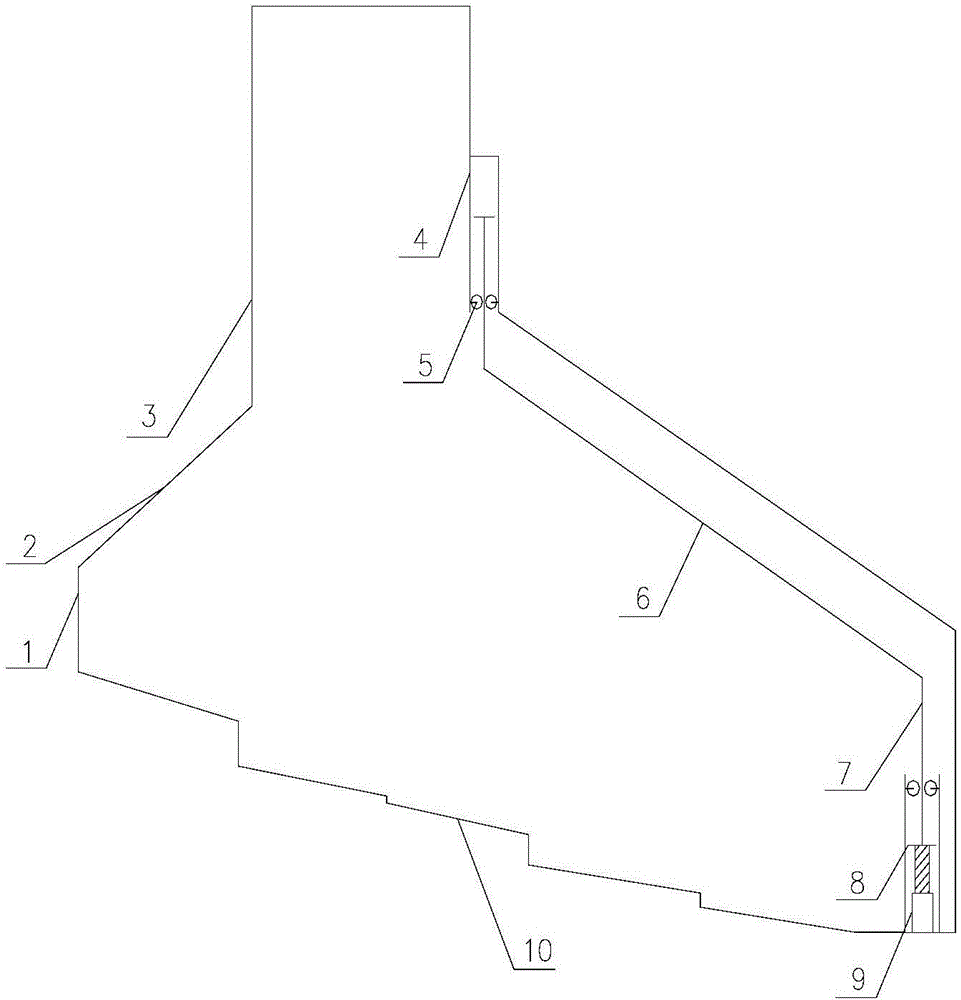

[0042] Such as figure 1 As shown, a furnace arch linkage adjustment high-efficiency incineration device based on the calorific value of waste, including a mechanical grate furnace, a movable rear arch radiant panel system, a control system, temperature sensors distributed in the mechanical grate furnace, and a steam drum The pressure sensor and flow sensor at the place, the mechanical grate furnace is mainly surrounded by the incineration furnace, the mechanical grate 10, the flue 3, the front arch 2, the garbage inlet 1, the slagging outlet and the left and right side walls. The entrance 1 is the interface where the garbage to be incinerated enters the furnace, the front arch 2 is a section of the inclined furnace wall, and the flue 3 is the passage where the volatile matter and fly ash separated from the garbage mix with the primary air and secondary air and rise. The movable rear arch radiant panel system is arranged at the rear arch in the mechanical grate furnace, and the...

Embodiment 2

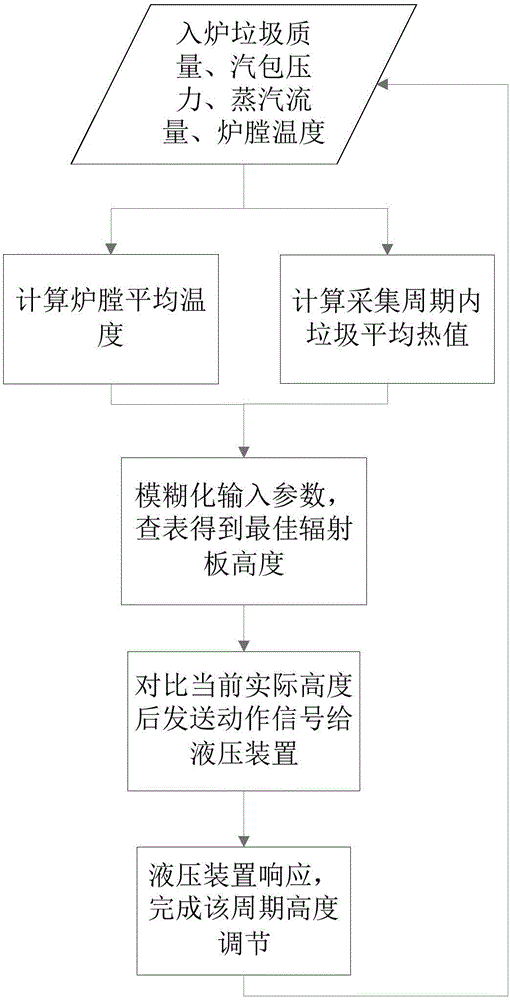

[0047] Such as figure 2 As shown, a furnace arch linkage adjustment high-efficiency incineration method based on the furnace arch linkage adjustment high-efficiency incineration device includes the steps:

[0048] (1) The garbage enters the top of the grate through the feeder of the garbage inlet 1, and the primary air is blown into the furnace from the grate air chamber;

[0049] (2) Collect operating parameters such as average steam drum pressure and average steam flow rate, and measure furnace temperature T in real time 1 , Furnace arch position temperature T 2 , calculate the average furnace temperature in the acquisition period according to the change of furnace temperature with time;

[0050] (3) Real-time measurement of data such as steam drum pressure p, steam drum steam flow rate D, and furnace garbage quality M, etc., according to the average steam drum pressure, average steam flow rate, and furnace garbage quality, use the positive balance method to reverse the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com