Solid energy storage module and electric heating solid energy storage device

An energy storage module and energy storage device technology, applied in electric heating devices, heat storage equipment, ohmic resistance heating, etc., can solve the problems of complex structure, short life of electric heating tubes, troublesome maintenance and replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

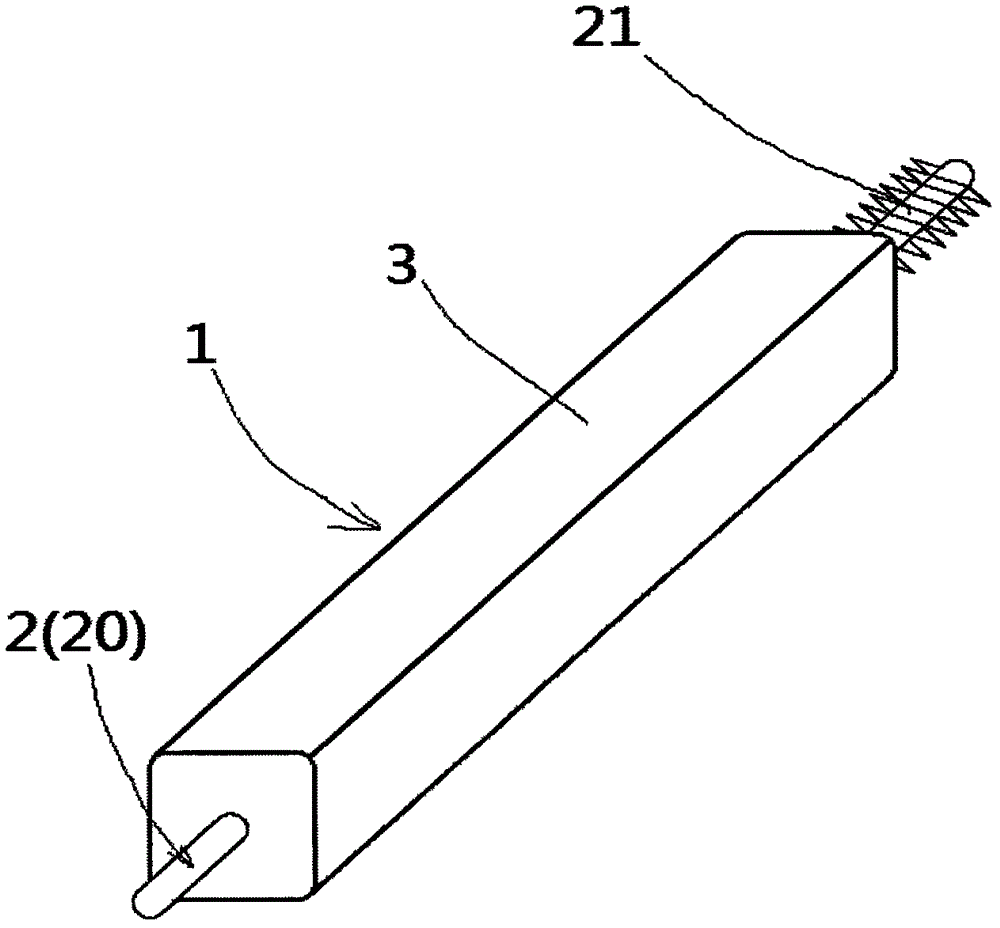

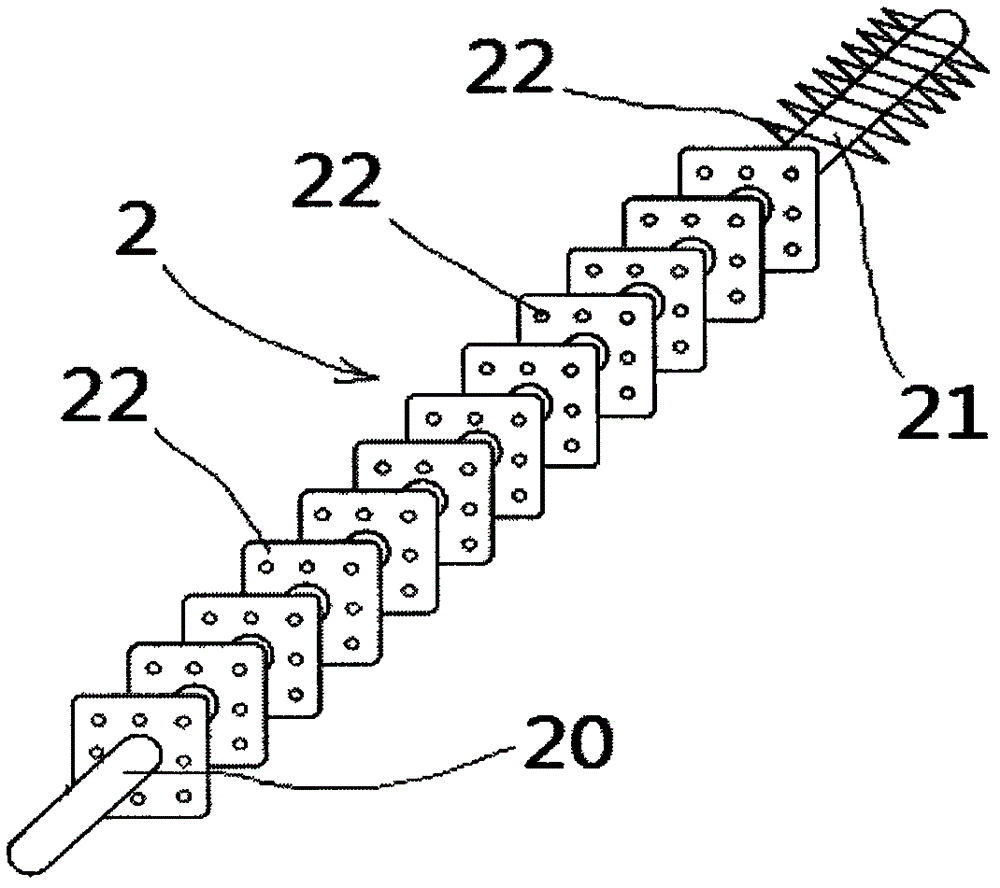

[0052] Such as figure 1 with figure 2 As shown, a solid energy storage module includes a solid energy storage module 1, the solid energy storage module 1 includes a heat pipe 2 and an energy storage material body 3 wrapped outside the heat pipe 2, and the heat pipe 2 runs through the energy storage material body 3, and the heat-absorbing section 20 and the heat-dissipating section 21 at both ends of the heat pipe 2 extend out of the body of the energy storage material body 3, and a number of heat-conducting fins are arranged on the outer surface of the heat pipe 2 except the heat-absorbing section 20 twenty two. The heat conduction fins 22 on the heat dissipation section 21 are different in shape from the heat conduction fins 22 in the energy storage material body 3 , one is an annular heat conduction fin, and the other is a square heat conduction fin with several through holes. The heat pipe used is a special heat pipe. The heat transfer medium inside the heat pipe is made...

Embodiment 2

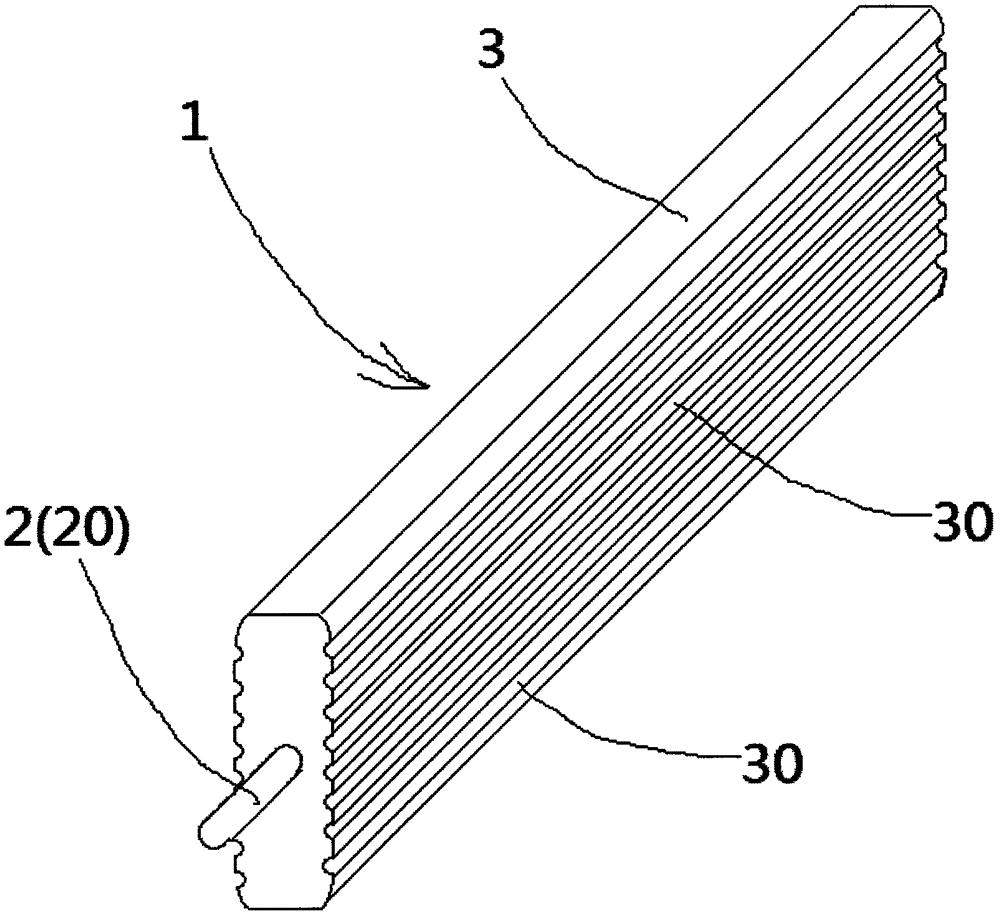

[0069] Such as figure 1 with image 3 As shown, the solid energy storage module 1 includes a heat pipe 2 and an energy storage material body 3 wrapped outside the heat pipe 2. The heat pipe 2 runs through the body of the energy storage material body 3, and only the heat absorbing section 20 extends out of the energy storage material. Outside the body of the body 3, a number of heat conducting fins 22 are arranged on the outer surface of the heat pipe 2 except the heat absorbing section 20, and a number of grooves 30 for air circulation are arranged on the outer surface of the energy storage material body 3. Others are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0071] Such as figure 1 , figure 2 with Figure 4 As shown, an electrothermal solid energy storage device 11 includes the solid energy storage module 1 shown in Embodiment 1, the induction coil 4, the high-frequency current generation and control device 5, the outer heat preservation shell 6, the temperature sensor 7, and several The solid energy storage modules 1 are regularly stacked in the outer heat preservation shell 6, and the heat absorption sections 20 of each solid energy storage module 1 are arranged on the same side, and each heat absorption section 20 is covered with an induction coil 4 , and all the induction coils 4 and the temperature sensors 7 are connected to the high-frequency current generation and control device 5, correspondingly, the heat dissipation section 21 is located on the other side, and forms a heat dissipation zone with the inner side of the outer heat preservation shell 6 Cavity 8, and several air outlets 80 and return air outlets 81 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com