High-sensitivity food colorant detection method

A high-sensitivity, high-sensitivity detection method technology, applied in the detection of trace food colorants, in the field of food colorant detection, can solve the problems of complex operation, time-consuming, low sensitivity of near-infrared spectroscopy analysis technology, etc., to achieve simple detection process, The effect of fast detection speed and good Raman enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

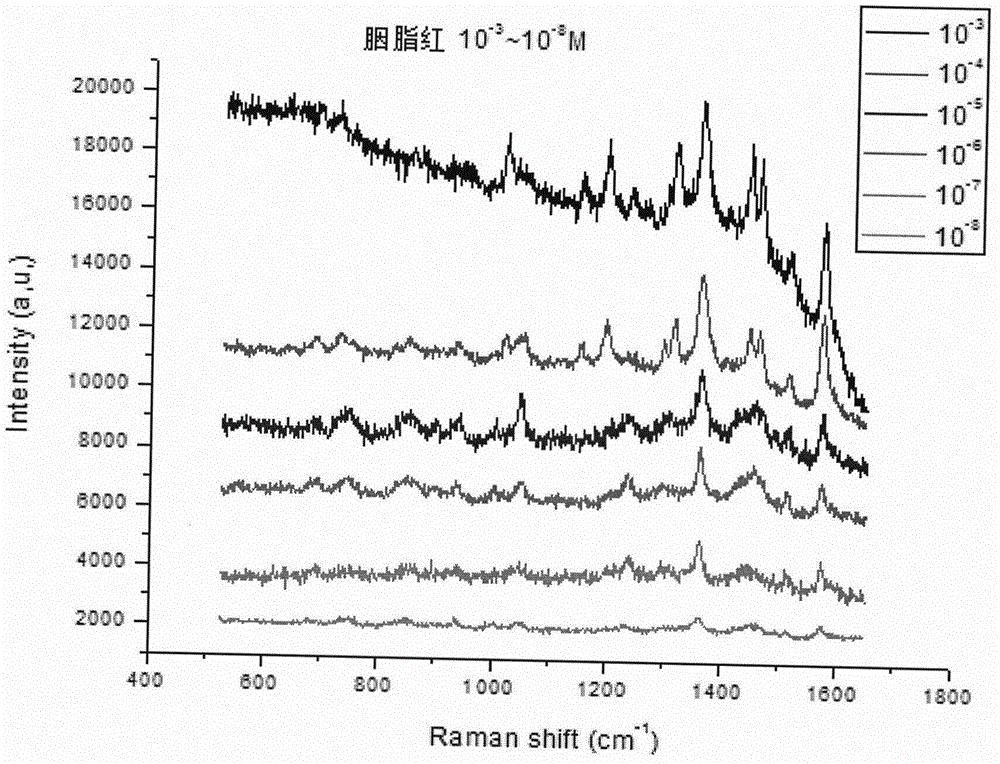

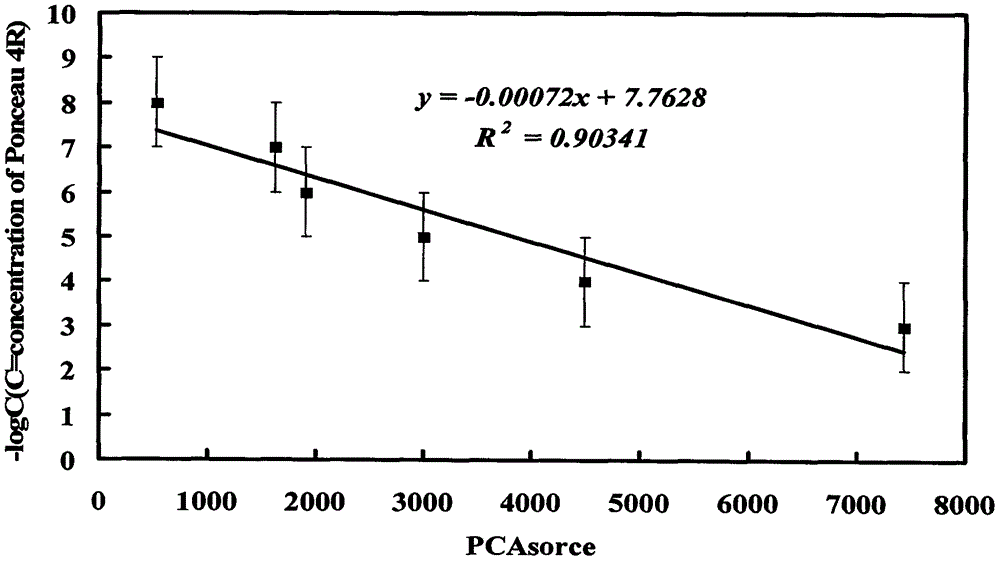

[0029] Embodiment: the detection of food colorant carmine

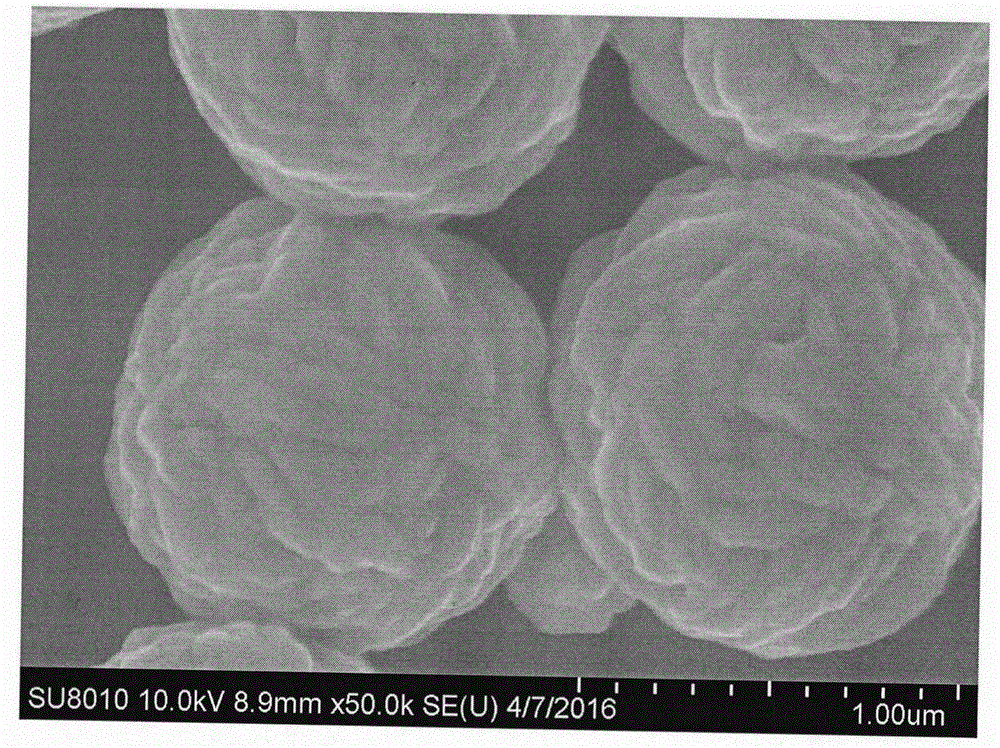

[0030] Step 1: Preparation of flower-shaped silver nanoparticles SERS substrate: Take 0.5ml of 1mol / L silver nitrate solution, 2mL of 1% polyvinylpyrrolidone solution and 15mL of deionized water and mix them with magnetic force; stir evenly and add quickly 0.2mol / L ascorbic acid solution 1mL, continue to stir for 10min, pour it into a centrifuge tube, centrifuge at a centrifugal rate of 5000-8000r / min for 15min, pour off the supernatant, add deionized water to wash and dissolve to obtain nano-silver sol; finally The nano-silver sol was dropped on a clean silicon wafer, and vacuum-dried to obtain a flower-like nano-silver particle SERS substrate.

[0031] The second step: the preparation of carmine standard solution: take 0.06g of carmine powder and dissolve it in 100mL of deionized water to obtain 10 -3 mol / L carmine standard solution, and then diluted respectively to obtain a concentration of 10 -4 mol / L, 10 -5 mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com