Method for detecting content of dissolved methyl ethyl ketone in transformer oil

A detection method and transformer oil technology, applied in the field of power transmission and transformation, can solve the problems affecting transformers, easy escape of gas, easy adsorption of furfural by insulating paper, etc., and achieve the effect of simple operation, strong professional background, and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

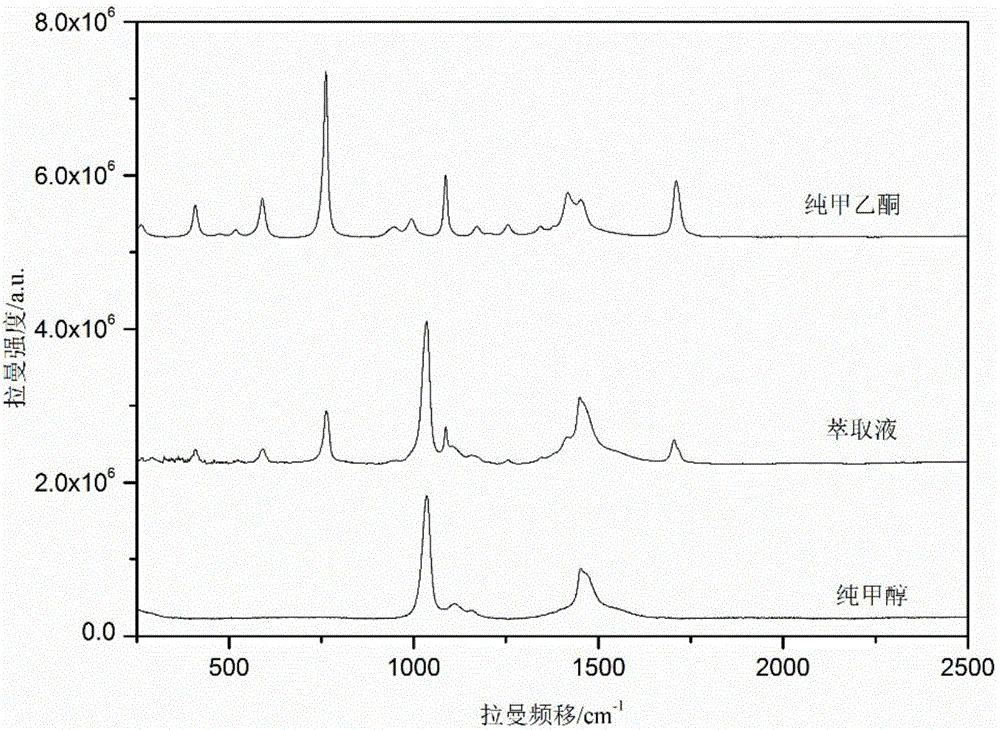

[0023] Embodiment 1 Determination of methyl ethyl ketone characteristic peak and methanol internal standard peak

[0024] Weigh 400 mg of methyl ethyl ketone and dissolve it in 1 L of methanol to obtain a methyl ethyl ketone extract.

[0025] A laser with a wavelength of 532nm and a power of 100mW was used to determine the pure Raman spectra of methyl ethyl ketone, pure methanol and methyl ethyl ketone extract, the integration time is 3s, the number of integrations is 100, the slit width is 50μm, the grating is 600l / 500nm type grating, and the detection range is 250-2500cm -1 , see the result figure 1 , choose 763cm -1 The Raman spectrum peak at place is the characteristic peak of methyl ethyl ketone, 1450 -1 The Raman spectrum peak at is the internal standard peak of methanol.

Embodiment 2

[0026] Embodiment 2 Preparation of Standard Oil Sample

[0027] Weigh 400mg of methyl ethyl ketone in 1L of transformer oil at room temperature to prepare an oil sample with a concentration of 400mg / L, which is then diluted by 2 times to form a set of standard oil samples with concentrations of 200mg / L, 100mg / L and 50mg / L respectively; Enrich the concentration gradient, and dilute the 50mg / L standard oil sample to obtain a 20mg / L standard oil sample.

Embodiment 3

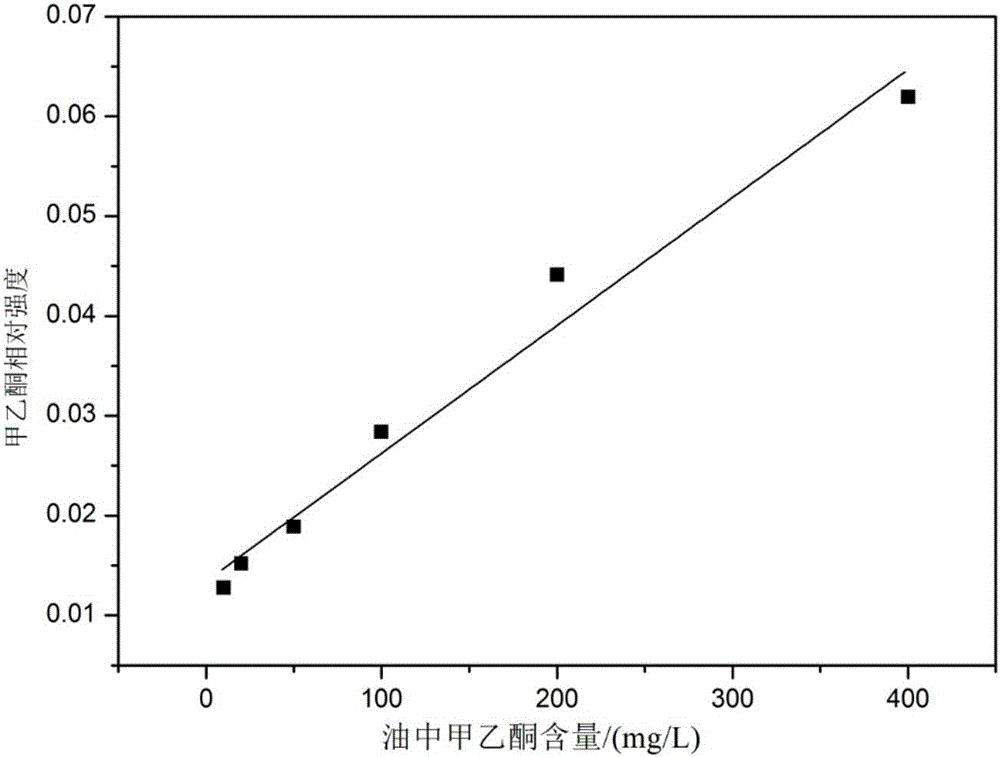

[0028] Embodiment 3 methyl ethyl ketone content determination

[0029] Step (1): respectively place 40mL of the standard oil samples of various concentrations prepared in Example 2 and 4mL of methanol in a 50mL brown Erlenmeyer flask with a stopper, stir for 5min under a magnetic constant temperature at 30°C, mix well and pour the mixture into 50mL In a centrifuge tube, centrifuge at a speed of 6000r / min for 5min, and take the methanol layer for later use;

[0030] Step (2): The methanol layer obtained in step (1) is placed in a 751-10mm type quartz cuvette, a 532nm wavelength laser is selected, the laser power is 100mW, the integration time is 3s, the number of integration times is 50, and the slit width is 50 μm, select 600l / 500nm type grating, measure the Raman spectrogram of the standard oil sample methanol layer of each concentration prepared in step (1); use MATLAB software to remove miscellaneous peaks, baseline adjustment and smoothing to the Raman spectrogram After n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com