Polarization splitting prism gluing process

A polarizing beam splitting prism and process technology, applied in prisms, polarizing elements, optics, etc., can solve the problems of brightness difference, affect the color uniformity of light-colored pictures, etc., achieve sharp edges, excellent surface appearance quality, reduce glue bubbles and The effect of scratches and blemishes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

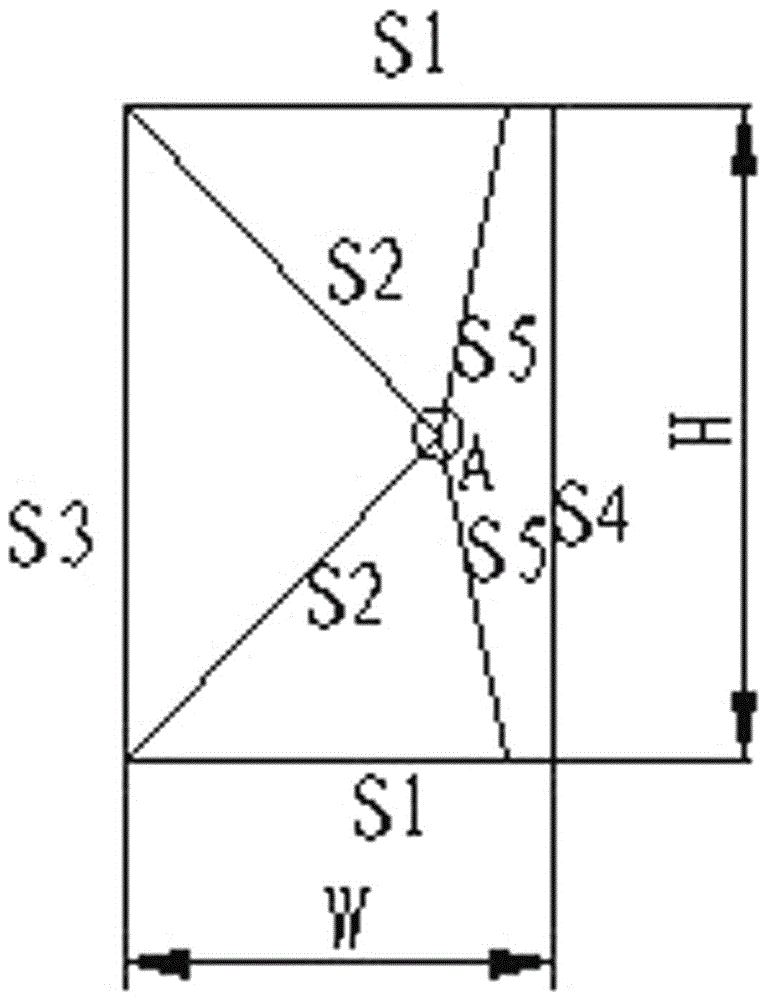

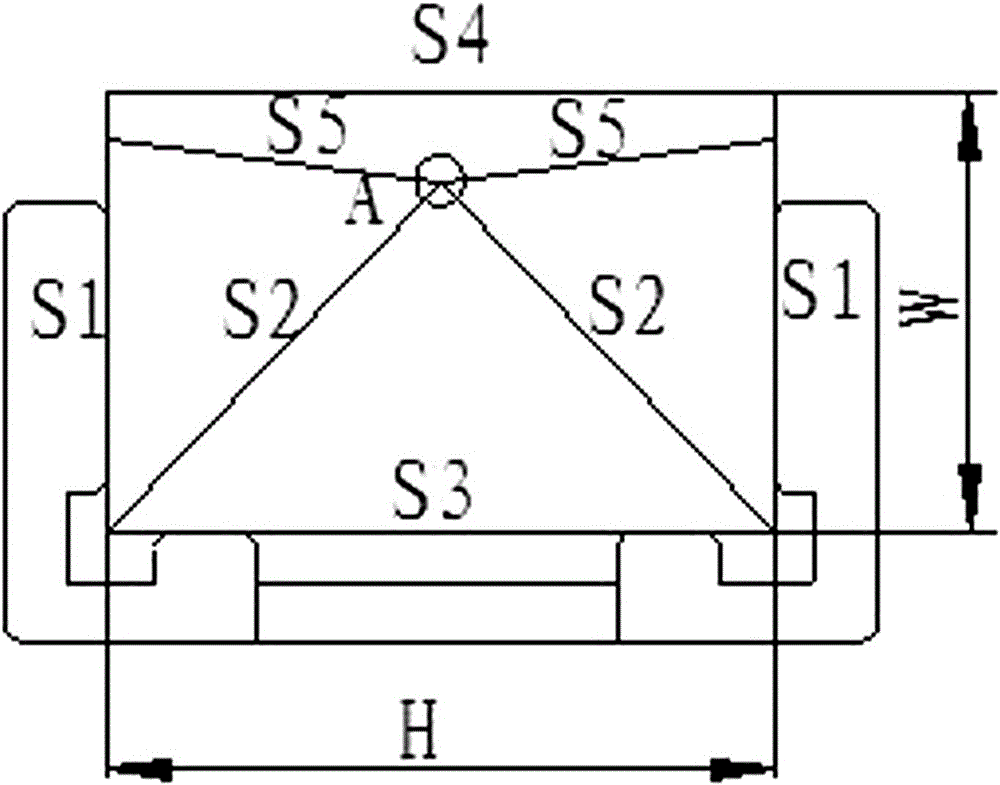

[0024] Such as figure 1 , figure 2 , image 3 As shown, the overall processing technology of the polarizing beam splitting prism is as follows: milling-polishing-coating-gluing.

[0025] The gluing process is to process and shape the triangular prisms with qualified dimensions, angles, appearance quality and matching PBS film characteristics and optical constants according to the following steps:

[0026] (1) dispensing

[0027] Dispense glue on the S2 surface of the two small triangular prisms coated with PBS film. The glue point is a circle with a diameter of 2mm to 10mm and a number of 1 to 10;

[0028] (2) Glue removal

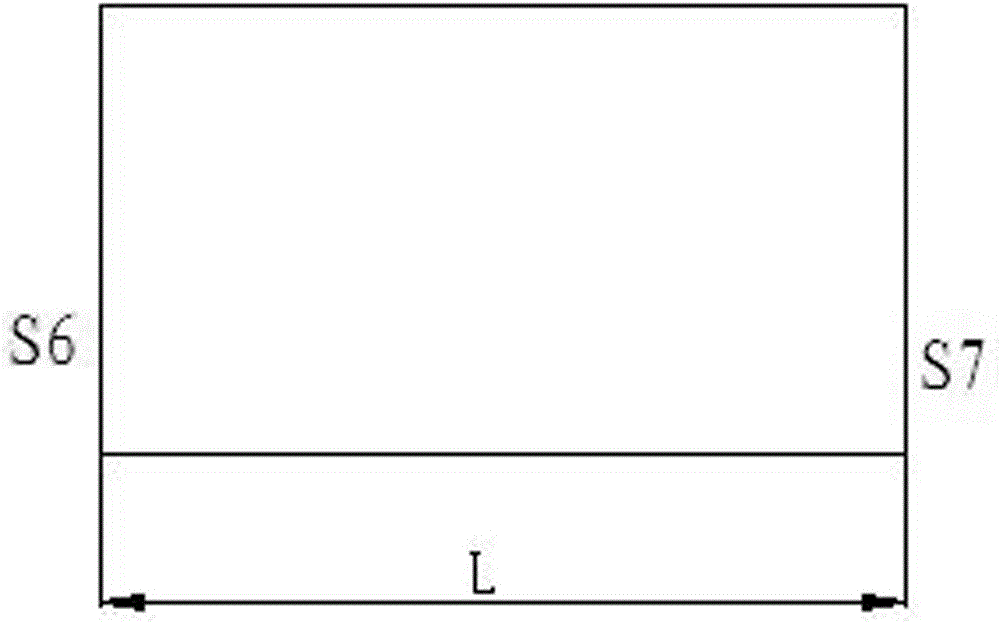

[0029] Combine the S2 surface of the small triangular prism with the S2 surface of the large triangular prism, manually remove the glue from one end of the S6 surface to the one end of the S7 surface, remove the glue bubbles, and let the glue evenly cover the S2 surface;

[0030] (3) Adjust the glue size and position

[0031] Put 3 triangular prisms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com