Optical system for miniaturization high-precision star sensor

A technology for optical systems and star sensors, applied in the field of optical engineering and optical systems for star sensors, can solve the problems of large volume and weight, large volume and weight, unfavorable light weight of star sensors, etc., and achieve low difficulty in parts processing , excellent absolute distortion, and good space environment adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The star sensor is generally composed of a hood, an optical system, a detector assembly and its circuit, a data processing circuit, a secondary power supply, software (system software, application software, and star catalog), a main structure, and a reference mirror.

[0027] The star sensor uses an optical system to converge the energy of the star target, and the converged star point energy is imaged on the star sensor detector for subsequent image processing and attitude data output. Therefore, the imaging quality, volume and weight, and space environment adaptability of the optical system are the key indicators for evaluating the optical system of the star sensor.

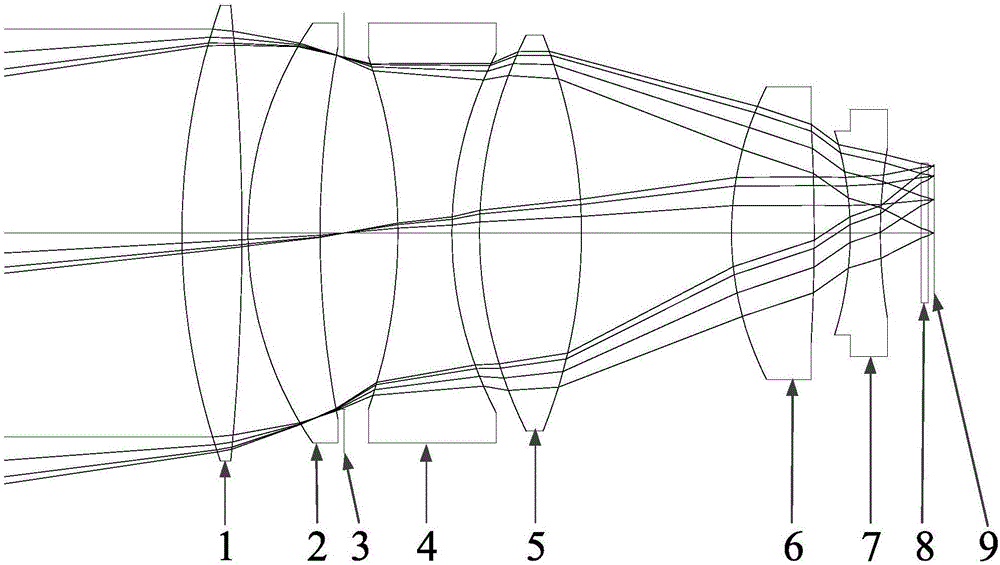

[0028] like figure 1 As shown, the optical system of the present invention is composed of six lenses, and the optical system includes a first lens 1, a second lens 2, an aperture stop 3, a third lens 4, a fourth lens 5, and a fifth lens 6 from left to right , the sixth lens 7, the detector protection gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com