A uniform optical needle focusing microstructure and design method

A design method and microstructure technology, applied in the field of micro-nano optics, can solve the problems of large lateral beam width limitation, complex focusing optical system, and high cost, and achieve the effect of flexible design method, simple system, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

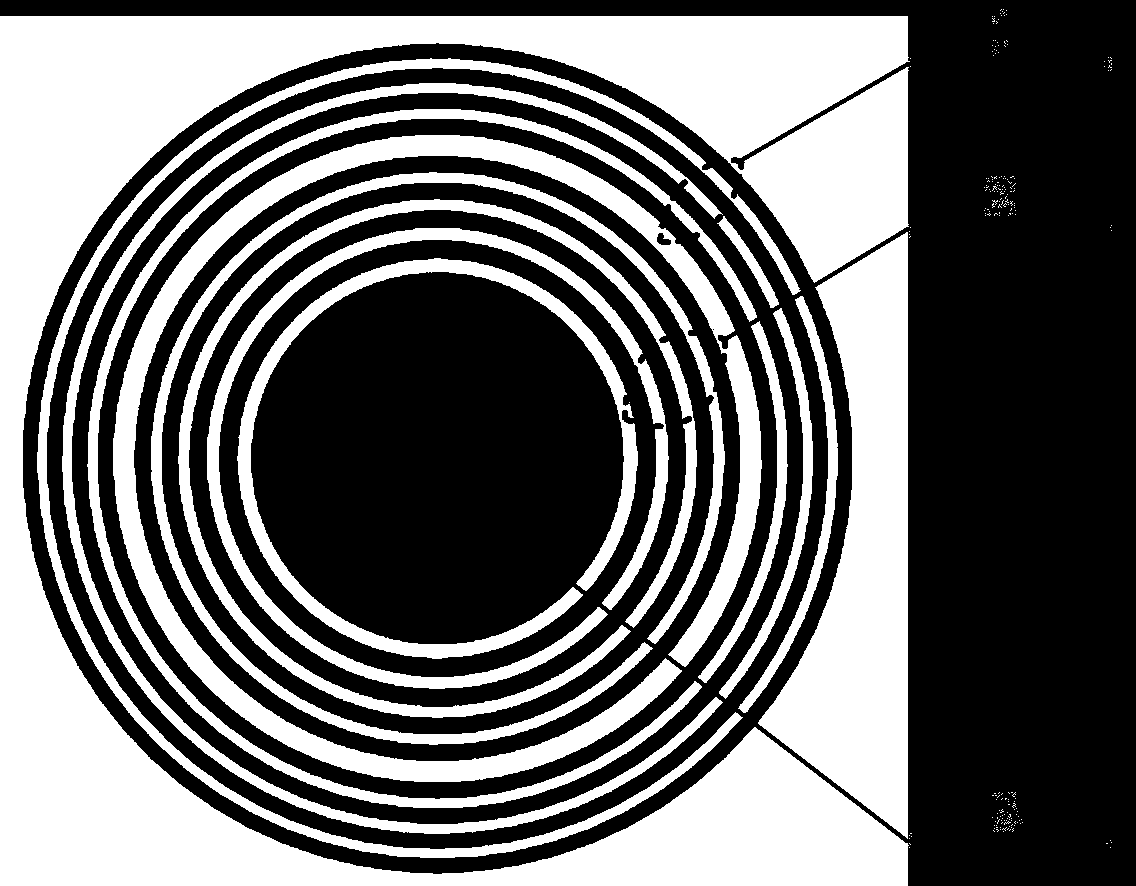

[0037] use figure 1 The shown microstructure ring plate directly focuses the uniform laser beam, and modulates it in a specific area on the rear surface of the ring plate to generate a uniform thin beam. The vector angle spectrum (Vectorial Angular Spectrum, VAS) theory is used to analyze the light field propagation.

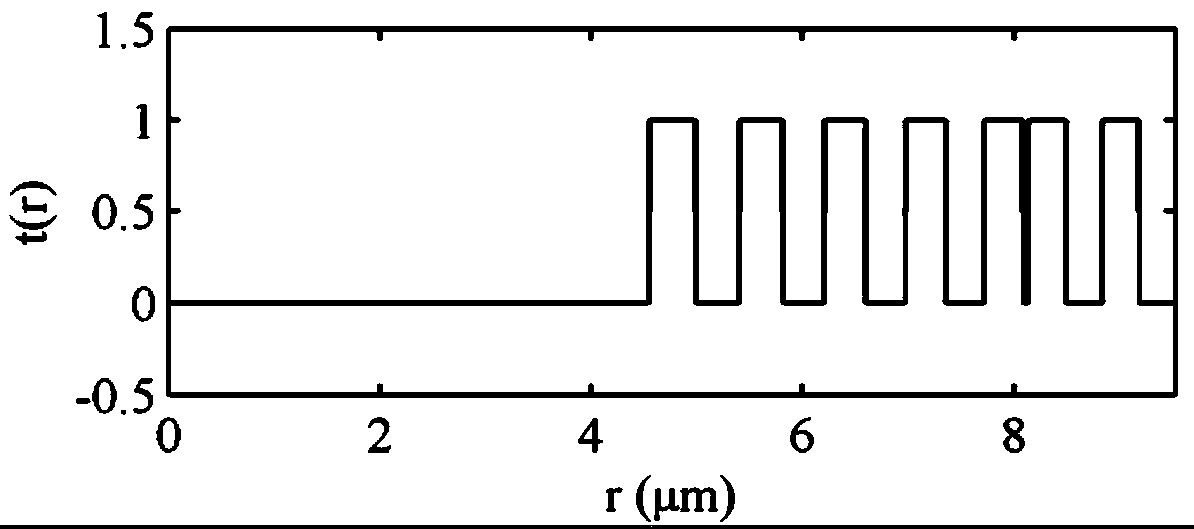

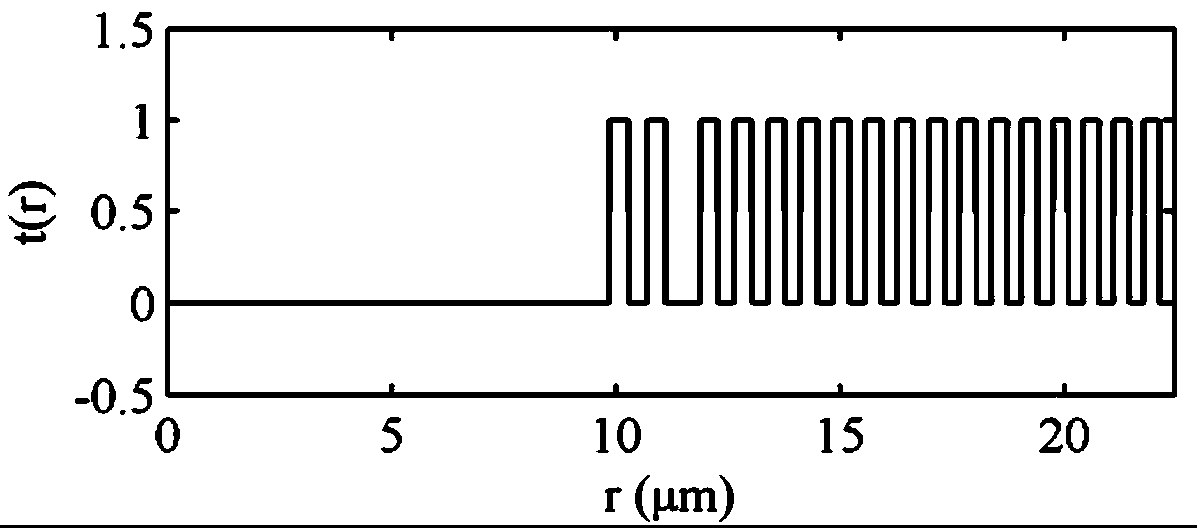

[0038] (1) Standard Fresnel zone plate

[0039] Let the wavelength of the illuminating laser beam be λ 0 , the refractive index of the working medium where the Fresnel Zone Plate (FZP) is located is η, then the wavelength of light in the medium is λ=λ 0 / η, the annulus radius of the standard Fresnel zone plate can be obtained as

[0040]

[0041] In the formula, n is the ordinal number of the ring radius, and f is the main focal length. For large numerical aperture FZP, the effective numerical aperture can be defined accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com