GaN-based metal-ultrathin oxide-semiconductor composite structure nanolaser and preparation method thereof

A nano-laser, composite structure technology, applied in semiconductor lasers, lasers, laser parts and other directions, can solve the problems of metal-ultra-thin oxide-semiconductor composite structure problems, and achieve small optical mode volume and low lasing threshold. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The preparation method of the GaN-based metal-ultra-thin oxide-semiconductor composite structure nano-laser, the steps include:

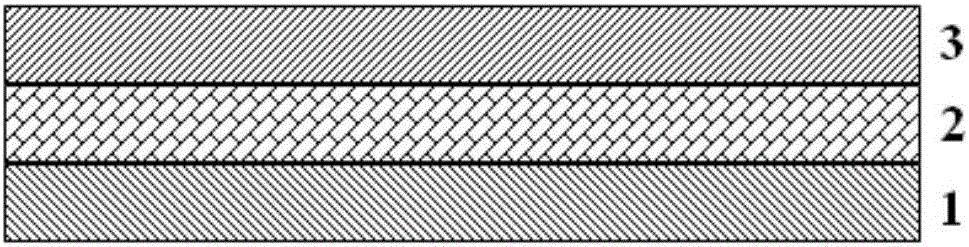

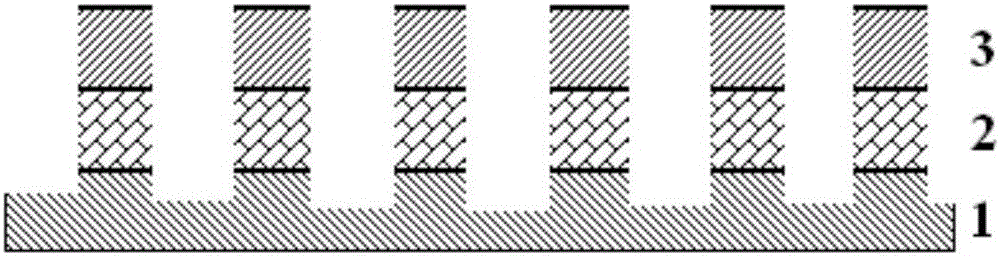

[0051] (1) A layer of SiO is grown on the InGaN / GaN quantum well epitaxial wafer 2 For the insulating layer, spin-coat PMMA glue and UV-curable glue on the surface of the insulating layer in sequence. The thickness of PMMA glue is 200nm, and the thickness of UV-curable glue is 30nm. The structure of the InGaN / GaN quantum well epitaxial wafer includes: a sapphire substrate layer , an n-type GaN layer 1 grown on the substrate layer, an In grown on the n-type GaN layer x Ga 1-x N / GaN quantum well active layer 2, grown on In x Ga 1-x The p-type AlGaN barrier layer and p-type GaN layer 3 on the N / GaN quantum well active layer, where x=0.23, the quantum well active layer emits light at a wavelength of 490nm, the number of periods of the quantum well is 10, and the p-type AlGaN barrier layer and the total thickness of the p-type GaN layer is 300...

Embodiment 2

[0062] The preparation method of the GaN-based metal-ultra-thin oxide-semiconductor composite structure nano-laser, the steps include:

[0063] (1) A layer of SiC insulating layer is grown on the InGaN / GaN quantum well epitaxial wafer, and PMMA glue and UV curing glue are spin-coated on the surface of the insulating layer in turn. The thickness of PMMA glue is 600nm, and the thickness of UV curing glue is 300nm. InGaN / GaN quantum In the well epitaxial wafer, x=0.35, the quantum well active layer emits light at a wavelength of 530nm, the number of periods of the quantum well is 15, and the total thickness of the p-type AlGaN barrier layer and the p-type GaN layer is 500nm;

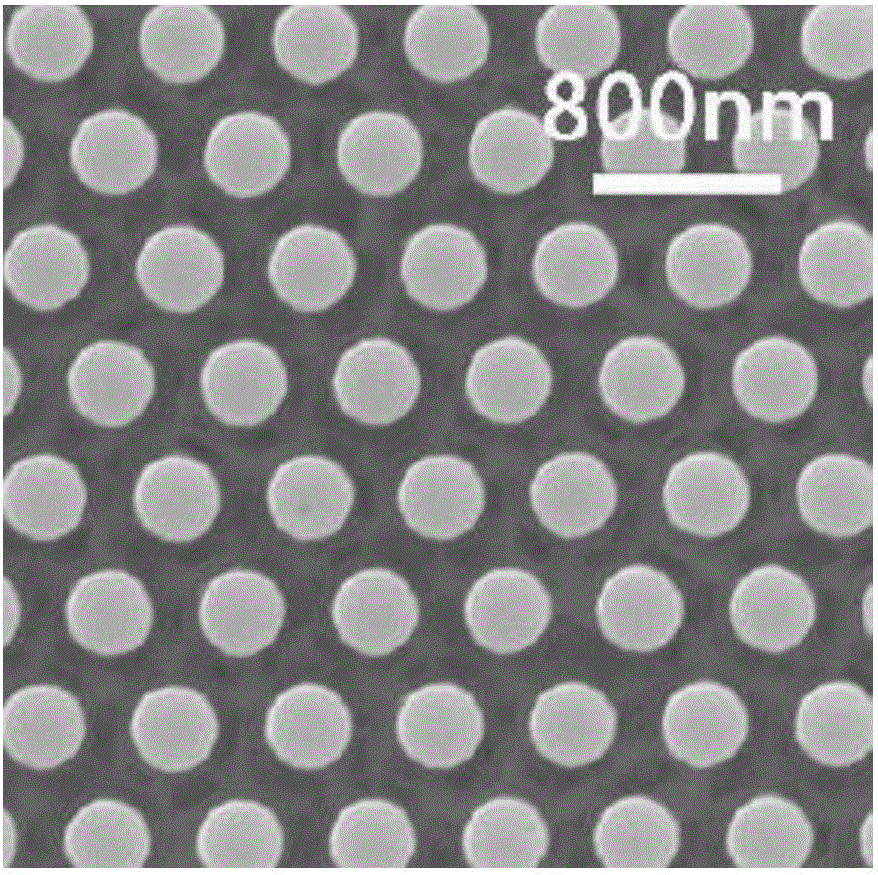

[0064] (2) Using UV soft nanoimprinting technology, a soft template is used to form a large-area ordered nano-elliptical column array on the UV-cured adhesive layer. The long-axis diameter of the nano-elliptical column is 240nm, the short-axis diameter is 160nm, and the period is 550nm. , arranged in hexago...

Embodiment 3

[0074] The preparation method of the GaN-based metal-ultra-thin oxide-semiconductor composite structure nano-laser, the steps include:

[0075] (1) A layer of SiC insulating layer is grown on the InGaN / GaN quantum well epitaxial wafer, PMMA glue and UV curing glue are spin-coated on the surface of the insulating layer in turn, the thickness of PMMA glue is 400nm, and the thickness of UV curing glue is 150nm. InGaN / GaN quantum In the well epitaxial wafer, x=0.20, the light emission wavelength of the active layer of the quantum well is 480nm, the period number of the quantum well is 12, and the total thickness of the p-type AlGaN barrier layer and the p-type GaN layer is 400nm;

[0076](2) Using UV soft nanoimprinting technology, a soft template is used to form a large-area ordered nano-elliptical column array on the UV-cured adhesive layer. The long-axis diameter of the nano-elliptical column is 240nm, the short-axis diameter is 160nm, and the period is 550nm. , arranged in hex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com