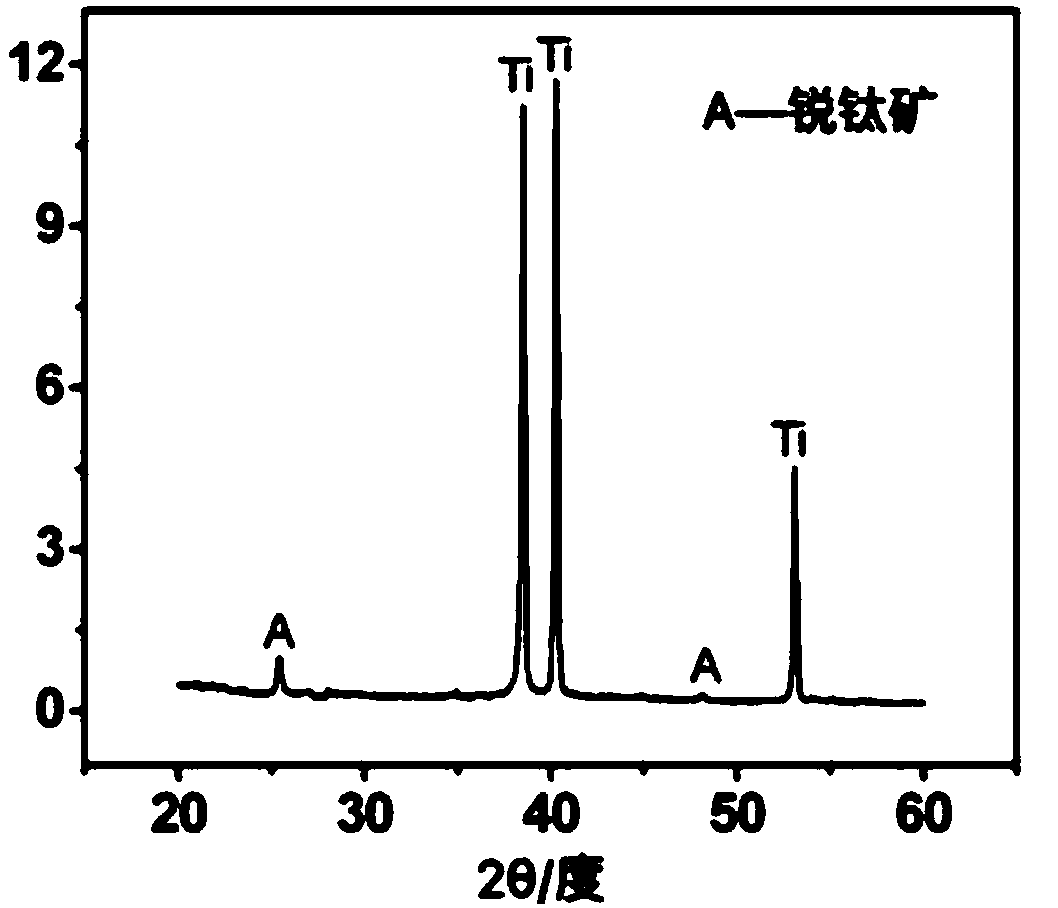

A method for preparing titanium dioxide nanotubes by two-step anodic oxidation

An anodizing, titanium dioxide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as low bonding strength and irregular surface of nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Grind and polish a titanium sheet with a size of 10mm*10mm*1mm with emery paper with a particle size of 800 mesh, then use a mixed solution of acetone:ethanol=1:1 (volume ratio) to sonicate for 10 minutes, rinse with ultrapure water, and then clean the The titanium sheet was soaked in 20mL of 12M HCl solution, the temperature was raised to 110°C at a rate of 10°C / min, and the acid cooking time was 30min, and then cooled to room temperature at 10°C / min. 2 Conditions of drying to obtain a new titanium electrode.

[0029] The obtained nascent titanium electrode was placed in a two-electrode anodizing device, and a self-made ruthenium-titanium-tin electrode was used as a cathode, and 100 mL of 89.5wt.% ethylene glycol, 0.5wt.% NH 4 Electrolyte composed of F and 10wt.% ultrapure water, anodized at room temperature through direct current, and the current density is controlled at 1mA / cm 2 , the oxidation time is 5min; take out the oxidized electrode, and use 10mL of 2M HCl so...

Embodiment 2

[0032] Grind and polish a titanium sheet with a size of 10mm*10mm*1mm with emery paper with a particle size of 800 mesh, then use a mixed solution of acetone:ethanol=1:1 (volume ratio) to sonicate for 10 minutes, rinse with ultrapure water, and then clean the The titanium sheet was immersed in 20mL of 12M HCl solution, the temperature was raised to 110°C at a rate of 10°C / min, and the acid cooking time was 1h, and then lowered to room temperature. 2 Conditions of drying to obtain a new titanium electrode.

[0033] The obtained nascent titanium electrode was placed in a two-electrode anodizing device, and a self-made ruthenium-titanium-tin electrode was used as a cathode, and 100mL of 89wt.% ethylene glycol, 1wt.% NH 4 Electrolyte composed of F and 10wt.% ultrapure water, anodized at room temperature through direct current, and the current density is controlled at 1mA / cm 2 , the oxidation time is 5min; take out the oxidized electrode, and use 10mL of 2M HCl solution to sonicat...

Embodiment 3

[0036] Grind and polish a titanium sheet with a size of 10mm*10mm*1mm with emery paper with a particle size of 800 mesh, then use a mixed solution of acetone:ethanol=1:1 (volume ratio) to sonicate for 10 minutes, rinse with ultrapure water, and then clean the The titanium sheet was soaked in 20mL of 12M HCl solution, the temperature was raised to 110°C at a rate of 10°C / min, and the acid cooking time was 1min, and then lowered to room temperature. 2 Conditions of drying to obtain a new titanium electrode.

[0037] The obtained nascent titanium electrode was placed in a two-electrode anodizing device, and a self-made ruthenium-titanium-tin electrode was used as a cathode, and 100 mL of 89.5wt.% ethylene glycol, 0.5wt.% NH 4 Electrolyte composed of F and 10wt.% ultra-pure water, through direct current for anodic oxidation, the control current density is 2mA / cm 2 , the oxidation time is 5min; take out the oxidized electrode, and use 10mL of 2M HCl solution to sonicate for 10min;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com