Rolled strip pulse forming line based on high energy storage density liquid medium

A technology with high energy storage density and liquid medium, applied in the direction of energy storage element generating pulse, electric pulse generator circuit, etc., can solve the problems of irreversible breakdown, small output electric pulse width, large volume and weight, etc. The effect of shielding, increasing the width of the electrical pulse, and rationally using the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

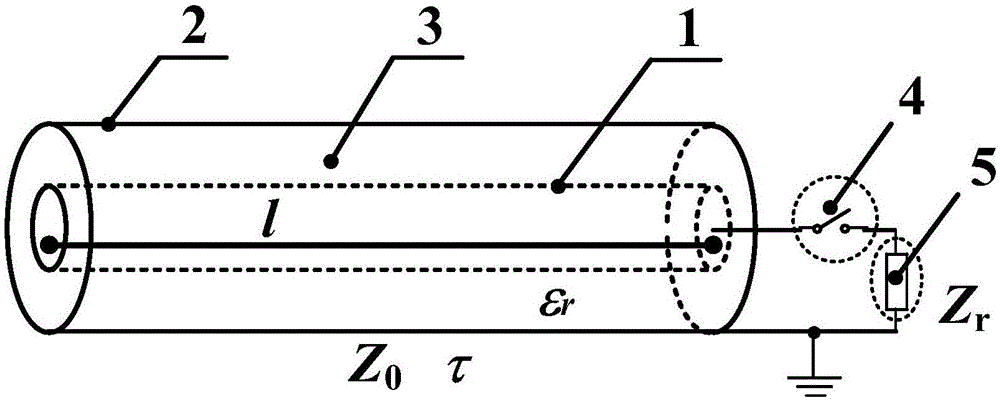

[0043] figure 1 It is the working principle diagram of the straight tube pulse forming line introduced by Liu Xisan in the book "High Power Pulse Technology". Among them, 1 is a high-voltage conductor (length l), 2 is a grounding conductor, Z 0 and τ are respectively the intrinsic impedance and electrical length of the pulse forming line, 3 is the energy storage medium (permittivity is ε r ), 4 is a closed switch, and 5 is a load (impedance is Zr). Pages 41-45 of the book explain in detail that the electrical length τ of the pulse-forming line is proportional to the length l of the high-voltage conductor 1 and the dielectric constant ε of the energy storage medium 3 r . The pulse forming line in the high-power pulse driving source can generate quasi-square wave electric pulse with the cooperation of the switch, which has important application value. When the pulse-forming line intrinsic impedance Z 0 When it is equal to the load impedance, a quasi-square wave electric pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com