Drive circuit

A technology for driving circuits and circuit output, applied in circuits, electrical components, electronic switches, etc., can solve problems such as large EMI noise, and achieve the effects of eliminating overshoot and oscillation, high efficiency, and speeding up the flipping speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

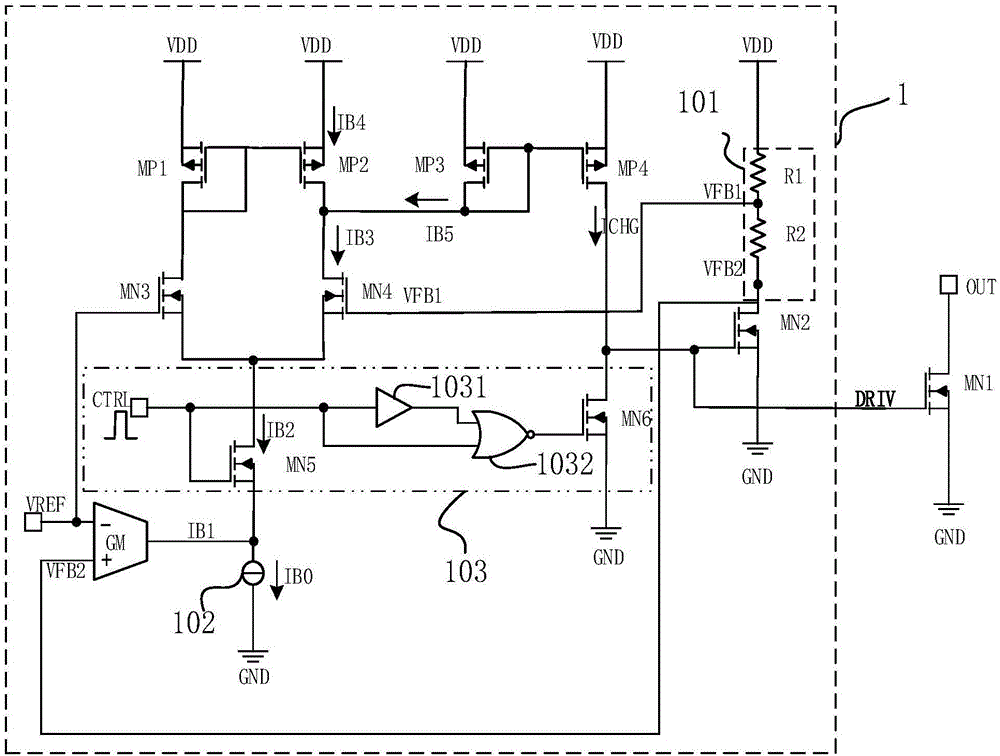

[0028] Such as figure 2 and image 3 As shown, a driving circuit 1 is used to drive an N-type power switch tube MN1. The driving circuit 1 includes a circuit output terminal DRIV, a transconductance amplifier GM, a constant current source 102, a first PMOS transistor MP1, a second PMOS transistor MP2, a third PMOS transistor MP3, a fourth PMOS transistor MP4, a second NMOS transistor MN2, and a second PMOS transistor MP4. Three NMOS transistors MN3, a fourth NMOS transistor MN4, a voltage divider circuit 101 and a power transistor shutdown circuit 103; the voltage divider circuit 101 includes a first resistor R1 and a second resistor R2. The power transistor shutdown circuit 103 includes a fifth NMOS transistor MN5 , a sixth NMOS transistor MN6 , a delay circuit 1031 and a NOR gate 1032 . Wherein, the second NMOS transisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com