Method for producing high-concentration alcohol

A manufacturing method and high-concentration technology are applied to a high-concentration alcohol manufacturing device, in the field of producing high-concentration alcohol from a water-alcohol mixture, which can solve problems such as difficult-to-purify organic compounds, and achieve the effects of high purity and overall high efficiency of the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

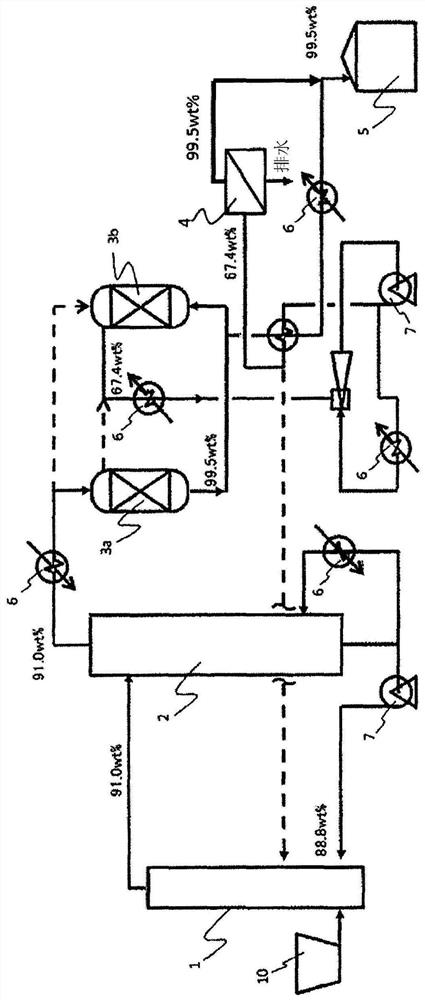

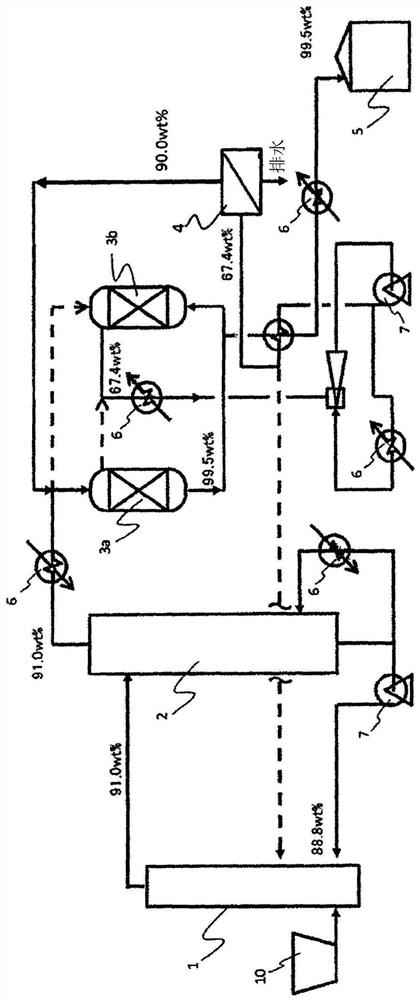

Method used

Image

Examples

Embodiment 1

[0193] As an aqueous reaction mixture for hydrothermal synthesis, the following were prepared.

[0194] to aluminum hydroxide (containing Al 2 o 3 53.5% by mass, manufactured by Aldrich) were added 1 mol / L-KOH aqueous solution and water, mixed and stirred to dissolve, and a solution was prepared.

[0195] Colloidal silica (manufactured by Nissan Chemical Co., Ltd., SNOWTEX-40) was added thereto, and stirred for 2 hours to prepare an aqueous reaction mixture.

[0196] The composition (molar ratio) of the aqueous reaction mixture is SiO 2 / Al 2 o 3 / KOH / H 2 O=1 / 0.125 / 0.7 / 80, SiO 2 / Al 2 o 3 =8.

[0197] As the inorganic porous support, a porous alumina tube (outer diameter: 12 mm, inner diameter: 9 mm) was used.

[0198] 5.00 g of NaOH and 100 g of water were mixed with 10.0 g of proton-type Y-type zeolite (HY (SAR=5), manufactured by Catalyst Chemicals Co., Ltd.), and the resulting mixture was heated at 100° C. for 7 days, filtered, washed with water, and dried. , t...

Embodiment 2

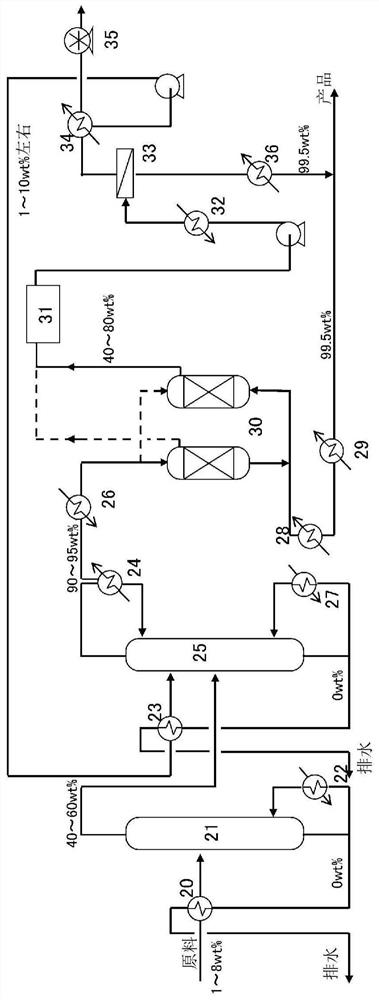

[0206] Use with SiO 2 / Al 2 o 3 The zeolite-membrane complex of the zeolite membrane of the CHA-type zeolite with a molar ratio of 7 is used to make water selectively from the separated liquid at 100°C, that is, hydrous ethanol (water / ethanol=49 / 51% by mass) by pervaporation. Permeable membrane separation process.

[0207] A schematic diagram of the apparatus used in pervaporation is shown in Figure 7 .

[0208] Figure 7 Among them, the liquid to be separated (volume 4.0 L) located in the raw material tank 11 is transported to the membrane separation device 14 by the circulation pump 12 at a flow rate of 1.0 L / min.

[0209] The liquid to be separated was heated to 100° C. by an electric heater 13 before being introduced into the membrane separation device 14 . The inside of the zeolite membrane complex in the membrane separation device 14 is depressurized by a vacuum pump 19 so that the pressure difference between the outside in contact with the liquid to be separated ...

Embodiment 3

[0213] In the same manner as in Example 2, a membrane separation step of selectively permeating water from 100° C. hydrous ethanol (water / ethanol=32 / 68% by mass) was performed by the pervaporation method. The permeation flux of water is 10.4kg / (m 2 • h), the concentration of water in the permeate was 99.99% by mass. The measurement results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com