Gas turbine, combined cycle plant, and method of starting a gas turbine

A technology for gas turbines and turbines, which is applied in the direction of gas turbine devices, combined combustion mitigation, and engine start-up, which can solve the problems of reduced driving force recovery efficiency and reduced performance of gas turbines, and achieve a small degree of reduction and the effect of suppressing thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the gas turbine, the combined cycle unit, and the start-up method of the gas turbine according to the present invention will be described in detail below with reference to the accompanying drawings. In addition, this invention is not limited to this embodiment, Moreover, when it has several embodiment, the aspect which combined each embodiment is also included.

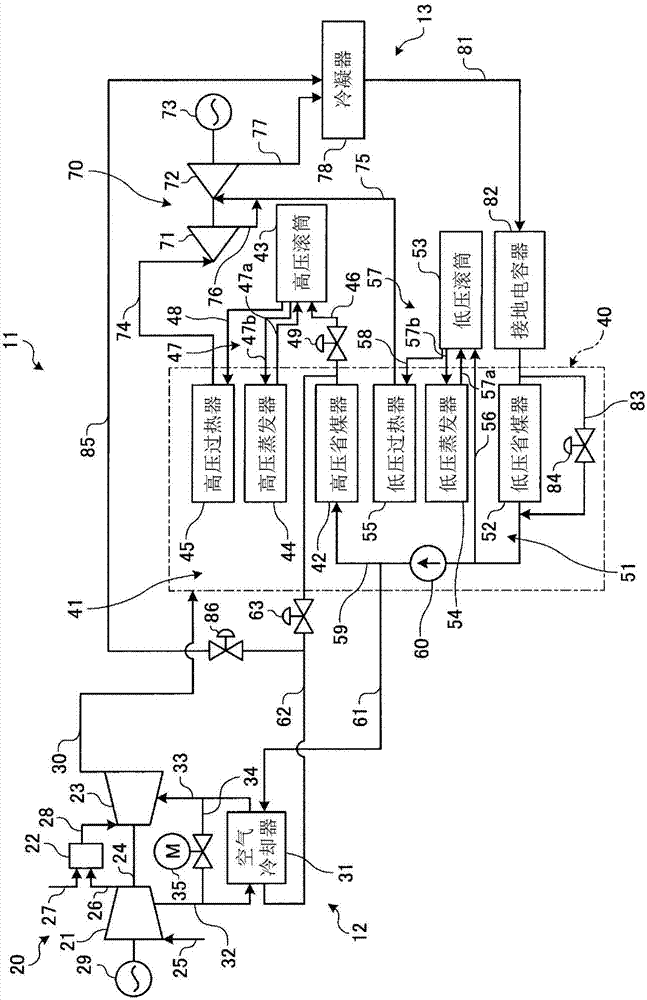

[0038] figure 1 is a schematic configuration diagram showing a gas turbine combined cycle plant according to the present embodiment.

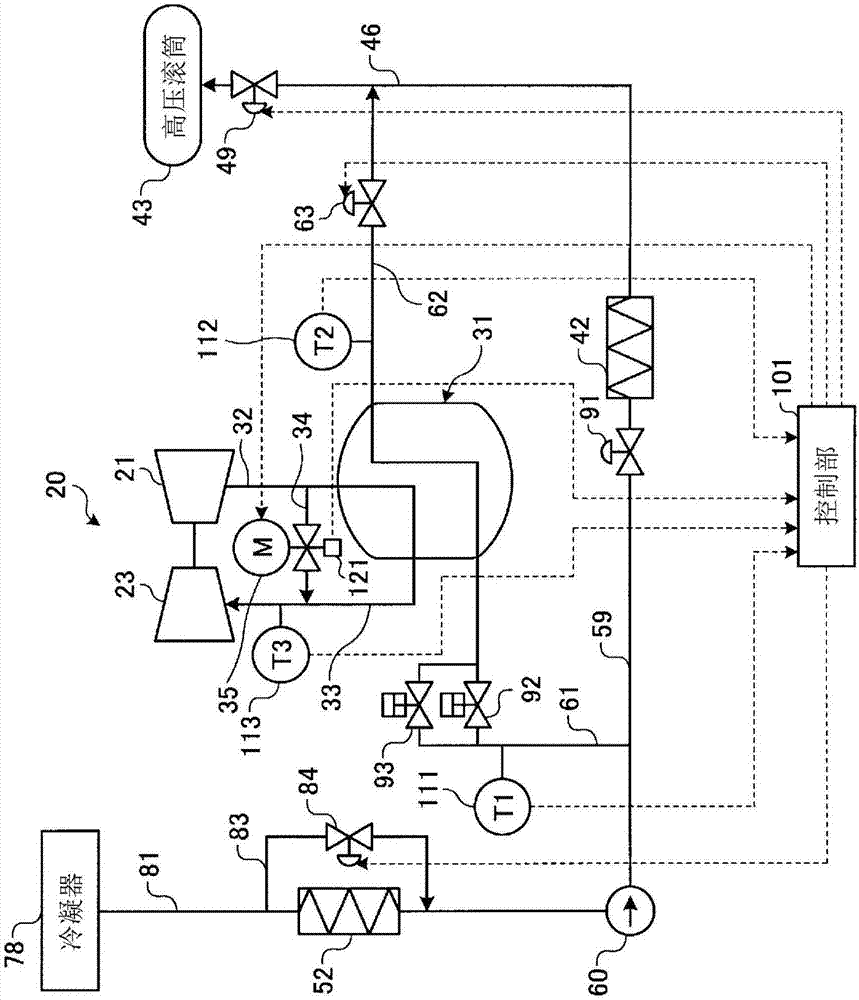

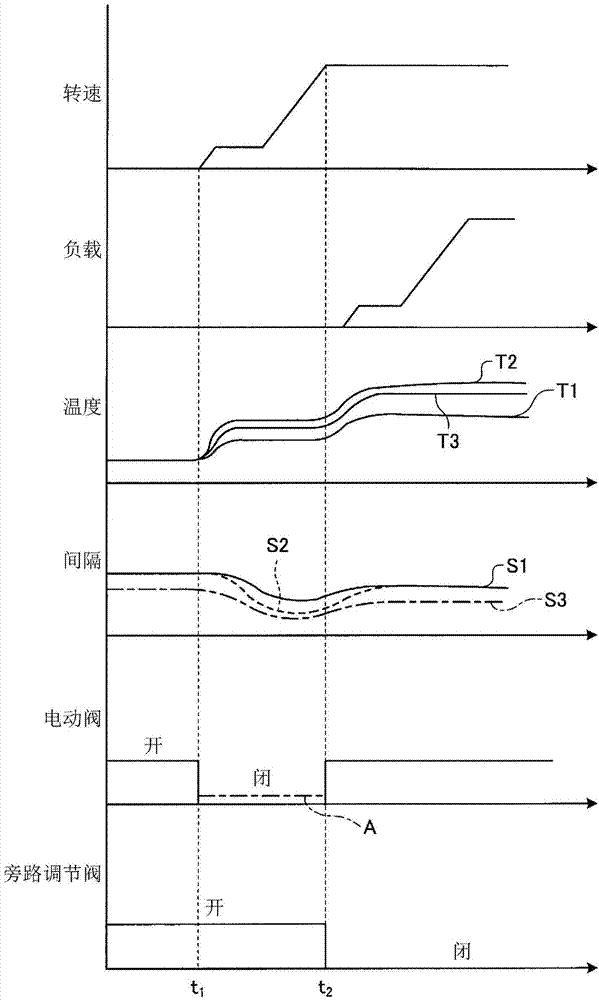

[0039] In this example, if figure 1 As shown, the gas turbine combined cycle unit 11 is composed of a gas turbine section 12 and a steam turbine section 13 . The gas turbine section 12 has a gas turbine 20 . This gas turbine 20 has a compressor 21 , a combustor 22 , and a turbine 23 , and the compressor 21 and the turbine 23 are integrally and rotatably connected via a rotating shaft (rotor) 24 . The compressor 21 compresses the air sucked in from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com