mask assembly

A component and mask technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of hollow pattern size change, low evaporation cover life, etc., to save damage and reduce dimensional changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

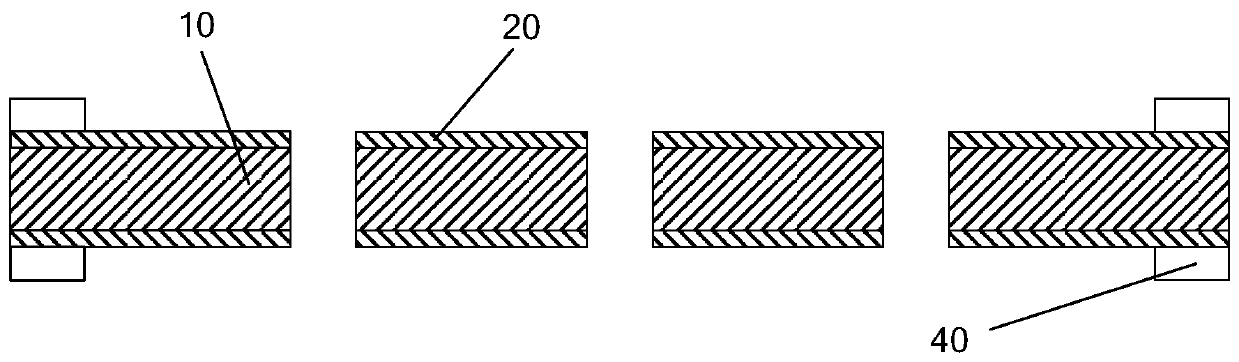

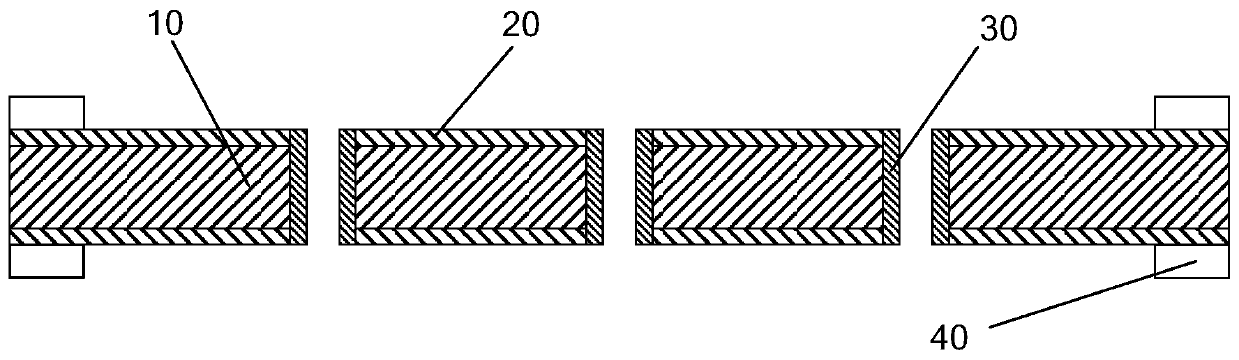

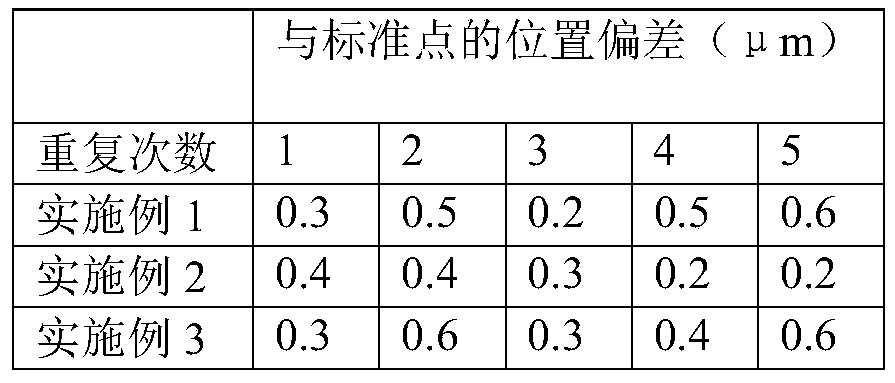

[0038] The mask assembly provided by this embodiment is as figure 1 As shown, it includes a carbon fiber material layer and a first metal layer arranged on both sides of the carbon fiber material layer, wherein the carbon fiber material layer has a first hollow area, and the carbon fiber material layer is carbon fiber cloth (model is CFS-II-200) , the first metal layer has a second hollow area corresponding to the first hollow area, the thickness is 4 μm, and the first metal layer is a nickel layer, and the thickness of the mask component is 120 μm.

Embodiment 2

[0040] The difference between this embodiment and embodiment 1 is:

[0041] The first metal layer is iron platinum (FePt 53 ) alloy layer.

Embodiment 3

[0043] The difference between this embodiment and embodiment 2 is:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com