A plasma processing device

A plasma and processing device technology, applied in the field of plasma processing devices, can solve problems such as substrate damage, inability to adapt to semiconductor manufacturing processes, and limited application range, and achieve high density, precise processing, and low electron temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

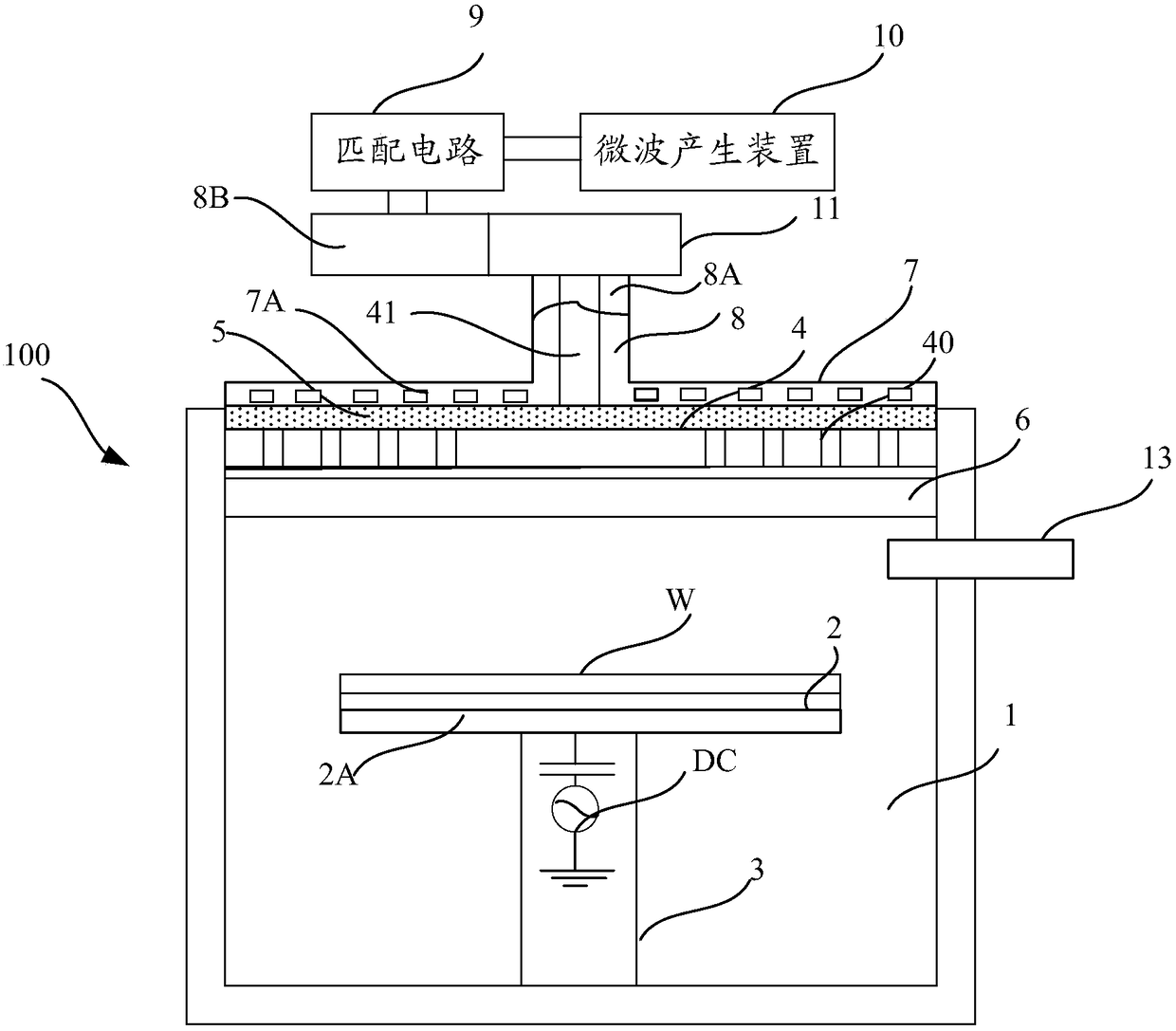

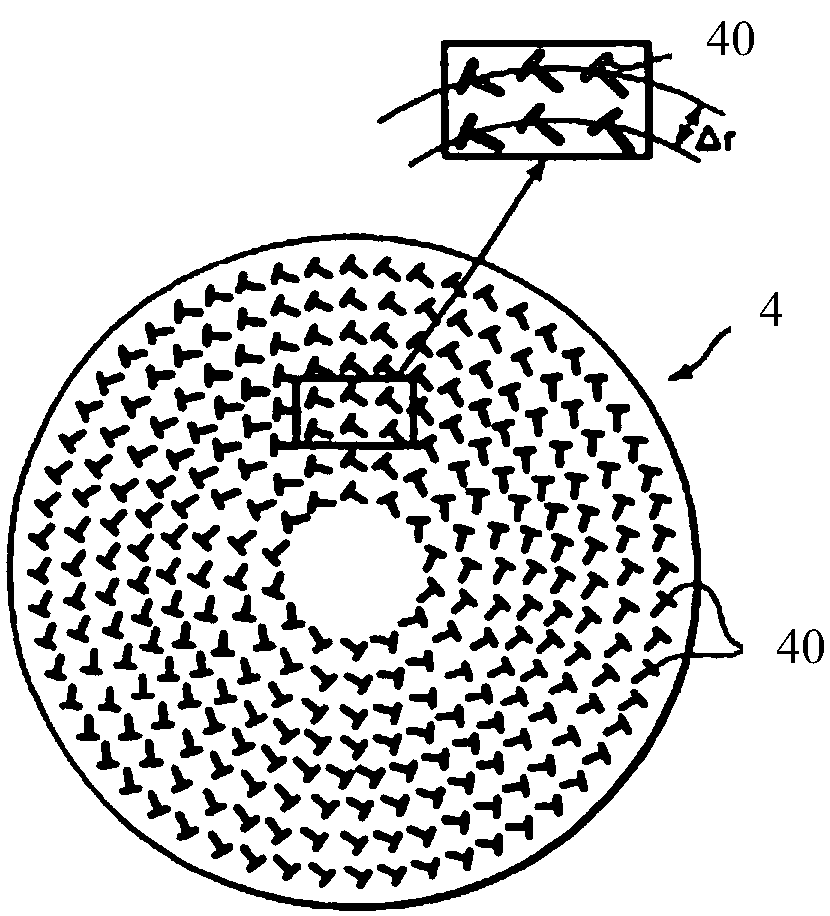

[0025] figure 1 A schematic structural diagram of a plasma processing apparatus according to an embodiment of the present invention is shown. The plasma processing device is a RLSA surface wave plasma processing device, which uses a planar antenna with a plurality of slits, especially a RLSA (Radial Line Slot Antenna) to introduce microwaves into the processing chamber, by This can generate surface wave plasma with high density and low electron temperature, and various plasma treatments, such as plasma oxidation treatment and etching, can be implemented by means of the surface wave plasma.

[0026] Such as figure 1 As shown, the plasma processing apparatus 100 has a processing chamber 1 that is a substantially cylindrical chamber 1 that is hermetically sealed and grounded. An electrostatic chuck 2 made of ceramics such as AlN for horizontally supporting an object to be processed such as a semiconductor wafer (hereinafter simply referred to as "wafer") W is provided in the pr...

Embodiment 2

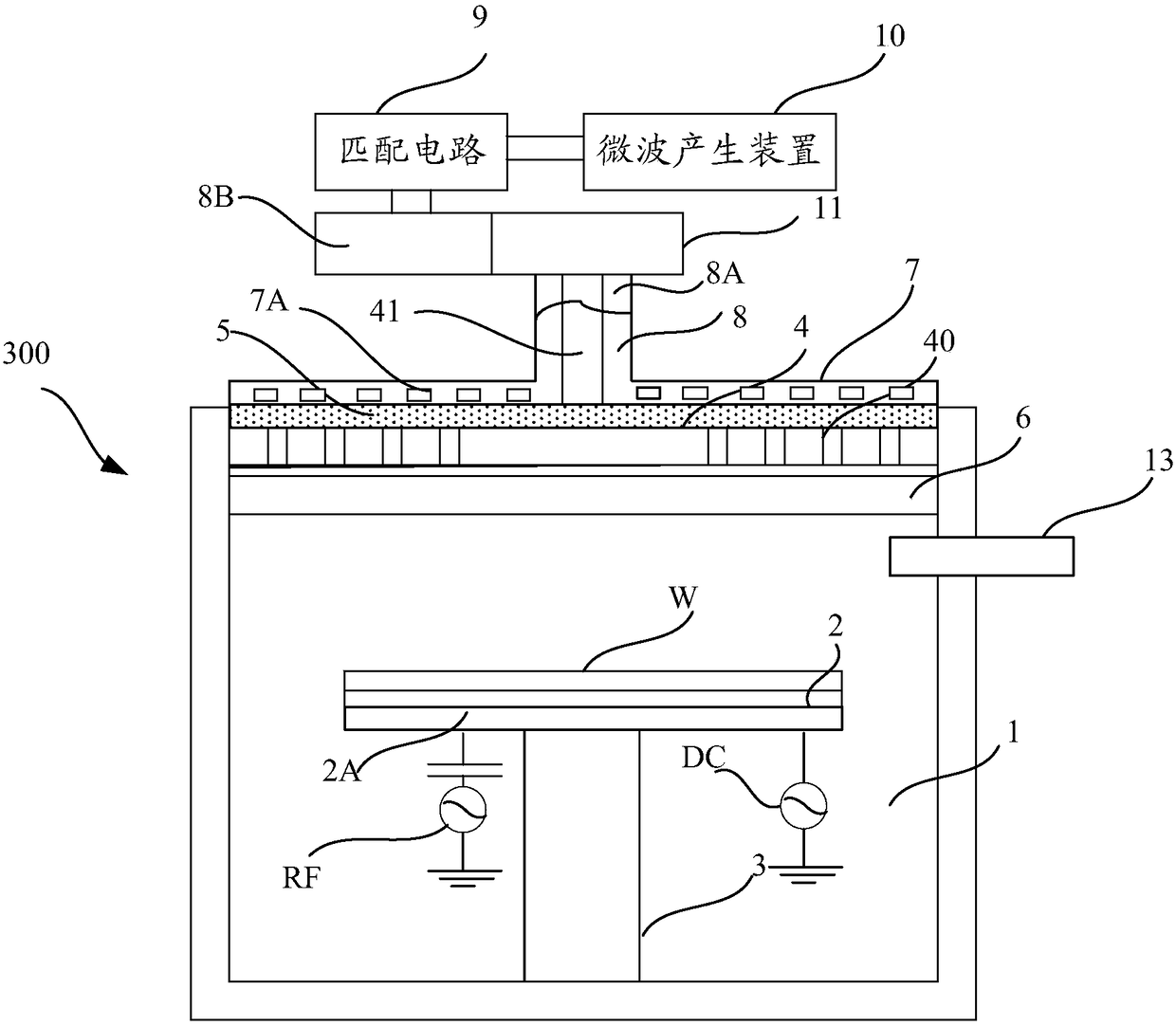

[0040] image 3 A schematic structural diagram of a plasma processing apparatus according to another embodiment of the present invention is shown. The plasma processing device is also an RLSA surface wave plasma processing device, and the RLSA surface wave plasma processing device 300 and figure 1 The shown surface wave plasma processing device 100 is similar, except that, in this embodiment, on the lower electrode plate 2A, in addition to the DC bias, a radio frequency bias RF is also applied, and the radio frequency bias RF The pulse of the microwave is synchronized with the microwave pulse generated by the microwave generating device 10, that is, the phases of the two are the same, as Figure 4 Shown in curve 1 and curve 2.

[0041] Exemplarily, in this embodiment, the frequency of the radio frequency bias RF is 13.56 MHz, which is generated by a radio frequency pulse sending device commonly used in the field, and will not be repeated here. It can be understood that, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com