Method for synthesizing composite of nickel and ferronickel layered double metal hydroxides through laser

A layered bimetallic and hydroxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of increasing catalyst cost, weakening LDHs catalytic activity and Stability and other issues, to achieve the effect of easy control, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

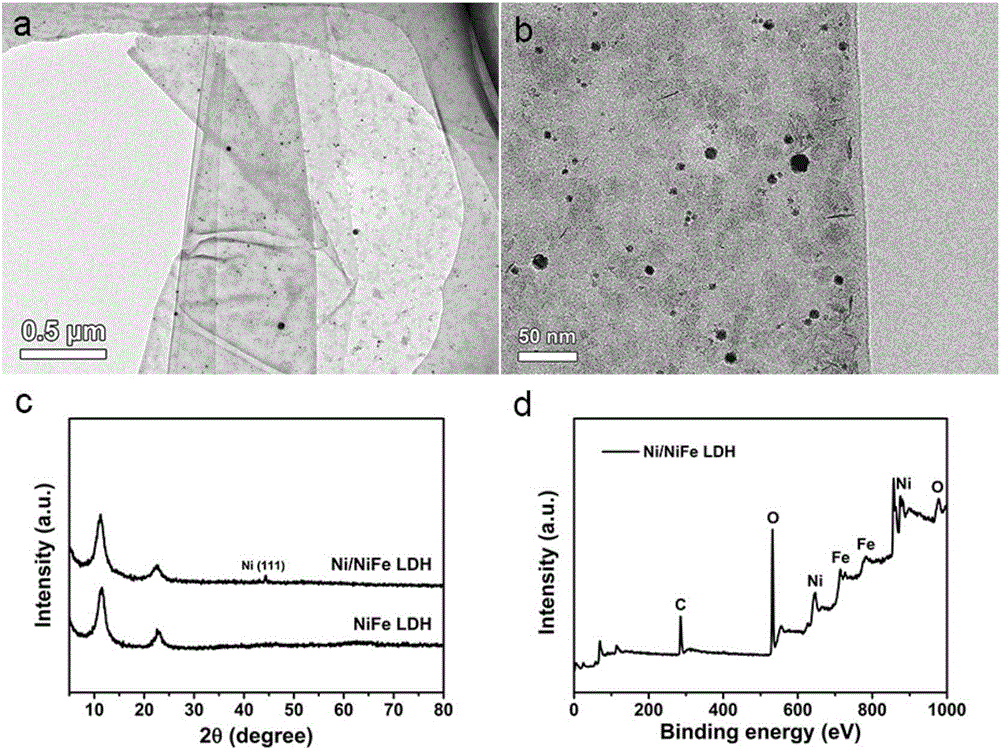

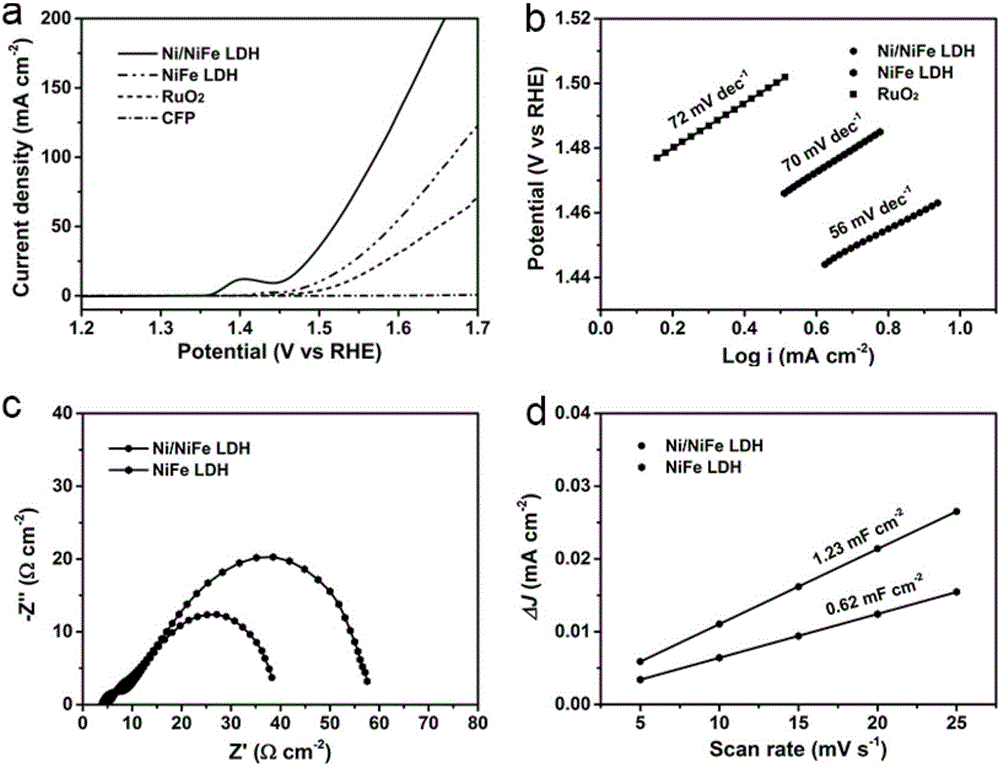

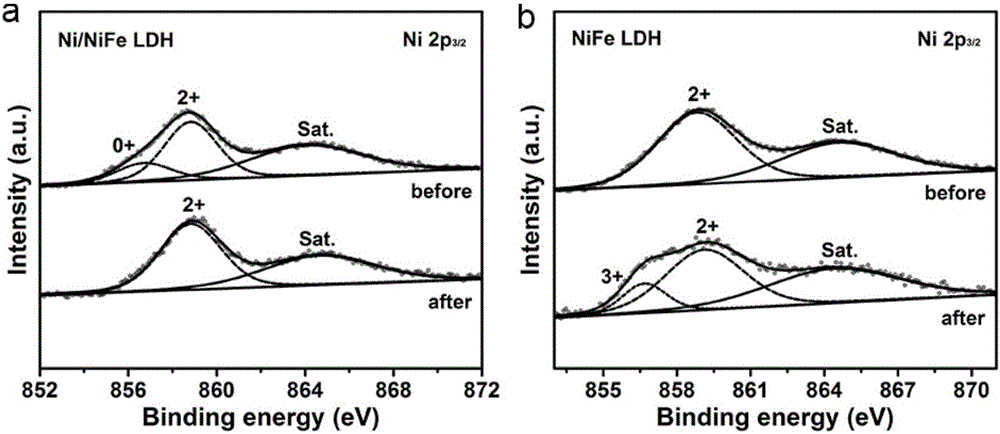

[0026] This embodiment provides a method for synthesizing nickel and nickel-iron layered double hydroxide composites by nanosecond laser ablation in liquid phase, comprising the following steps:

[0027] (1) Using the bulk nickel-iron alloy target as the raw material, the surface of the alloy target was polished with sandpaper and then ultrasonically cleaned with dilute hydrochloric acid to remove the oxide layer; then the surface of the alloy target was cleaned several times with deionized water to remove residual dilute hydrochloric acid, and then Dry the surface of the alloy target for use. Among them, the purity of the bulk nickel-iron alloy target is 99.9%.

[0028] (2) Put the dried alloy target in a 50 ml beaker, add 20 ml of 0.75M urea solution into the beaker, so that the height of the liquid surface above the alloy target is 1-1.5 cm.

[0029] (3) Start the nanosecond laser, adopt the nanosecond pulse laser of 1064 nanometer wavelength to ablate the alloy target in ...

Embodiment 2

[0036] This embodiment provides a method for synthesizing nickel and nickel-iron layered double hydroxide composites by nanosecond laser ablation in liquid phase, comprising the following steps:

[0037] (1) Using the bulk nickel-iron alloy target as the raw material, the surface of the alloy target was polished with sandpaper and then ultrasonically cleaned with dilute hydrochloric acid to remove the oxide layer; then the surface of the alloy target was cleaned several times with deionized water to remove residual dilute hydrochloric acid, and then Dry the surface of the alloy target for use. Among them, the purity of the bulk nickel-iron alloy target is 99.9%.

[0038] (2) Put the dried alloy target in a 50 ml beaker, add 20 ml of 1.5M urea solution into the beaker, so that the height of the liquid surface above the alloy target is 1-1.5 cm.

[0039] (3) Start the nanosecond laser, adopt the nanosecond pulse laser of 1064 nanometer wavelength to ablate the alloy target in t...

Embodiment 3

[0046] This embodiment provides a method for synthesizing nickel and nickel-iron layered double hydroxide composites by nanosecond laser ablation in liquid phase, comprising the following steps:

[0047] (1) Using the bulk nickel-iron alloy target as the raw material, the surface of the alloy target was polished with sandpaper and then ultrasonically cleaned with dilute hydrochloric acid to remove the oxide layer; then the surface of the alloy target was cleaned several times with deionized water to remove residual dilute hydrochloric acid, and then Dry the surface of the alloy target for use. Among them, the purity of the bulk nickel-iron alloy target is 99.9%.

[0048] (2) Place the dried alloy target in a 50 ml beaker, and add 20 ml of 6M urea solution into the beaker to make the liquid level above the alloy target 1-1.5 cm.

[0049] (3) Start the nanosecond laser, adopt the nanosecond pulse laser of 1064 nanometer wavelength to ablate the alloy target in the urea solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com